GENERAL

RTV1140CPX, WSM

G-6

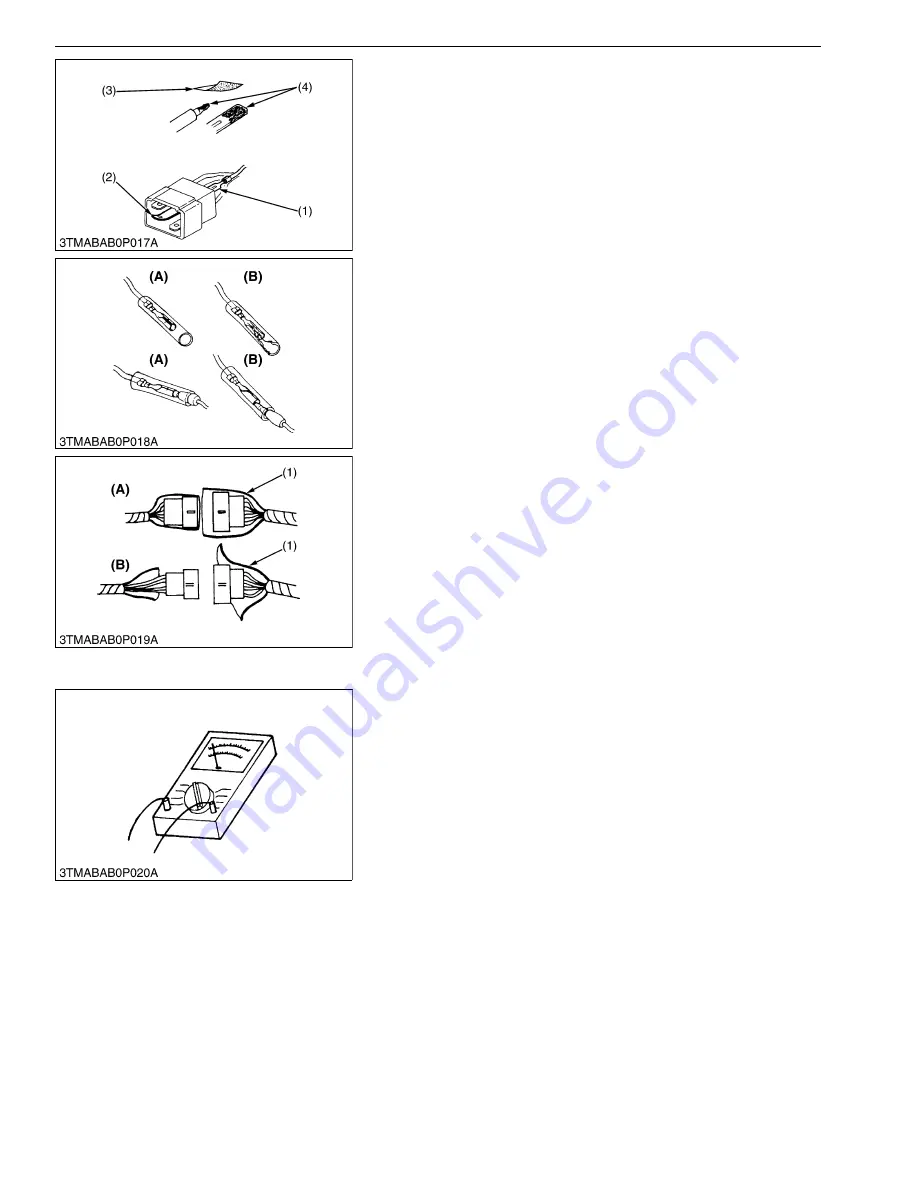

• Use sandpaper to remove rust from terminals.

• Repair deformed terminal. Make sure that there is no terminal

being exposed or displaced.

WSM000001GEG0075US0

• Make sure that there is no female connector being too open.

WSM000001GEG0076US0

• Make sure that plastic cover is large enough to cover whole

connector.

WSM000001GEG0077US0

[5] HANDLING OF CIRCUIT TESTER

• Use tester correctly following manual provided with tester.

• Check for polarity and range.

9Y1210301GEG0033US0

(1) Exposed Terminal

(2) Deformed Terminal

(3) Sandpaper

(4) Rust

(A) Correct

(B) Incorrect

(1) Cover

(A) Correct

(B) Incorrect

KiSC issued 05, 2014 A

Summary of Contents for RTV1140CPX

Page 1: ...RTV1140CPX WORKSHOP MANUAL UTILITY VEHICLE KiSC issued 05 2014 A...

Page 4: ...I INFORMATION KiSC issued 05 2014 A...

Page 10: ...INFORMATION RTV1140CPX WSM I 5 9Y1210293INI0002US0 KiSC issued 05 2014 A...

Page 11: ...INFORMATION RTV1140CPX WSM I 6 9Y1210293INI0003US0 KiSC issued 05 2014 A...

Page 12: ...INFORMATION RTV1140CPX WSM I 7 9Y1210293INI0004US0 KiSC issued 05 2014 A...

Page 13: ...INFORMATION RTV1140CPX WSM I 8 9Y1210293INI0005US0 KiSC issued 05 2014 A...

Page 14: ...INFORMATION RTV1140CPX WSM I 9 9Y1210293INI0006US0 KiSC issued 05 2014 A...

Page 15: ...INFORMATION RTV1140CPX WSM I 10 9Y1210293INI0007US0 KiSC issued 05 2014 A...

Page 19: ...INFORMATION RTV1140CPX WSM I 14 5 DIMENSIONS 9Y1210293INI0012US0 KiSC issued 05 2014 A...

Page 20: ...G GENERAL KiSC issued 05 2014 A...

Page 77: ...1 ENGINE KiSC issued 05 2014 A...

Page 138: ...2 TRANSMISSION KiSC issued 05 2014 A...

Page 215: ...3 REAR AXLE KiSC issued 05 2014 A...

Page 216: ...CONTENTS 1 STRUCTURE 3 M1 MECHANISM KiSC issued 05 2014 A...

Page 227: ...4 BRAKES KiSC issued 05 2014 A...

Page 254: ...5 FRONT AXLE KiSC issued 05 2014 A...

Page 283: ...6 STEERING KiSC issued 05 2014 A...

Page 306: ...7 HYDRAULIC SYSTEM KiSC issued 05 2014 A...

Page 328: ...8 ELECTRICAL SYSTEM KiSC issued 05 2014 A...

Page 330: ...ELECTRICAL SYSTEM RTV1140CPX WSM 8 M1 1 WIRING DIAGRAM KiSC issued 05 2014 A...