• Apply clean engine oil on the bearings.

• Install the main bearing case assemblies in the

original positions.

Since diameters of main bearing cases vary, install

them in order of markings (b) (

[A]

,

[B]

,

[C]

) from

the gear case side.

• Match the alignment numbers (a) on the main

bearing case assembly 1.

• When installing the main bearing case 1 and 2, face

the mark

[FLYWHEEL]

to the flywheel.

• Install the thrust bearing (3) with its oil groove

facing outward.

• Make sure that the main bearing case moves

smoothly after tightening the main bearing case

screw 1 to the specified torque.

BX1880 and BX2380

Tightening tor-

que

Main bearing case

screw 1

13 to 15 N

⋅

m

1.4 to 1.5 kgf

⋅

m

9.6 to 11 lbf

⋅

ft

BX2680

Tightening tor-

que

Main bearing case

screw 1

30 to 34 N

⋅

m

3.1 to 3.4 kgf

⋅

m

23 to 25 lbf

⋅

ft

6. Servicing

6.1 Cylinder head and valve

6.1.1 Checking top clearance

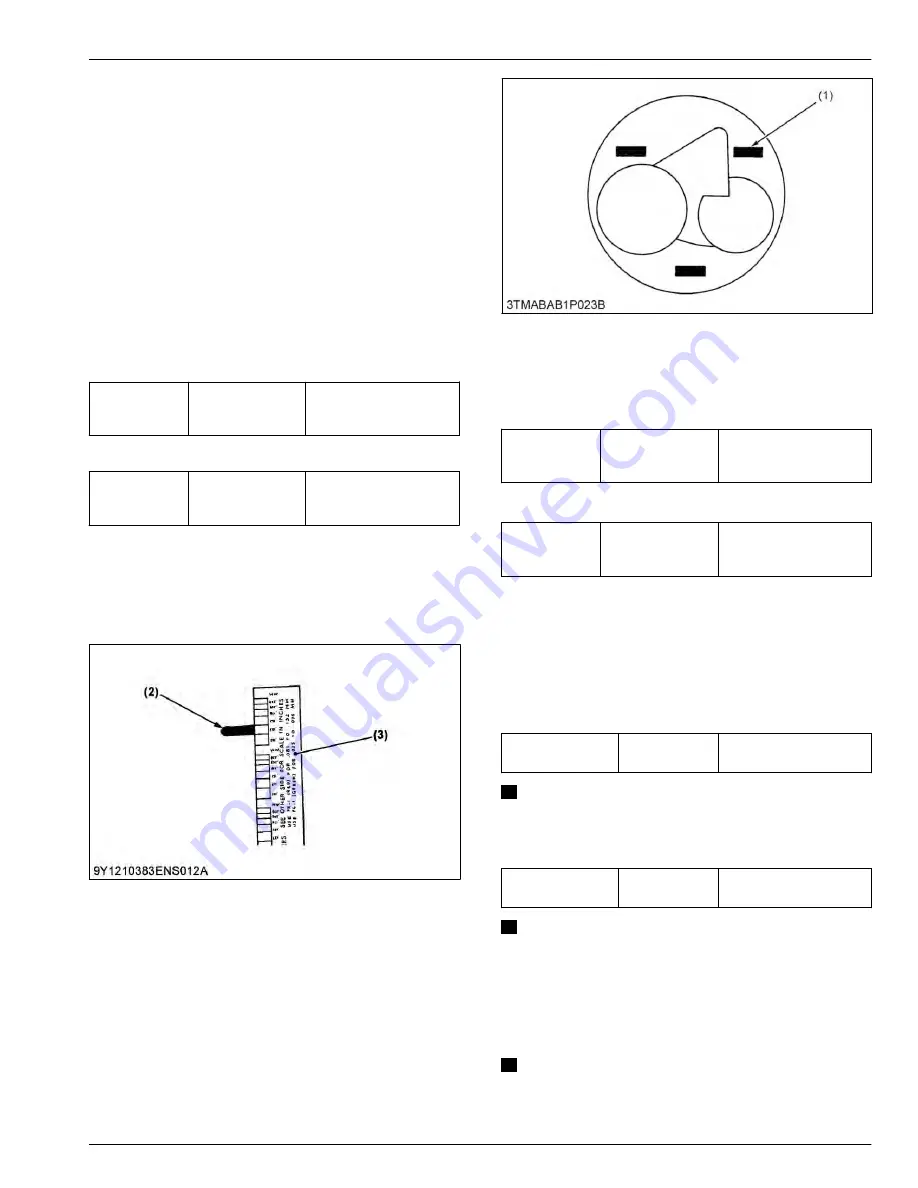

(2) Crushed plastigauge

(3) Scale

1. Remove the cylinder head.

2. With the piston at T.D.C., use grease to affix three

or four plastigauges (1) of a diameter 1.5 mm

(0.059 in.) × 5.0 to 7.0 mm (0.20 to 0.27 in.) long to

the crown of the piston; keep the gauges away from

the intake valve and combustion chamber fittings.

(1) Plastigauge

3. Take the piston to an intermediate position, install

the cylinder head and tighten the head bolts to the

specified torque.

BX1880 and BX2380

Tightening tor-

que

Cylinder head

screw

38 to 42 N

⋅

m

3.9 to 4.2 kgf

⋅

m

28 to 30 lbf

⋅

ft

BX2680

Tightening tor-

que

Cylinder head

screw

64 to 68 N

⋅

m

6.6 to 6.9 kgf

⋅

m

48 to 50 lbf

⋅

ft

4. Turn the crankshaft so the piston goes through

T.D.C.

5. Remove the cylinder head and compare the width

of the crushed plastigauges (2) with the scale.

6. If they are out of specification, check the oil

clearance of the crank pin, journals and piston pins.

BX1880 and BX2380

Top clearance

Factory specifi-

cation

0.55 to 0.70 mm

0.022 to 0.028 in.

NOTE

•

Top clearance = Width of the crushed plastigauge (2).

BX2680

Top clearance

Factory specifi-

cation

0.55 to 0.75 mm

0.022 to 0.030 in.

NOTE

•

Top clearance = Width of the crushed plastigauge (2).

6.1.2 Checking cylinder head surface

flatness

IMPORTANT

• Do not place the straightedge on the

combustion chamber.

SERVICING

6. Servicing

3. ENGINE

BX1880,BX2380,BX2680,RCK60B-23BX,RCK54-23BX,RCK48-18BX,RCK60D-26BX,RCK54D-26BX

3-55

KiSC issued 03, 2019 A

Summary of Contents for ,RCK60B-23BX

Page 19: ...1 INFORMATION KiSC issued 03 2019 A ...

Page 42: ...2 GENERAL KiSC issued 03 2019 A ...

Page 111: ...3 ENGINE KiSC issued 03 2019 A ...

Page 190: ...4 TRANSAXLE KiSC issued 03 2019 A ...

Page 255: ...5 FRONT AXLE KiSC issued 03 2019 A ...

Page 274: ...6 STEERING KiSC issued 03 2019 A ...

Page 291: ...7 HYDRAULIC SYSTEM KiSC issued 03 2019 A ...

Page 344: ...8 ELECTRICAL SYSTEM KiSC issued 03 2019 A ...

Page 399: ...9 MOWER KiSC issued 03 2019 A ...