GENERAL

LA525, LA765, WSM

G-10

[3] CHECK POINT OF INITIAL 20 TO 30 HOURS

Re-tightening of Hardware

After 20 to 30 hours of initial loader operation, re-tighten all

mounting bolts and nuts to the required torque value as follows.

9Y1211014GEG0009US0

[4] CHECK POINT OF EVERY 50 HOURS

Checking Main Frame Mounting Bolts (LA525)

CAUTION

To avoid personal injury:

• Never operate front loader with a loose main frame.

• Any time bolts are loosened, retighten to specified torque.

• Check all bolts frequently and keep them tight.

1. Check main frame bolts and nuts regularly especially when

new. If they are loose, tighten them as follows.

9Y1211014GEG0010US0

Tightening torque

Main frame bolts (M16)

226 N·m

23.0 kgf·m

166 lbf·ft

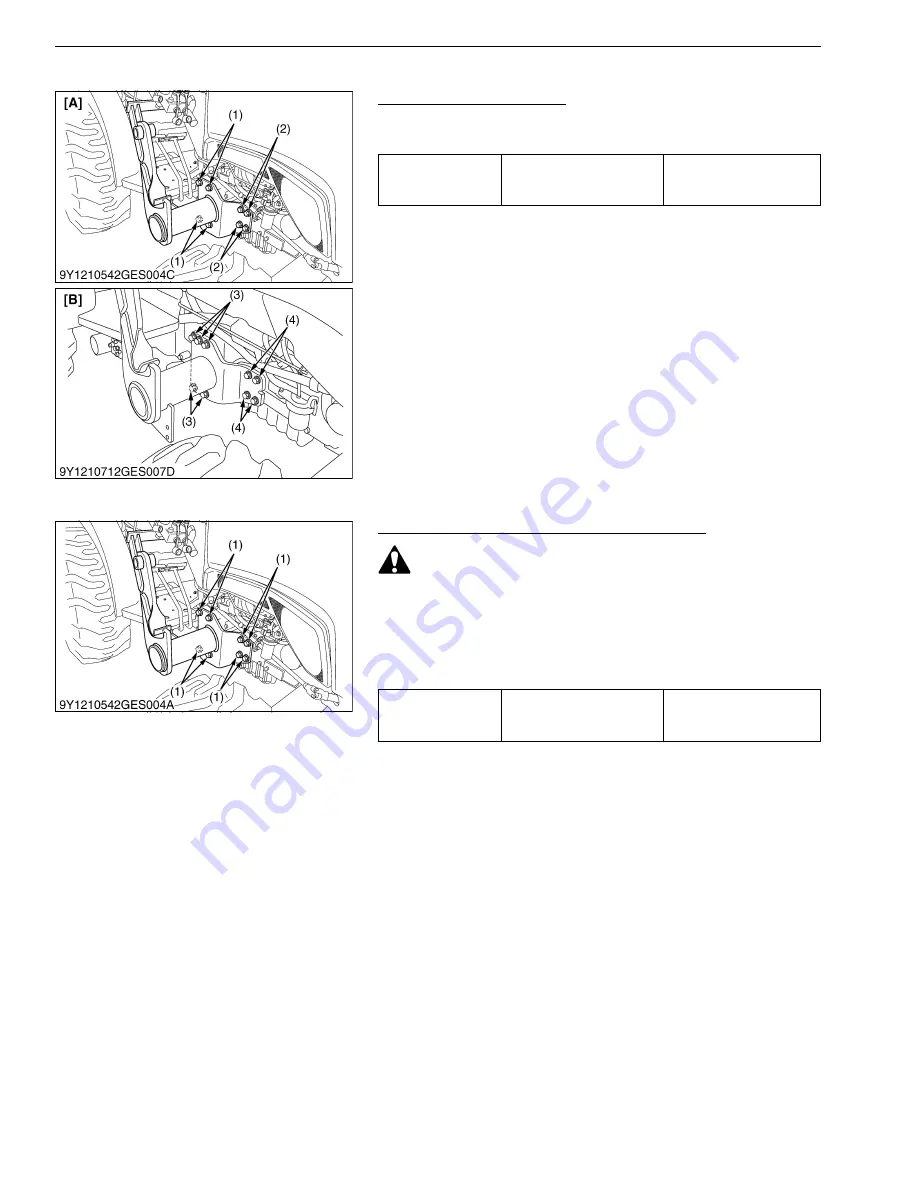

(1) 18-M16 × 40 Bolt

8-M16 Spring Lock Washer

8-5/8 Hardened Plain Washers

(2) 8-M16 × 40 Bolt

8-M16 Spring Lock Washer

(3) 10-M16 × 45 Bolt

10-M16 Spring Lock Washer

10-5/8 Hardened Plain Washer

(4) 8-M16 × 45 Bolt

8-M16 Spring Lock Washer

[A] LA525

[B] LA765

Tightening torque

Main frame mounting bolt

226 N·m

23.0 kgf·m

166 lbf·ft

(1) Main Frame Mounting Bolt

KiSC issued 06, 2017 A

Summary of Contents for LA525

Page 1: ...LA525 LA765 WORKSHOP MANUAL FRONT LOADER KiSC issued 06 2017 A ...

Page 4: ...I INFORMATION KiSC issued 06 2017 A ...

Page 10: ...INFORMATION LA525 LA765 WSM I 5 9Y1211014INI0001US0 KiSC issued 06 2017 A ...

Page 11: ...INFORMATION LA525 LA765 WSM I 6 9Y1211014INI0002US0 KiSC issued 06 2017 A ...

Page 20: ...G GENERAL KiSC issued 06 2017 A ...