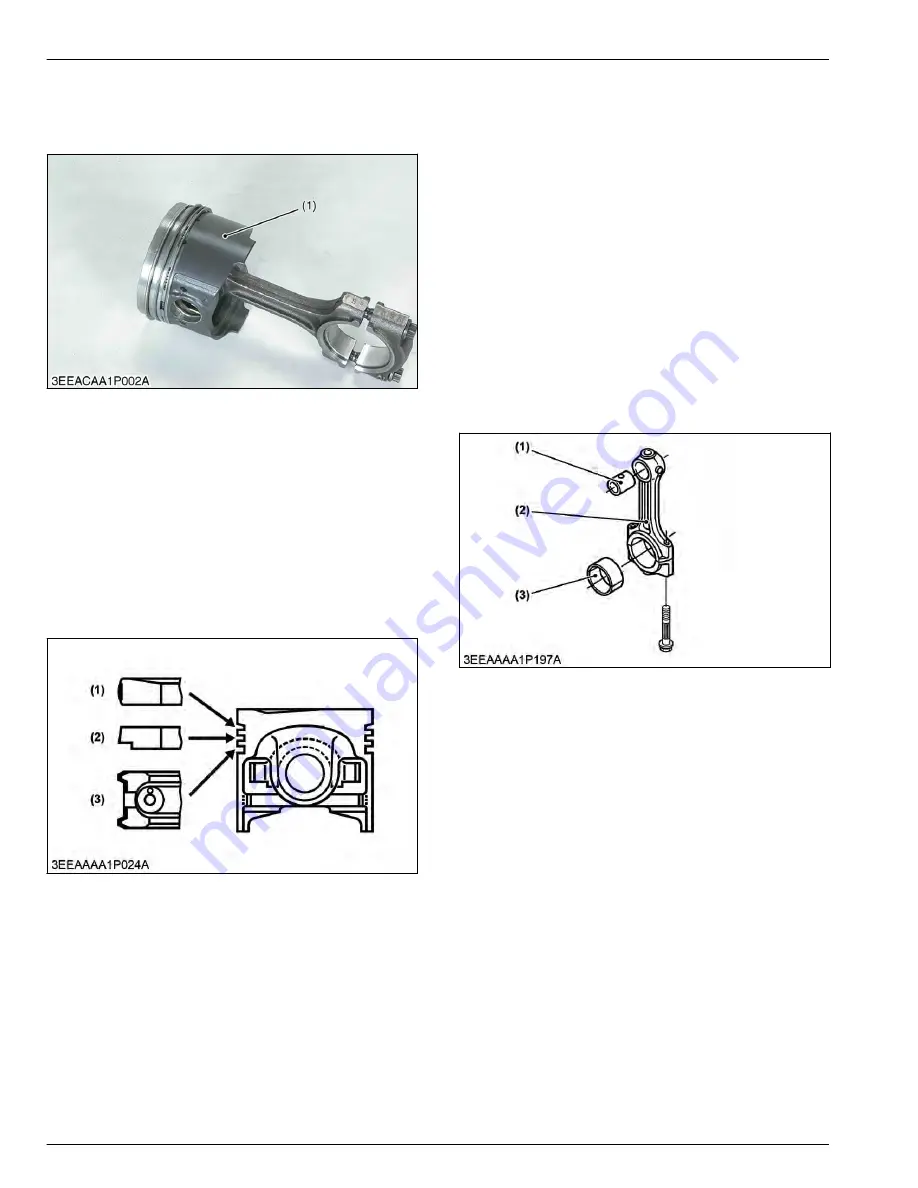

1.4 Function of piston

The piston creates the forces for the suction,

compression, power and exhaust cycles.

(1) Molybdenum disulfide

The reciprocating motion of a piston in the engine

cylinder creates the forces for the suction,

compression, power and exhaust cycles. The piston's

skirt is coated with molybdenum disulfide (MoS

2

) which

reduces the piston slap noise and thus the entire

operating noise. The molybdenum disulfide (MoS

2

) (1)

improves the fit of the piston with the cylinder and helps

to prevent scorching. This material helps resist metal

wears even with little lube oil.

1.5 Function of piston ring

(1) Top compression ring

(2) Second compression ring

(3) Oil control ring

Piston rings are classified as compression and oil

control rings. Diesel engine has two or three

compression rings around the piston head and one oil

ring just below them. The compression rings prevent

gases from leaking by the piston during the

compression and expansion strokes. They seal by

expanding out against the cylinder wall. The rings

expand by their own tension and also by combustion

pressure behind the rings during the expansion stroke.

The compression rings are split for easy assembly on

the piston. The piston rings are usually made of

hardened cast iron. To reduce the wear on the ring,

they are often plated with chrome on their contact

faces, or are coated their contact faces with

molybdenum disulfide.

• The top compression ring (1) is a keystone type

ring to get durability against heavy load.

• The second compression ring (2) is an undercut

ring to prevent shortage of oil.

• The main job of the oil control ring (3) is to wipe the

excess oil from the cylinder walls. This oil is fed

through slots in the rings to holes in the piston

groove, where it returns to the crankcase. For

better oil control, spring expanders are often used

under the oil control ring.

1.6 Function of connecting rod

The connecting rod connects the piston to the

crankshaft.

(1) Small end bushing

(2) Connecting rod

(3) Crankpin bushing

The connecting rod must be light and yet strong

enough to transmit the thrust of the piston to

crankshaft. The big end of connecting rod has a

crankpin bushing (3) (split type) and the small end has

a small end bushing (1) (solid type).

1.7 Function of crankshaft

The crankshaft converts the up-and-down motion of the

pistons into rotary motion. It ties together the reactions

3. ENGINE

MECHANISM

1. Engine body

3-2

BX1880,BX2380,BX2680,RCK60B-23BX,RCK54-23BX,RCK48-18BX,RCK60D-26BX,RCK54D-26BX

KiSC issued 03, 2019 A

Summary of Contents for ,RCK60B-23BX

Page 19: ...1 INFORMATION KiSC issued 03 2019 A ...

Page 42: ...2 GENERAL KiSC issued 03 2019 A ...

Page 111: ...3 ENGINE KiSC issued 03 2019 A ...

Page 190: ...4 TRANSAXLE KiSC issued 03 2019 A ...

Page 255: ...5 FRONT AXLE KiSC issued 03 2019 A ...

Page 274: ...6 STEERING KiSC issued 03 2019 A ...

Page 291: ...7 HYDRAULIC SYSTEM KiSC issued 03 2019 A ...

Page 344: ...8 ELECTRICAL SYSTEM KiSC issued 03 2019 A ...

Page 399: ...9 MOWER KiSC issued 03 2019 A ...