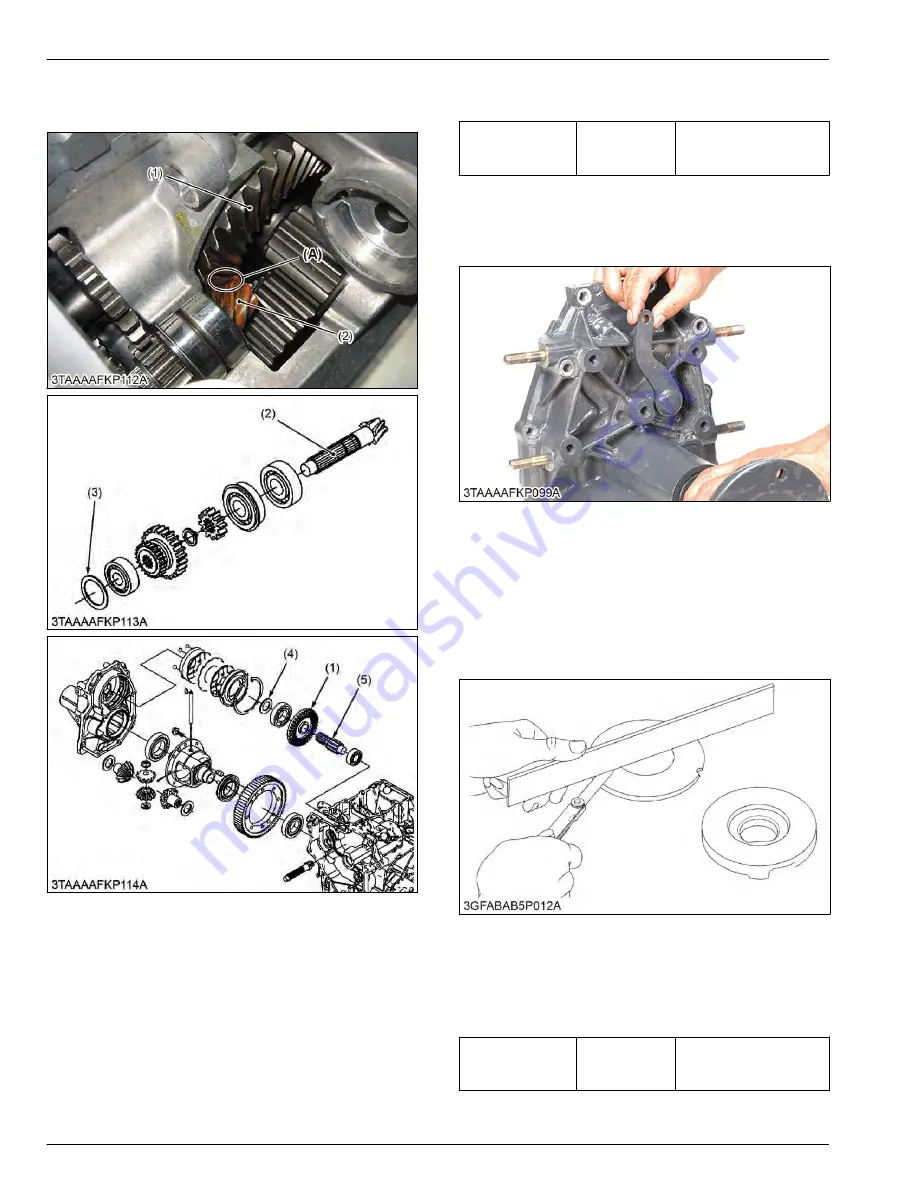

6.2.11 Checking backlash between spiral

bevel pinion gear and bevel gear

(1) Bevel gear

(2) Spiral bevel pinion gear

(3) Shim

(4) Shim

(5) Final gear shaft (Brake shaft)

(A) Bevel gear teeth upper sur-

face

1. Temporarily assemble the spiral bevel pinion gear

(2) and the bevel gear (1) in the transaxle case.

2. Hold the wire of solder or plastigauge on the bevel

gear teeth upper surface (A).

3. Turn the front drive shaft one turn clockwise by

hands.

4. Measure the backlash between the spiral bevel

pinion gear and the bevel gear.

5. If the backlash exceeds the factory specifications,

adjust the shims (3), (4).

Backlash between

spiral bevel pinion

and bevel gear

Factory specifi-

cation

0.10 to 0.30 mm

0.0040 to 0.011 in.

6.2.12 Checking brake cam lever

movement

1. Move the brake cam lever by hand to check its

movement.

2. If its movement is heavy, refine the brake cam with

a emery paper.

6.2.13 Checking flatness of actuator and

bearing holder

1. Place a straightedge on the contacting surface of

the actuator and the bearing holder.

2. Inspect the friction surface of the actuator and the

bearing holder with the straightedge, and determine

if a feeler gauge will fit on the part of wear.

Flatness of actua-

tor and bearing

holder

Allowable limit

0.30 mm

0.012 in.

3. If it will fit, resurface.

4. TRANSAXLE

SERVICING

6. Servicing

4-62

BX1880,BX2380,BX2680,RCK60B-23BX,RCK54-23BX,RCK48-18BX,RCK60D-26BX,RCK54D-26BX

KiSC issued 03, 2019 A

Summary of Contents for ,RCK60B-23BX

Page 19: ...1 INFORMATION KiSC issued 03 2019 A ...

Page 42: ...2 GENERAL KiSC issued 03 2019 A ...

Page 111: ...3 ENGINE KiSC issued 03 2019 A ...

Page 190: ...4 TRANSAXLE KiSC issued 03 2019 A ...

Page 255: ...5 FRONT AXLE KiSC issued 03 2019 A ...

Page 274: ...6 STEERING KiSC issued 03 2019 A ...

Page 291: ...7 HYDRAULIC SYSTEM KiSC issued 03 2019 A ...

Page 344: ...8 ELECTRICAL SYSTEM KiSC issued 03 2019 A ...

Page 399: ...9 MOWER KiSC issued 03 2019 A ...