6.3 Checking backlash between

differential pinion and differential

side gear

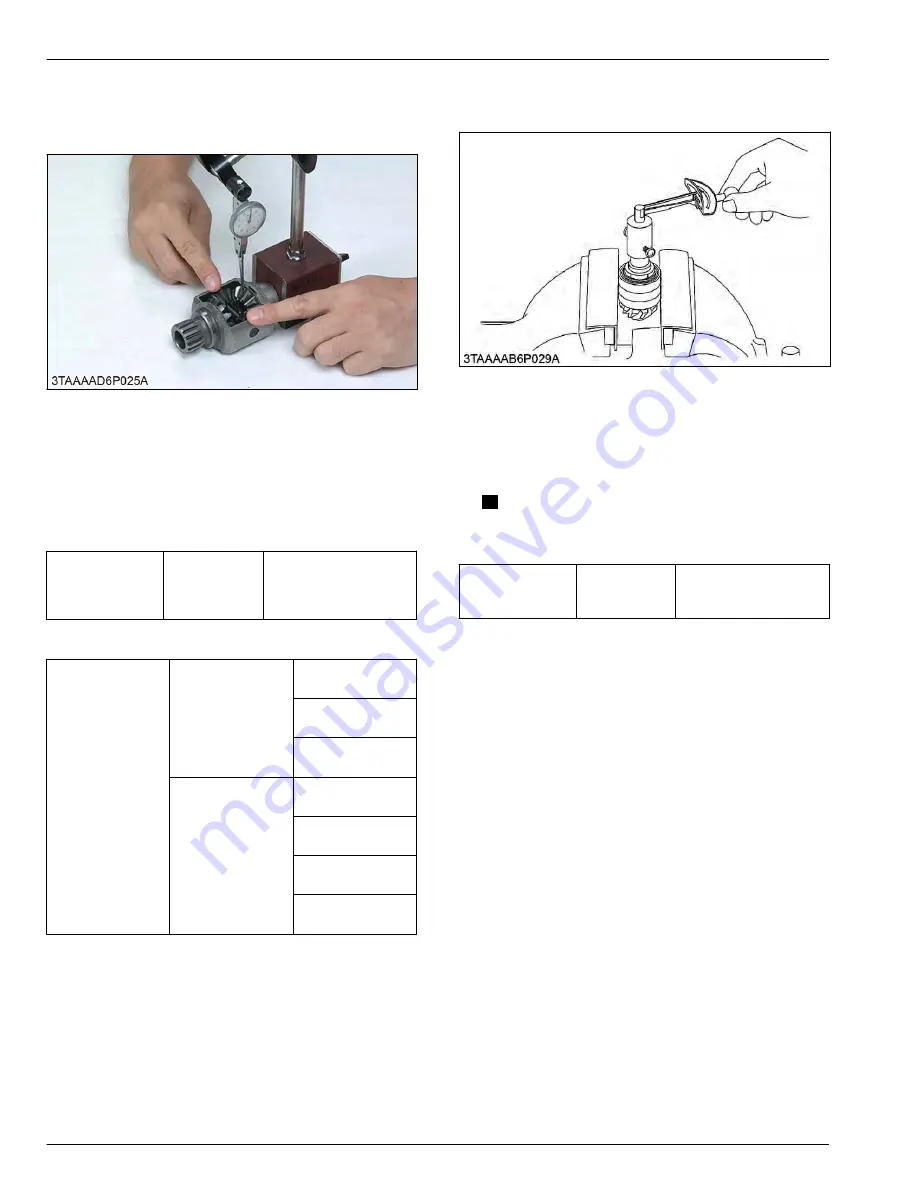

1. Set a dial gauge (lever type) on a tooth of the

differential pinion.

2. Fix the differential side gear, and move the

differential pinion to measure the backlash.

3. If the measurement exceeds the factory

specifications, adjust with the differential side gears

shims.

Backlash between

differential pinion

and differential

side gear

Factory specifi-

cation

0.1 to 0.3 mm

0.004 to 0.01 in.

(Reference)

Thickness of adjust-

ing shims

For side gear

0.80 mm

0.031 in.

1.0 mm

0.039 in.

1.2 mm

0.047 in.

For pinion

3.30 mm

0.130 in.

3.50 mm

0.138 in.

3.70 mm

0.146 in.

3.90 mm

0.154 in.

6.4 Checking turning torque of bevel

pinion shaft

1. Clamp the spiral bevel pinion shaft assembly to the

vise and tighten the staking nut.

2. Measure the turning torque of bevel pinion shaft.

3. If the turning torque is not within the factory

specifications, adjust with the lock nut.

NOTE

• After turning force adjustment, be sure to

stake the lock nut.

Turning torque

Factory specifi-

cation

0.80 to 1.0 N

⋅

m

0.082 to 0.10 kgf

⋅

m

0.59 to 0.73 lbf

⋅

ft

5. FRONT AXLE

SERVICING

6. Servicing

5-16

BX1880,BX2380,BX2680,RCK60B-23BX,RCK54-23BX,RCK48-18BX,RCK60D-26BX,RCK54D-26BX

KiSC issued 03, 2019 A

Summary of Contents for ,RCK60B-23BX

Page 19: ...1 INFORMATION KiSC issued 03 2019 A ...

Page 42: ...2 GENERAL KiSC issued 03 2019 A ...

Page 111: ...3 ENGINE KiSC issued 03 2019 A ...

Page 190: ...4 TRANSAXLE KiSC issued 03 2019 A ...

Page 255: ...5 FRONT AXLE KiSC issued 03 2019 A ...

Page 274: ...6 STEERING KiSC issued 03 2019 A ...

Page 291: ...7 HYDRAULIC SYSTEM KiSC issued 03 2019 A ...

Page 344: ...8 ELECTRICAL SYSTEM KiSC issued 03 2019 A ...

Page 399: ...9 MOWER KiSC issued 03 2019 A ...