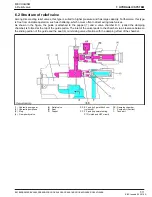

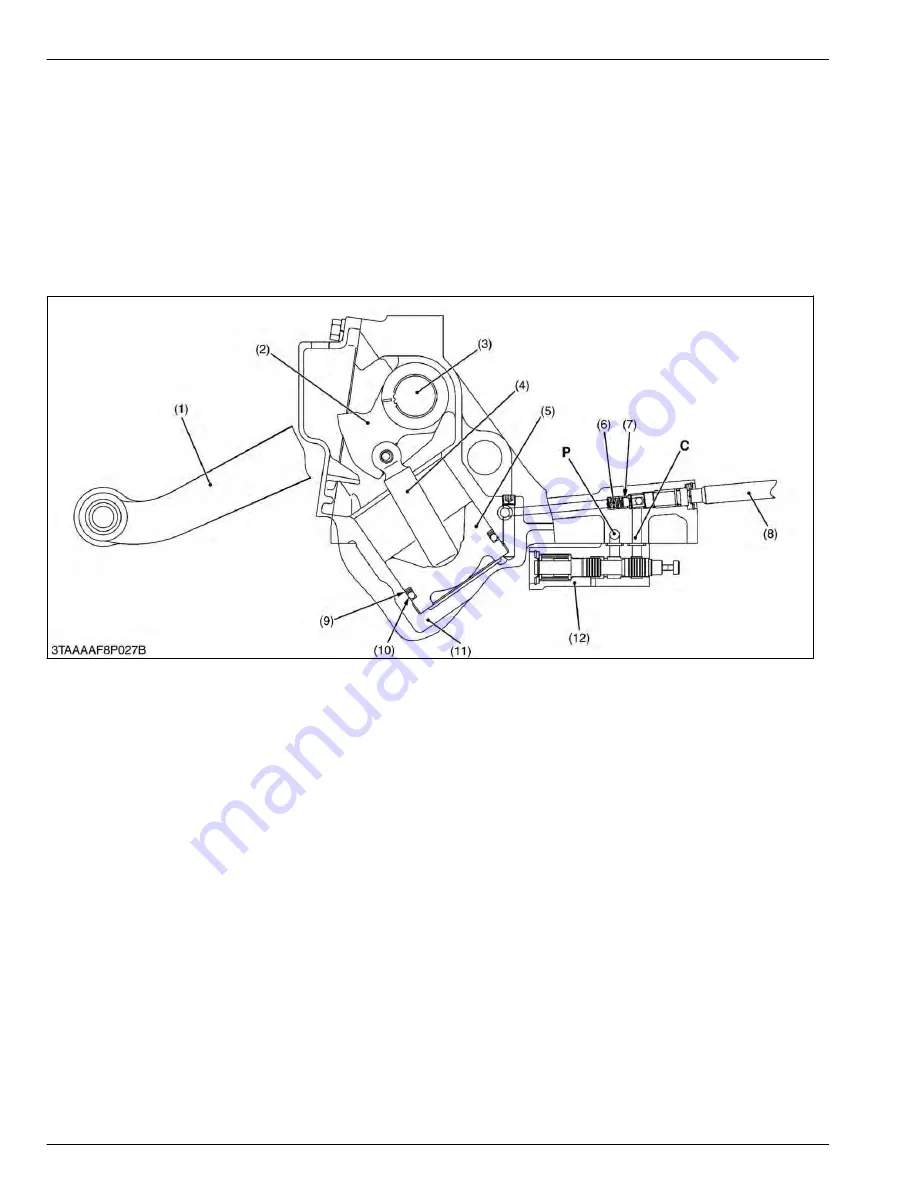

7. Hydraulic cylinder

7.1 Structure of hydraulic cylinder

While the lift arm (1) is rising, oil from the hydraulic pump flows into the hydraulic cylinder through the hydraulic

control valve (12) and cylinder port C. Then oil pushes out the piston (5).

While the lift arm (1) is lowering, oil in the hydraulic cylinder is discharged to the transmission case through the

hydraulic control valve by the weight of the implement. At this time, the lowering speed of the implement can be

controlled by the ball (7) attached to the hydraulic cylinder (11). Turning the lowering speed adjusting knob clockwise

decreases the lowering speed, and counterclockwise increases lowering speed. When the lowering speed adjusting

valve is completely closed, the lift arm (1) is held at its position since oil in the hydraulic cylinder is sealed between the

piston (5) and ball (7).

(1) Lift arm

(2) Hydraulic arm

(3) Hydraulic arm shaft

(4) Hydraulic rod

(5) Piston

(6) Spring

(7) Ball

(8) Lowering speed adjusting

shaft

(9) Back-up ring

(10) O-ring

(11) Hydraulic cylinder

(12) Control valve

P:

Pump port

C:

Cylinder port

7. HYDRAULIC SYSTEM

MECHANISM

7. Hydraulic cylinder

7-14

BX1880,BX2380,BX2680,RCK60B-23BX,RCK54-23BX,RCK48-18BX,RCK60D-26BX,RCK54D-26BX

KiSC issued 03, 2019 A

Summary of Contents for ,RCK60B-23BX

Page 19: ...1 INFORMATION KiSC issued 03 2019 A ...

Page 42: ...2 GENERAL KiSC issued 03 2019 A ...

Page 111: ...3 ENGINE KiSC issued 03 2019 A ...

Page 190: ...4 TRANSAXLE KiSC issued 03 2019 A ...

Page 255: ...5 FRONT AXLE KiSC issued 03 2019 A ...

Page 274: ...6 STEERING KiSC issued 03 2019 A ...

Page 291: ...7 HYDRAULIC SYSTEM KiSC issued 03 2019 A ...

Page 344: ...8 ELECTRICAL SYSTEM KiSC issued 03 2019 A ...

Page 399: ...9 MOWER KiSC issued 03 2019 A ...