• Be sure to check the valve recessing after

correcting.

1. Clean the cylinder head surface.

2. Place a straightedge on the cylinder head's four

sides and two diagonal as shown in the figure.

3. Measure the clearance with a thickness gauge.

4. If the measurement exceeds the allowable limit,

correct it with a surface grinder.

Cylinder head sur-

face flatness

Allowable limit

0.05 mm

0.002 in.

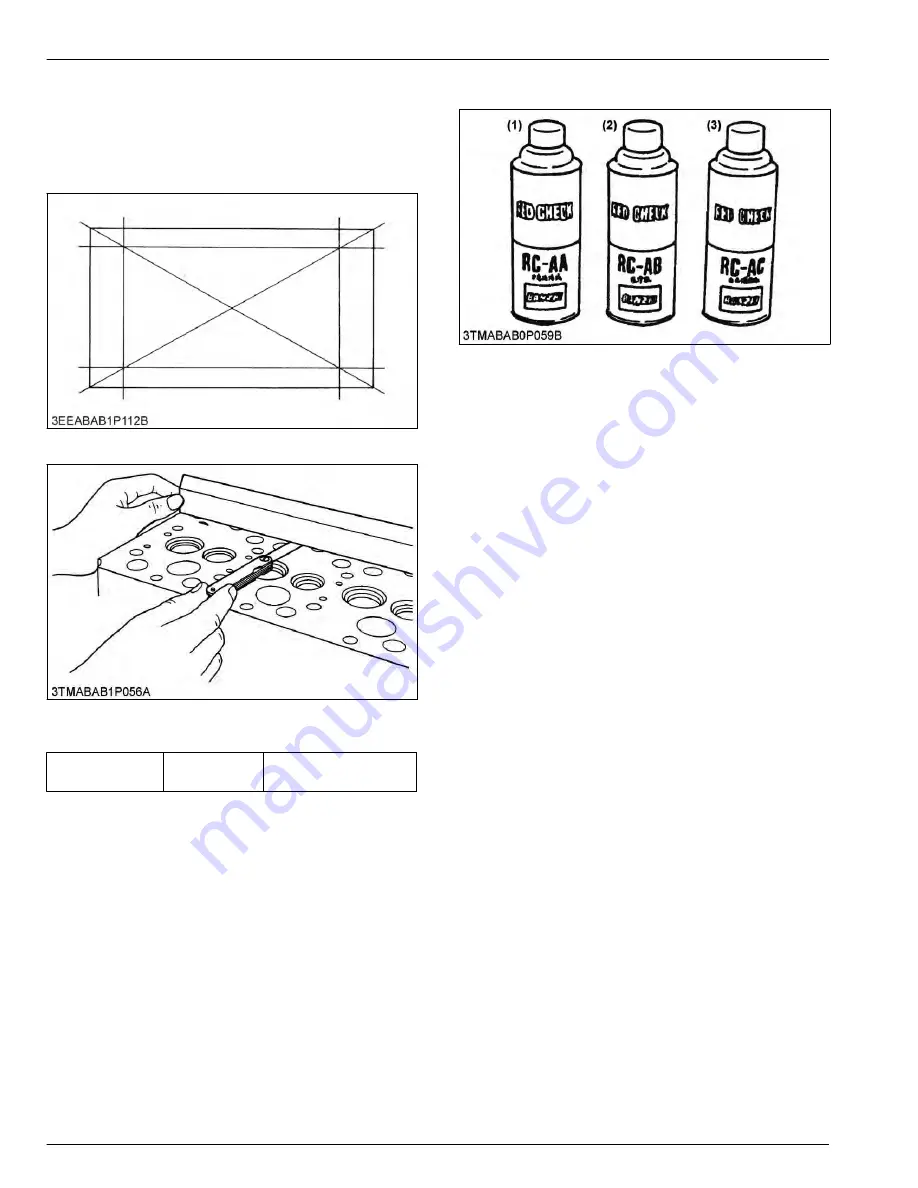

6.1.3 Checking cylinder head flaw

(1) Red permeative liquid

(2) Detergent

(3) White developer

1. Prepare an air spray red check.

2. Clean the surface of the cylinder head with

detergent (2).

3. Spray the cylinder head surface with the red

permeative liquid (1). Leave it five to ten minutes

after spraying.

4. Wash away the red permeative liquid on the

cylinder head surface with the detergent (2).

5. Spray the cylinder head surface with white

developer (3).

6. If flawed, it can be identified as red marks.

3. ENGINE

SERVICING

6. Servicing

3-56

BX1880,BX2380,BX2680,RCK60B-23BX,RCK54-23BX,RCK48-18BX,RCK60D-26BX,RCK54D-26BX

KiSC issued 03, 2019 A

Summary of Contents for ,RCK60B-23BX

Page 19: ...1 INFORMATION KiSC issued 03 2019 A ...

Page 42: ...2 GENERAL KiSC issued 03 2019 A ...

Page 111: ...3 ENGINE KiSC issued 03 2019 A ...

Page 190: ...4 TRANSAXLE KiSC issued 03 2019 A ...

Page 255: ...5 FRONT AXLE KiSC issued 03 2019 A ...

Page 274: ...6 STEERING KiSC issued 03 2019 A ...

Page 291: ...7 HYDRAULIC SYSTEM KiSC issued 03 2019 A ...

Page 344: ...8 ELECTRICAL SYSTEM KiSC issued 03 2019 A ...

Page 399: ...9 MOWER KiSC issued 03 2019 A ...