PERIODIC SERVICE

62

B

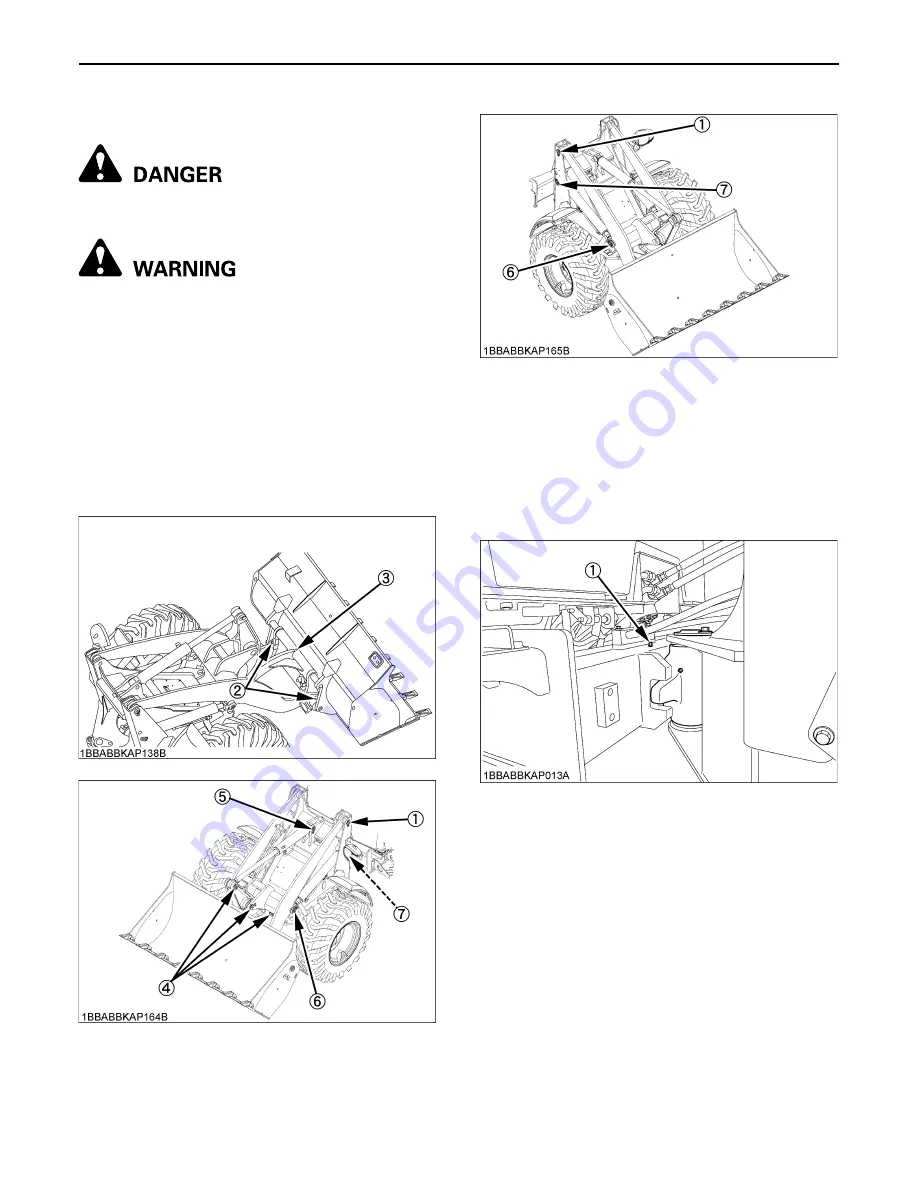

Grease fittings

To avoid serious personal injury or death:

A

Keep clear of articulation joint during service

work.

To avoid personal injury or death:

A

Before greasing, always stop the engine, lower

the bucket and attachment to the ground,

release the hydraulic pressure in the hydraulic

system by operating the control levers, lock all

control levers in neutral, and remove the key.

A

Always remove the bucket and attachment and

use the lift arm support when servicing the

machine with the loader lift arms raised.

C

Greasing the front attachments

Apply grease to the fittings on the front attachments

indicated by the arrows in the illustration.

C

Greasing the rear frame

Apply grease to the rear frame at one grease fitting.

(1) Lift arm attachment pin (2 places)

(2) Quick coupler pin (2 places)

(3) Bucket link pin (1 place)

(4) Bell crank arm pin (3 places)

(5) Bucket cylinder bottom pin (1 place)

(6) Lift cylinder rod pin (2 places)

(7) Lift cylinder bottom pin (2 places)

(1) Grease fitting

Summary of Contents for R065

Page 9: ...CONTENTS SERVICE HOUR METER 89 ...

Page 10: ......

Page 22: ...SAFE OPERATION 12 8 DANGER AND WARNING LABELS ...

Page 23: ... 13 SAFE OPERATION ...

Page 24: ...SAFE OPERATION 14 ...

Page 25: ... 15 SAFE OPERATION ...

Page 26: ...SAFE OPERATION 16 ...

Page 28: ......

Page 30: ...SERVICING OF WHEEL LOADER 2 1 Engine serial No ...