Summary of Contents for M96SDTM

Page 10: ......

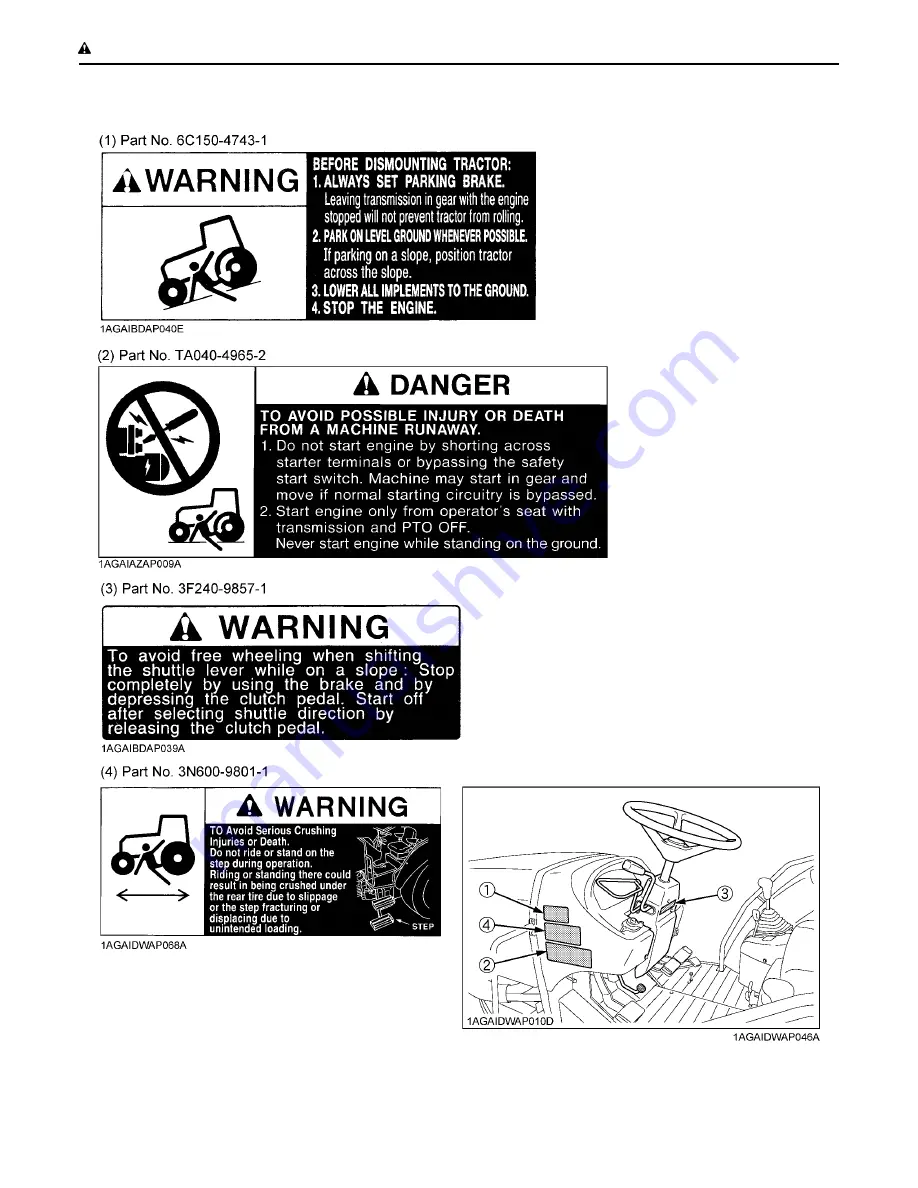

Page 17: ... 7 SAFE OPERATION 7 DANGER WARNING AND CAUTION LABELS ...

Page 18: ...SAFE OPERATION 8 ...

Page 19: ... 9 SAFE OPERATION ...

Page 20: ...SAFE OPERATION 10 ...

Page 21: ... 11 SAFE OPERATION ...

Page 121: ...M96SDTM MUDDER TRACTOR M96SDTM ...

Page 124: ......