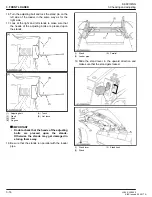

8. When pushing the quick-attach-coupler-handles

into the

locked

position, visually verify that the latch

pins rotate completely and are located underneath

the stop of the quick attach coupler.

(1) Latch pins

(2) Quick attach coupler stopper

9. When attaching different attachments, visually

inspect for broken or damaged pins. If broken or

damaged pins are found, replace before using.

Use of broken pins may result in detachment or

deformation of the attachment, causing loss of

performance, personal injury, or death.

You are now ready to use the attached attachment.

Attach and remove all compatible attachments using

the same method.

WARNING

To avoid personal injury, death, or machine damage

• Never operate or transport the attachments

which are not attached properly.

• Always replace damaged hardware immediately.

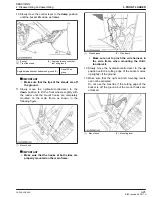

4.2.2 Detaching attachments

Detach the attachments in the reverse procedure of

attaching the attachments.

1. Lower the attachment to ground level with the

attachment slightly in the rolled back position.

2. Stop the engine and set the parking brake.

3. Pull the quick-attach-coupler-handles to the

unlatched position to release the latching pins.

4. While sitting in the operator's seat of the tractor,

start the engine and slowly move the loader-control-

lever to the dump position until the attachment is

pushed away slightly from the quick-attach-coupler.

5. Lower the boom of the loader so that the quick-

attach-coupler-mounting-plate

clears

the

attachment saddle.

6. Back away from the attachment slowly.

7. If an attachment is not going to be attached to the

quick-attach-coupler immediately, push the quick-

attach-coupler-handles to the locked position to

prevent damage to the handle assembly.

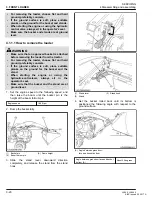

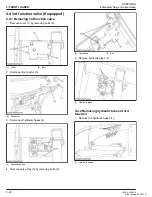

4.2.3 Removing bucket cylinder

CAUTION

To avoid personal injury:

• Before you disconnect hydraulic hoses, be sure

to release all pressure.

1. Disconnect the hydraulic hoses from the bucket

cylinder.

2. Remove lower pin and upper pin and remove the

bucket cylinder (1).

(1) Bucket cylinder

(When reassembling)

• To install the bucket cylinder (1), the hydraulic port

must point inside and be careful of the direction of

grease fittings.

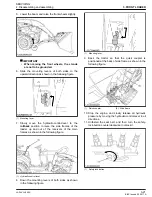

4.2.4 Removing boom cylinder and

hydraulic tubes

1. Disconnect the hydraulic hoses from the boom

cylinders (4).

2. Remove the pins (2) and remove the boom

cylinders (4).

3. Disconnect the hydraulic hoses (6) with quick

couplers at the control valve.

4. Remove the pins (1) and remove the boom (3) from

the side frame (5).

3. FRONT LOADER

SERVICING

4.Disassembling and assembling

3-28

LA344, LA344S

KiSC issued 02, 2017 A

Summary of Contents for LA344

Page 1: ...LA344 LA344S WORKSHOP MANUAL FRONT LOADER KiSC issued 02 2017 A ...

Page 5: ...1 INFORMATION KiSC issued 02 2017 A ...

Page 9: ...1 INFORMATION SAFETY FIRST 1 4 LA344 LA344S KiSC issued 02 2017 A ...

Page 11: ...1 INFORMATION SAFETY DECALS 1 6 LA344 LA344S KiSC issued 02 2017 A ...

Page 12: ...SAFETY DECALS 1 INFORMATION LA344 LA344S 1 7 KiSC issued 02 2017 A ...

Page 15: ...1 INFORMATION TERMINOLOGY 1 10 LA344 LA344S KiSC issued 02 2017 A ...

Page 20: ...2 GENERAL KiSC issued 02 2017 A ...

Page 22: ...2 GENERAL IDENTIFICATION 2 2 LA344 LA344S KiSC issued 02 2017 A ...

Page 24: ...2 GENERAL 2 4 LA344 LA344S KiSC issued 02 2017 A ...

Page 26: ...2 GENERAL LUBRICATING SYSTEM 2 6 LA344 LA344S KiSC issued 02 2017 A ...

Page 30: ...2 GENERAL TIGHTENING TORQUES 5 Hydraulic fittings 2 10 LA344 LA344S KiSC issued 02 2017 A ...

Page 32: ...2 GENERAL MAINTENANCE CHECK LIST 2 12 LA344 LA344S KiSC issued 02 2017 A ...

Page 36: ...2 GENERAL SPECIAL TOOLS 1 Special tools for loader 2 16 LA344 LA344S KiSC issued 02 2017 A ...

Page 37: ...3 FRONT LOADER KiSC issued 02 2017 A ...

Page 71: ...3 FRONT LOADER SERVICING 5 Servicing 3 34 LA344 LA344S KiSC issued 02 2017 A ...