PERIODIC SERVICE

72

B

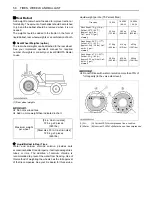

Checking Wheel Bolt Torque

To avoid personal injury:

A

Never operate tractor with a loose rim, wheel,

or axle.

A

Any time bolts and nuts are loosened, retighten

to specified torque.

A

Check all bolts and nuts frequently and keep

them tight.

Check wheel bolts and nuts regularly especially when

new. If they are loose, tighten them as follows.

EVERY 100 HOURS

B

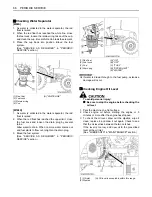

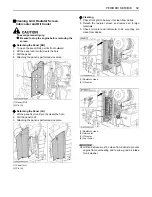

Lubricating Grease Fittings

Apply a small amount of multipurpose grease to the

following points every 100 hours:

If you operated the machine in extremely wet and muddy

conditions, lubricate grease fittings more often.

N-m (kgf-m) [ft-lbs.]

(1)

(2)

(3)

(4)

2WD

168 to 196

(17.1 to 20.0)

[124 to 145]

---

Steel disc

244 (24.9)

[180]

Cast iron disc

260 to 304

(26.5 to 31.0)

[192 to 224]

343 to 401

(35.0 to 41.0)

[254 to 297]

4WD

260 to 304

(26.5 to 31.0)

[192 to 224]

Waffle wheel

298 to 366

(30.4 to 37.3)

[220 to 270]

Except waffle

wheel

244 (24.9)

[180]

(1) Grease fitting (Knuckle shaft) [RH, LH]

(1) Grease fitting (Front axle support)

(1) Grease fitting (Front axle support)

Summary of Contents for M96SDTM

Page 10: ......

Page 17: ... 7 SAFE OPERATION 7 DANGER WARNING AND CAUTION LABELS ...

Page 18: ...SAFE OPERATION 8 ...

Page 19: ... 9 SAFE OPERATION ...

Page 20: ...SAFE OPERATION 10 ...

Page 21: ... 11 SAFE OPERATION ...

Page 121: ...M96SDTM MUDDER TRACTOR M96SDTM ...

Page 124: ......