85

TIRES, WHEELS AND BALLAST

WHEEL ADJUSTMENT

To avoid personal injury:

A

When working on slopes or when working with

trailer, set the wheel tread as wide as practical

for maximum stability.

A

Support tractor securely on stands before

removing a wheel.

A

Do not work under any hydraulically supported

devices. They can settle, suddenly leak down,

or be accidentally lowered. If necessary to work

under tractor or any machine elements for

servicing or adjustment, securely support them

with stands or suitable blocking beforehand.

A

Never operate tractor with a loose rim, wheel,

or axle.

B

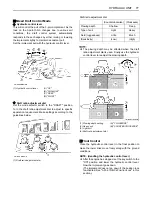

Front Wheels (with four wheel drive)

Front tread width can be adjusted as shown with the

standard equipped tires.

To change the tread width

1. Remove the wheel rim and disk mounting bolts.

2. Change the position of the rim and tire to the desired

position, and tighten the bolts.

3. Adjust the toe-in [2 to 8mm]

See "Adjusting Toe-in" in "EVERY 200 HOURS" in

"PERIODIC SERVICE" section.

A

Need to limit turning angle depended on the tire size

and tread.

A

Always attach wheels as shown in the drawing.

A

If not attached as illustrated, transmission parts may

be damaged.

A

When re-fitting or adjusting a wheel, tighten the bolts

to the following torques then recheck after driving the

tractor 200m (200 yards) and 10 times of shuttle

movement by 5 m (5 yards), and thereafter according

to service interval. (See "MAINTENANCE" section.)

A

Wheels with beveled or tapered holes: Use the

tapered side of lug nut.

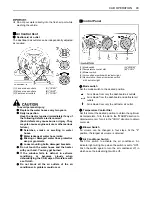

To avoid personal injury:

A

Before jacking up the tractor, park it on a firm

and level ground and chock the rear wheels.

A

Fix the front axle to keep it from swinging.

A

Select jacks that withstand the machine weight

and set them up as shown below.

(1) 260 to 304 N-m (26.5 to 31 kgf-m)

(1) Jack point

Summary of Contents for M100GX

Page 17: ... 7 SAFE OPERATION 7 DANGER WARNING AND CAUTION LABELS ...

Page 18: ...SAFE OPERATION 8 ...

Page 19: ... 9 SAFE OPERATION ...

Page 20: ...SAFE OPERATION 10 ...

Page 21: ... 11 SAFE OPERATION ...