18

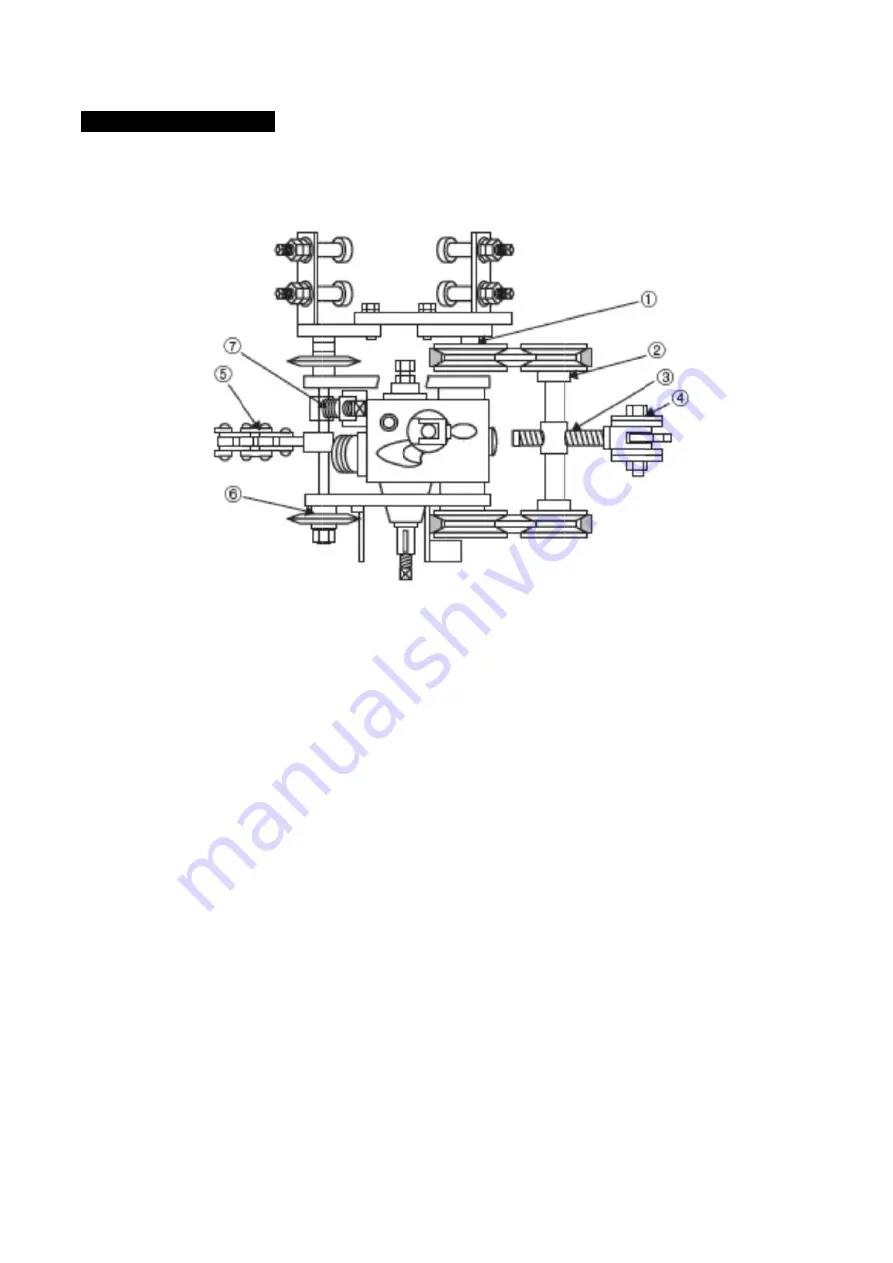

Fig.14

Oiling points

Section 4 Maintenance

Maintenance is very important to keep the Keel Cutter in good co ndition all the time. Clean off dust

and stain. After rinsing entire dirt, Oil the frictional and sliding areas shown in the figure below.

1 Wheel

1. Leaving rusty matter on the wheel loses durability. Make sure to rinse the wheel after use.

2. Make sure a diamond chipped wheel is not cracked or damaged in any other way.

3. The Grooving Wheel needs to be sharped every 40 feet of grooving length as a guide line. Ask the

stores for sharpening the wheel.

2 Machine Body Gear case

Check the amount of oil. Keep the machine level to check the amount of oil. Oil level is good if the

oil is visible on the oil checking window.

3 Roller Chain

Make sure to clean off dust and stain after use. Oil the chains to keep the Roller Chain in smooth

movement. (

⑤

of Fig.14)

4 V - Belt

1. Leaving rusty matter on the V-Belt (particularly on the wheel side) loses durability.

to remove any rusty matter after use.

2. Runs of cords are a sign of replacing the belt.

Make sure