30

OPERATION OF THE MACHINE

OPERATION OF THE MACHINE

To avoid personal injury or death:

A

The safety instructions (page

-) must be

followed.

A

The wheel loader may only be operated

according to its approved use (page

-).

A

The wheel loader may only be operated by

trained personnel (page

-).

GUIDING THE OPERATOR

A

If the operator's working and driving area is obscured,

the operator must be supported by a guide.

A

The guide must be capable of performing this kind of

work.

A

Before starting work, the guide and the operator must

agree the necessary signals.

A

The guide's position must be clearly visible by the

operator.

A

The operator must stop the wheel loader immediately

if the eye contact to the guide is interrupted.

As a rule, either the wheel loader or the guide may

move, never both at once!

WORKING IN THE VICINITY OF

OVERHEAD POWER LINES

When working with the wheel loader in the vicinity of

overhead power lines and tram lines, a minimum distance

as specified in the following table must be maintained

between the wheel loader and its attachments and the

power line.

If safe distances can not be maintained, the power lines

must be switched off in coordination with their owner or

provider and secured against making them live again.

When approaching overhead power lines, any possible

movements of the wheel loader must be taken into

consideration.

Unevenness of the ground or sloping the wheel loader can

reduce the safe distance.

Wind can cause the overhead power lines to sway, thus

reducing the safe distance.

In case of a power cross-over, leave the danger zone with

the wheel loader, if possible, by taking suitable measures.

If this is not possible, do not leave the operator's place,

warn any approaching persons of the danger, and have

the power switched off.

RUNNING-IN OF THE MACHINE

The operation and care of the new machine influences its

life span. Your new machine has been carefully checked

and tested before leaving the factory. In spite of this, all

movable components must run-in during the first 50 work

hours. Do not work with full rpm's and full loads during this

period. It is most important to run-in your machine

properly in order to achieve its full performance and

longevity. During the running-in, the following points

should be adhered to in all cases.

B

Do not Work with Full Engine Rpm's or

Full Loads during the First 50 Working

Hours

A

Let the engine warm up sufficiently in the cold season.

A

Do not let the engine rev-up more than necessary.

B

Oil Change in the Run-in Stage

The lubrication oil plays a specific and important role

during the run-in phase of the machine. The numerous

movable parts are not yet run-in, so many fine metal

particles can be generated and may cause damage and

shorten the life of many components. Pay attention to the

oil-change intervals and complete them sooner than later.

See "MAINTENANCE INTERVALS" in "MAINTENANCE"

section for more details on the oil-change intervals.

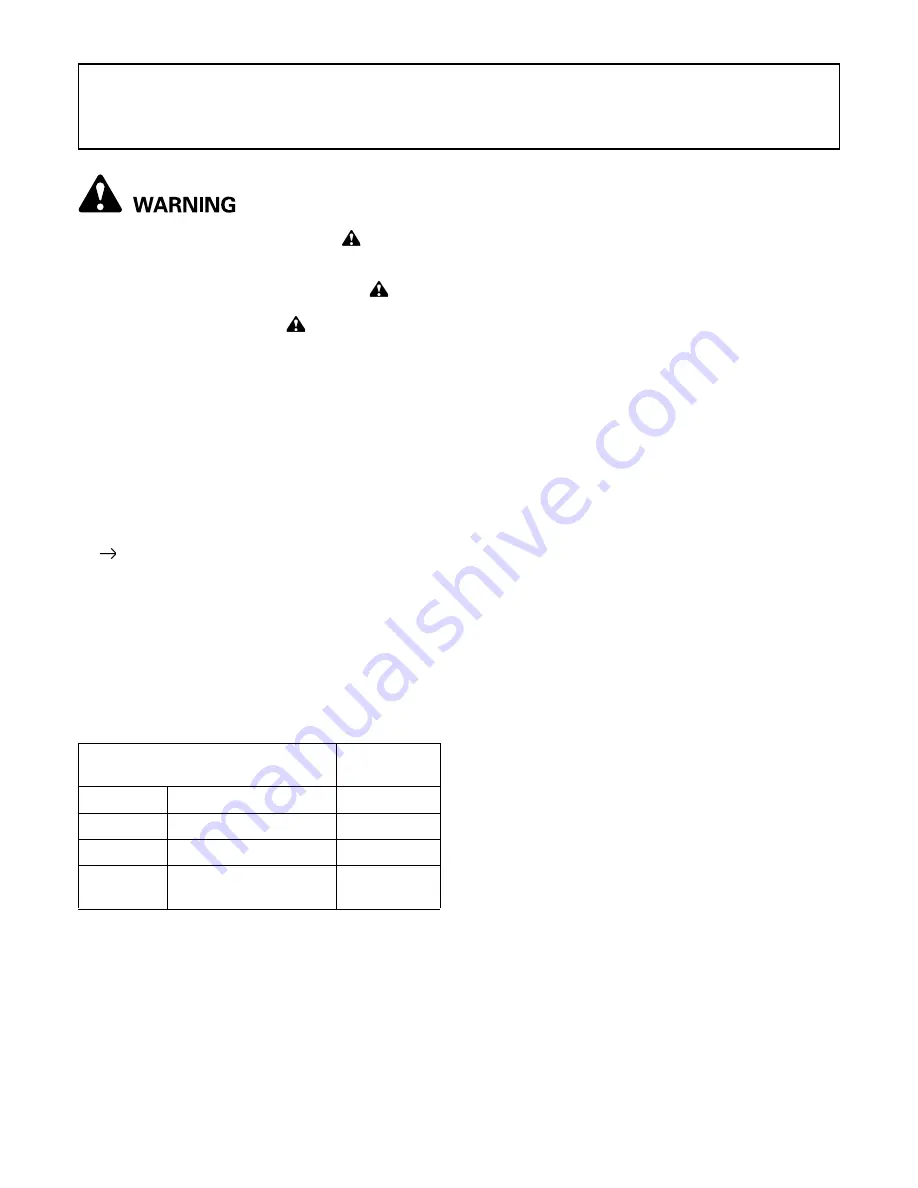

Rated voltage [V]

Safe distance

[m]

up to 1 kV

1.0

over 1 kV

up to 110 kV

3.0

over 110 kV

up to 220 kV

4.0

over 220 kV

up to 380 kV or when

rated voltage is unknown

5.0

Summary of Contents for R065

Page 9: ...CONTENTS SERVICE HOUR METER 89 ...

Page 10: ......

Page 22: ...SAFE OPERATION 12 8 DANGER AND WARNING LABELS ...

Page 23: ... 13 SAFE OPERATION ...

Page 24: ...SAFE OPERATION 14 ...

Page 25: ... 15 SAFE OPERATION ...

Page 26: ...SAFE OPERATION 16 ...

Page 28: ......

Page 30: ...SERVICING OF WHEEL LOADER 2 1 Engine serial No ...