(8) Mark

(9) Fan-shaped concave

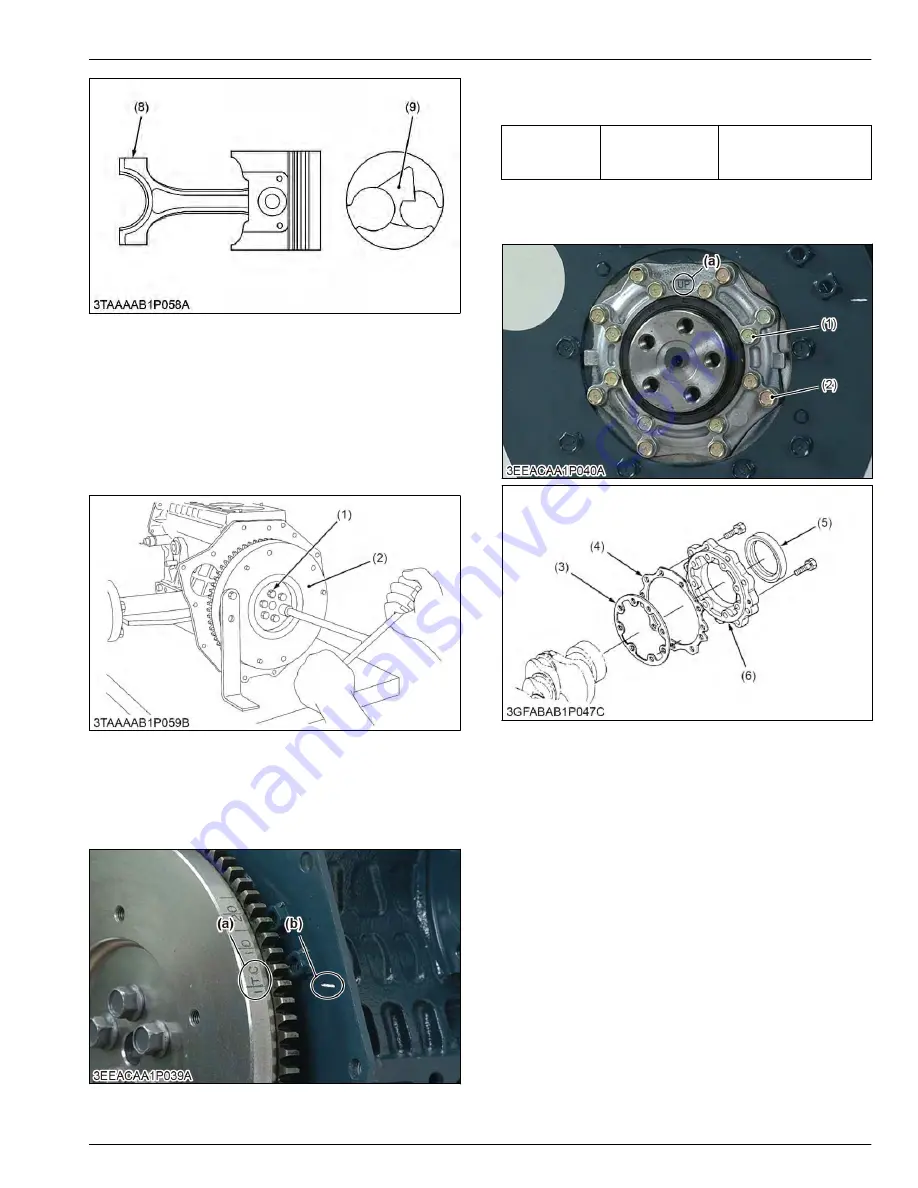

5.2.4 Flywheel and crankshaft

5.2.4.1 Removing flywheel

1. Secure the flywheel to keep it from turning, using a

flywheel stopper.

2. Remove all flywheel screws (1) and then remove

the flywheel (2).

(1) Flywheel screw

(2) Flywheel

(When reassembling)

• Align the

[1TC]

mark (a) on the outer surface of the

flywheel horizontally with the alignment mark (b) on

the rear end plate. Now fit the flywheel in position.

(a)

[1TC]

mark

(b) Alignment mark

• Apply engine oil to the threads and the undercut

surface of the flywheel screw and fit the screw.

Tightening tor-

que

Flywheel screw

54 to 58 N

⋅

m

5.5 to 6.0 kgf

⋅

m

40 to 43 lbf

⋅

ft

5.2.4.2 Removing bearing case cover

(1) Bearing case cover mount-

ing screw (Inside)

(2) Bearing case cover mount-

ing screw (Outside)

(3) Bearing case gasket

(4) Bearing case cover gasket

(5) Oil seal

(6) Bearing case cover

(a) Top mark

[UP]

1. Remove the bearing case cover mounting screws.

2. Remove the bearing case cover (6).

(When reassembling)

• Fit the bearing case gasket (3) and the bearing

case cover gasket (4) with correct directions.

SERVICING

5. Disassembling and assembling

3. ENGINE

BX1880,BX2380,BX2680,RCK60B-23BX,RCK54-23BX,RCK48-18BX,RCK60D-26BX,RCK54D-26BX

3-53

KiSC issued 03, 2019 A

Summary of Contents for ,RCK60B-23BX

Page 19: ...1 INFORMATION KiSC issued 03 2019 A ...

Page 42: ...2 GENERAL KiSC issued 03 2019 A ...

Page 111: ...3 ENGINE KiSC issued 03 2019 A ...

Page 190: ...4 TRANSAXLE KiSC issued 03 2019 A ...

Page 255: ...5 FRONT AXLE KiSC issued 03 2019 A ...

Page 274: ...6 STEERING KiSC issued 03 2019 A ...

Page 291: ...7 HYDRAULIC SYSTEM KiSC issued 03 2019 A ...

Page 344: ...8 ELECTRICAL SYSTEM KiSC issued 03 2019 A ...

Page 399: ...9 MOWER KiSC issued 03 2019 A ...