3. Check the fuel filter. If the fuel filter is clogged by

debris or contaminated by water, replace it.

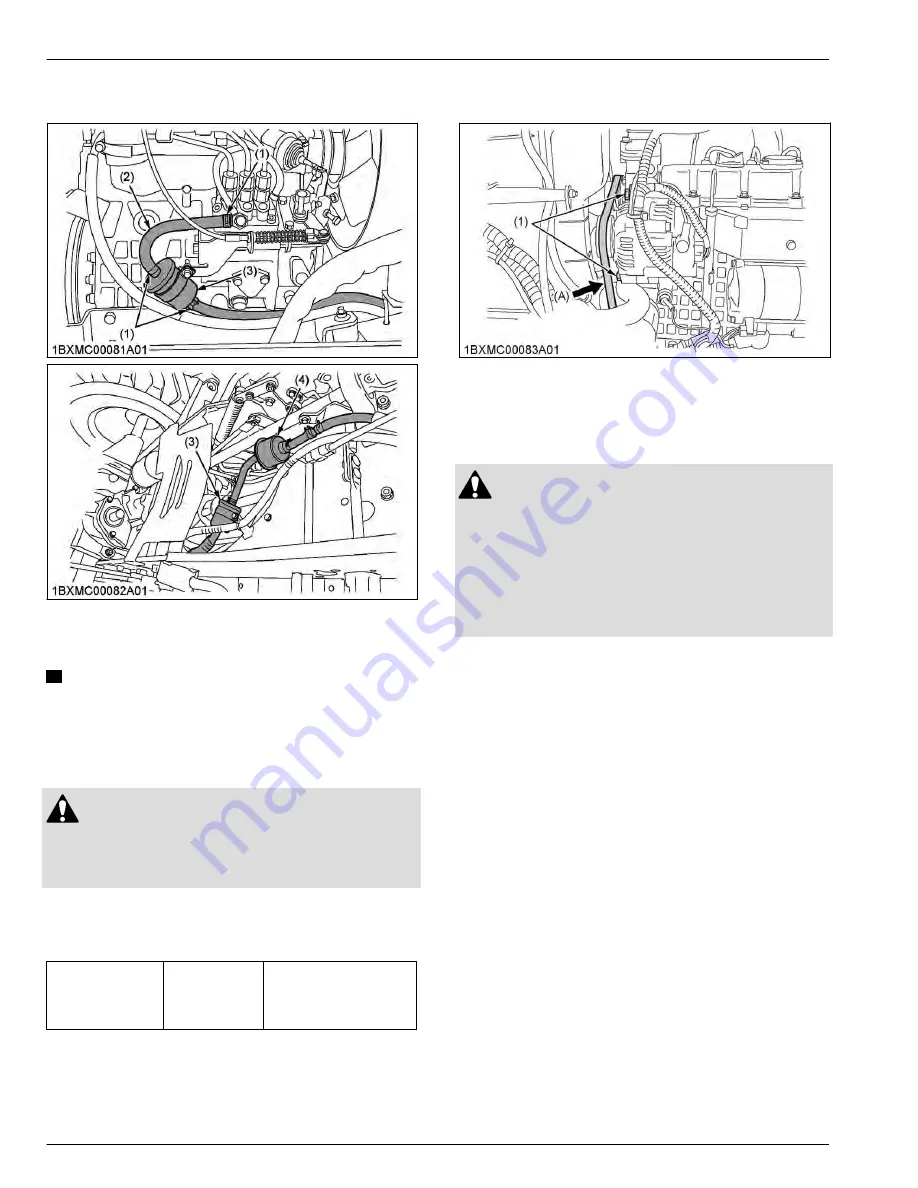

(1) Pipe clamps

(2) Fuel line

(3) Fuel filter

(4) Fuel pump

NOTE

• If the fuel line is removed, be sure to properly

bleed the fuel system.

1.5.4 Adjusting fan belt tension

WARNING

To avoid serious injury or death:

• Be sure to stop the engine and remove the key

before checking the fan belt tension.

1. Stop the engine and remove the key.

2. Apply moderate thumb pressure to belt between

pulleys.

Fan belt tension

Factory specifi-

cation

A deflection of between 7

to 9 mm (0.28 to 0.35 in.)

when the belt is pressed

in the middle of the span.

3. If tension is incorrect, loosen the alternator

mounting bolts and, using a lever placed between

the alternator and the engine block, pull the

alternator out until the deflection of the belt falls

within acceptable limits.

(1) Bolt

(A) Check the belt tension.

4. Replace fan belt if it is damaged.

1.5.5 Adjusting HST neutral spring

WARNING

• Do not operate if tractor moves on level ground

with foot off speed control pedal.

• If tractor moves on level ground with foot off

the pedal, or, if the pedal is too slow in

returning to neutral position when removing the

foot from the pedal, adjust the HST neutral

spring.

The HST neutral spring located under the front right

side of the fender can adjust returning speed of speed

control pedal. Since the HST neutral spring tension is

weakened, the HST tension should be checked and

adjusted every 100 hours.

Checking the HST neutral spring tension: Dynamic

braking

1. Start the engine and hold the maximum engine

speeds.

2. Operate the machine on the concrete level ground.

3. Shift the range gear shift lever to hi position.

4. Depress the speed control pedal to forward.

5. Release the foot from the speed control pedal.

6. Check the distance between the foot releasing point

(A) and the machine stopping point (B). If distance

(L) is more than approximately 3 m (10 ft.),

strengthen the HST neutral spring tension so that

the machine will stop in approximately 3 m (10 ft.)

after releasing the foot from the speed control

pedal.

2. GENERAL

CHECK AND MAINTENANCE

1. Periodic service

2-30

BX1880,BX2380,BX2680,RCK60B-23BX,RCK54-23BX,RCK48-18BX,RCK60D-26BX,RCK54D-26BX

KiSC issued 03, 2019 A

Summary of Contents for ,RCK60B-23BX

Page 19: ...1 INFORMATION KiSC issued 03 2019 A ...

Page 42: ...2 GENERAL KiSC issued 03 2019 A ...

Page 111: ...3 ENGINE KiSC issued 03 2019 A ...

Page 190: ...4 TRANSAXLE KiSC issued 03 2019 A ...

Page 255: ...5 FRONT AXLE KiSC issued 03 2019 A ...

Page 274: ...6 STEERING KiSC issued 03 2019 A ...

Page 291: ...7 HYDRAULIC SYSTEM KiSC issued 03 2019 A ...

Page 344: ...8 ELECTRICAL SYSTEM KiSC issued 03 2019 A ...

Page 399: ...9 MOWER KiSC issued 03 2019 A ...