(a) Loosen

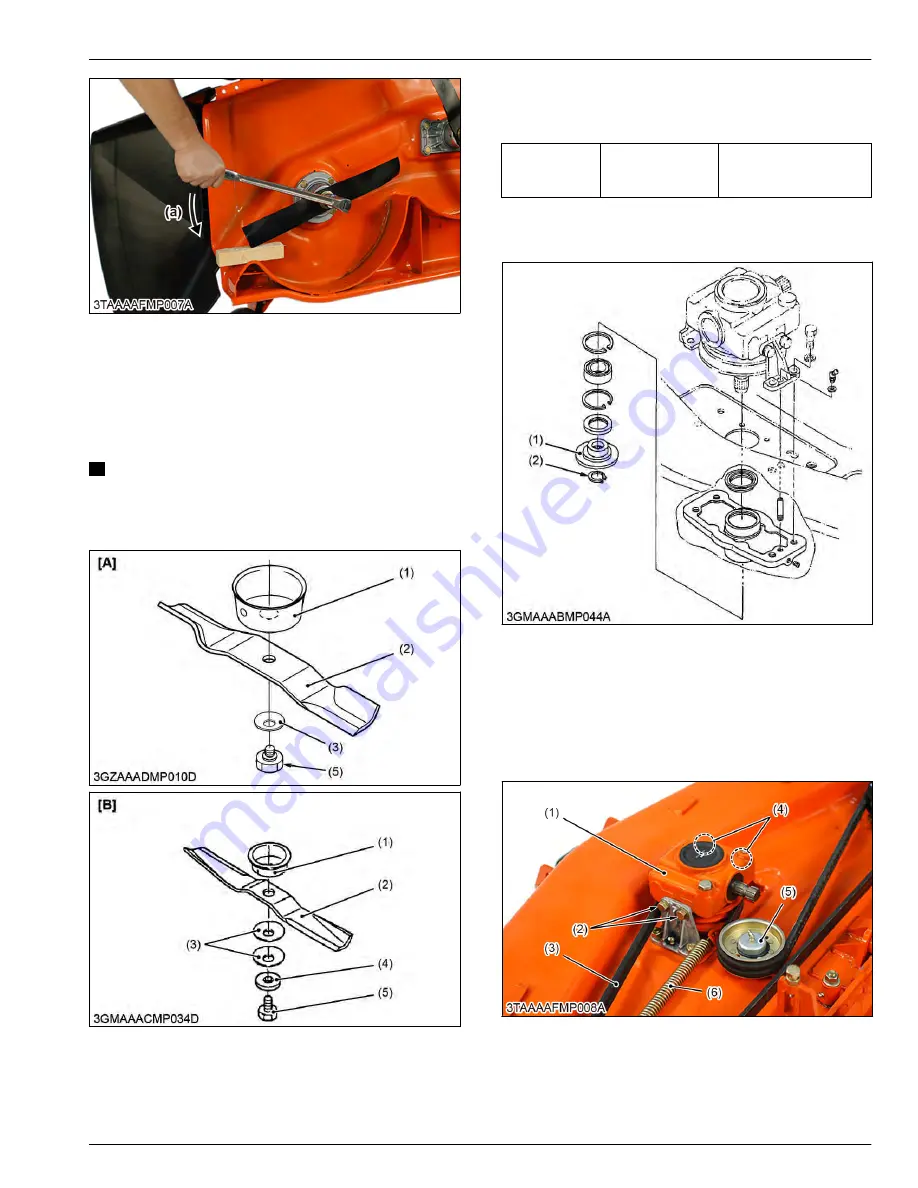

1. Turn over the mower.

2. Remove the mower blade screw (5), and remove

the lock washer (4), cup washer(s) (3), mower

blade (2) and dust cover (1).

(When reassembling)

IMPORTANT

• Make sure the cup washer is not flattened out or

worn, causing blade to slip easily.

Replace cup washer(s) if either is damaged.

(1) Dust cover

(2) Mower blade

(3) Cup washer

(4) Lock washer

(5) Mower blade screw

[A] RCK48-18BX and

RCK54-23BX

[B] RCK60B-23BX,

RCK54D-26BX, and

RCK60D-26BX

• Install the blade in position together with the dust

cover and the cup washer(s). Tighten them up with

the screw.

Tightening tor-

que

Mower blade

screw

103 to 117 N

⋅

m

10.5 to 12.0 kgf

⋅

m

76.0 to 86.7 lbf

⋅

ft

7.4 Removing blade boss

(1) Blade boss

(2) External circlip

1. Remove the external circlip (2).

2. Remove the blade boss (1).

7.5 Removing gear box and mower

belt

(1) Gear box

(2) Gear box mounting screw

(Reamer screw)

(3) Mower belt

(4) Gear box mounting screw

(5) Tension pulley

(6) Tension spring

1. Turn over the mower.

SERVICING

7. Disassembling and assembling

9. MOWER

BX1880,BX2380,BX2680,RCK60B-23BX,RCK54-23BX,RCK48-18BX,RCK60D-26BX,RCK54D-26BX

9-21

KiSC issued 03, 2019 A

Summary of Contents for ,RCK60B-23BX

Page 19: ...1 INFORMATION KiSC issued 03 2019 A ...

Page 42: ...2 GENERAL KiSC issued 03 2019 A ...

Page 111: ...3 ENGINE KiSC issued 03 2019 A ...

Page 190: ...4 TRANSAXLE KiSC issued 03 2019 A ...

Page 255: ...5 FRONT AXLE KiSC issued 03 2019 A ...

Page 274: ...6 STEERING KiSC issued 03 2019 A ...

Page 291: ...7 HYDRAULIC SYSTEM KiSC issued 03 2019 A ...

Page 344: ...8 ELECTRICAL SYSTEM KiSC issued 03 2019 A ...

Page 399: ...9 MOWER KiSC issued 03 2019 A ...