29

EXCAVATOR OPERATION

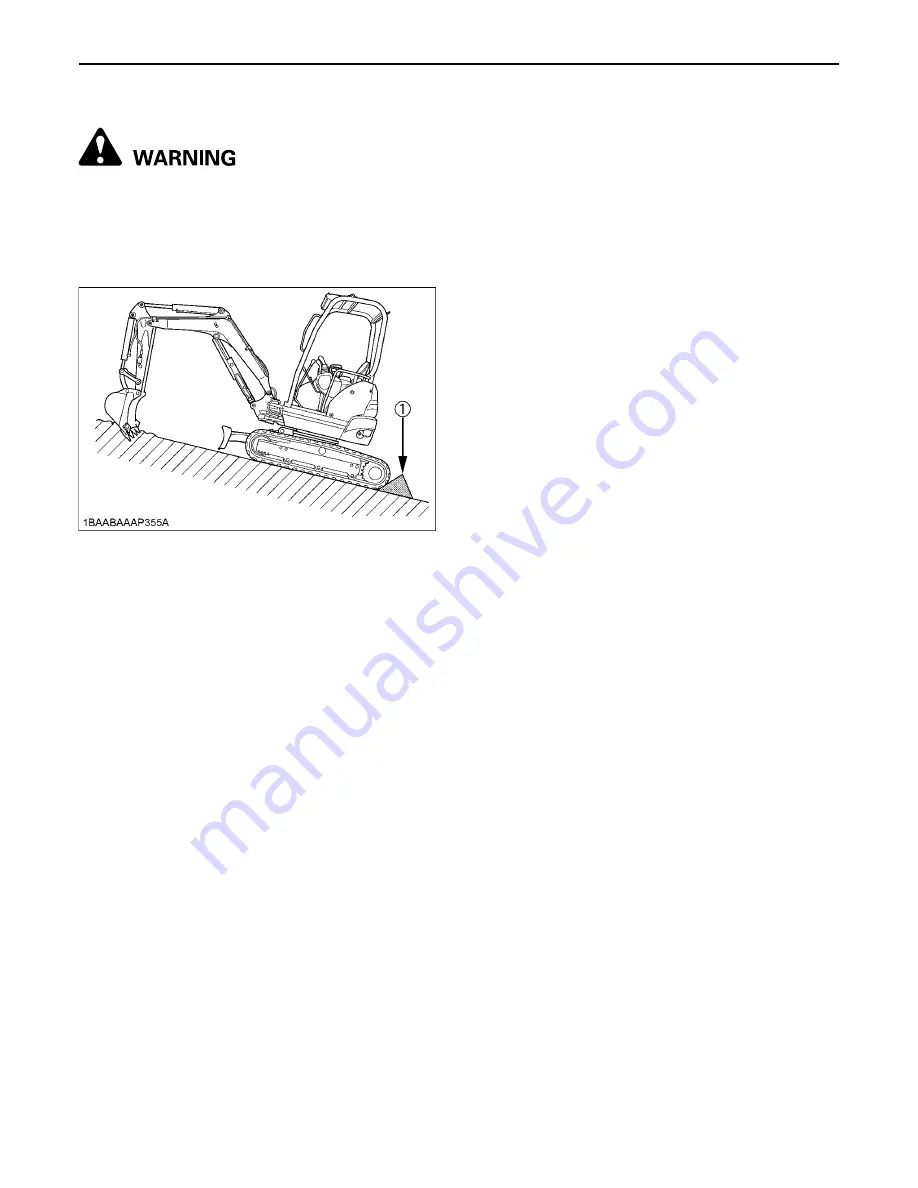

PARKING ON A SLOPE

To avoid personal injury or death:

A

When the excavator is parked or left

unattended on a slope, be sure to put the

bucket on the ground and place all control

levers in neutral position, then brace the tracks

with chocks.

IMPORTANT INFORMATION ON

EXCAVATOR OPERATION

A

Do not try to crush concrete or boulders using side

swings with the bucket. Also avoid using side sweeps

of the bucket to move earth piles.

A

Under all circumstances avoid the following

operations:

A

Excavation using the gravitational impact of the

machine.

A

Compacting of gravel or soil using the dropping

action of the bucket.

A

Excavation using the traveling power of the

machine.

A

Do not try to drop or shake off soil adhering to the

bucket in the manner given in the points below. This

can cause damage to the machine.

Adhering soil can be shaken off when the bucket is

being emptied by moving the bucket out to the

maximum stroke of the cylinder. Should this not

suffice, swing out the arm as far as possible and

operate the bucket back and forth.

A

Do not hit the dozer with the boom cylinder!

Make sure that the boom cylinder does not hit the

dozer when doing deep excavation. If necessary

swing around so that the dozer is in the back of the

machine.

A

Pay attention when pulling in the bucket!

When pulling in the bucket (for driving or

transportation) avoid hitting the dozer.

A

Avoid collisions!

When moving the excavator, pay attention that the

dozer does not collide with obstructions such as

boulders, etc.

Such collisions shorten the life of the dozer and the

cylinder substantially.

A

Support the machine correctly!

When stabilizing the machine with the dozer, lower the

dozer to engage the full width on the ground.

A

If the water or mud level reaches higher than the top of

the tracks, the swivel bearing, swivel motor gear and

ring gear may be exposed to mud, water and other

foreign objects.

The excavator must be properly pressure washed

after each use.

A

Thoroughly clean the area around the swivel

bearing, swivel motor gear and ring gear to remove

foreign objects.

A

Inspect the swivel motor oil sump (if equipped) for

water contamination. If water is present, refer to

operator's manual for lubricant replacement

procedure.

A

Refer to operator's manual for proper swivel

bearing, swivel motor gear and ring gear

lubrication procedures.

A

Reinstall any protective covering if removed

earlier.

(1) Chock

Summary of Contents for u25

Page 8: ......

Page 15: ... 7 SAFE OPERATION ...

Page 16: ...SAFE OPERATION 8 ...

Page 17: ... 9 SAFE OPERATION ...

Page 18: ...SAFE OPERATION 10 ...

Page 20: ......

Page 90: ...70 LIFTING CAPACITY ...