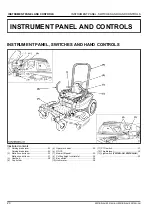

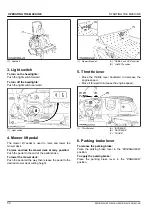

(1) Parking brake lever

(A)

“ENGAGED”

(B)

“DISENGAGED”

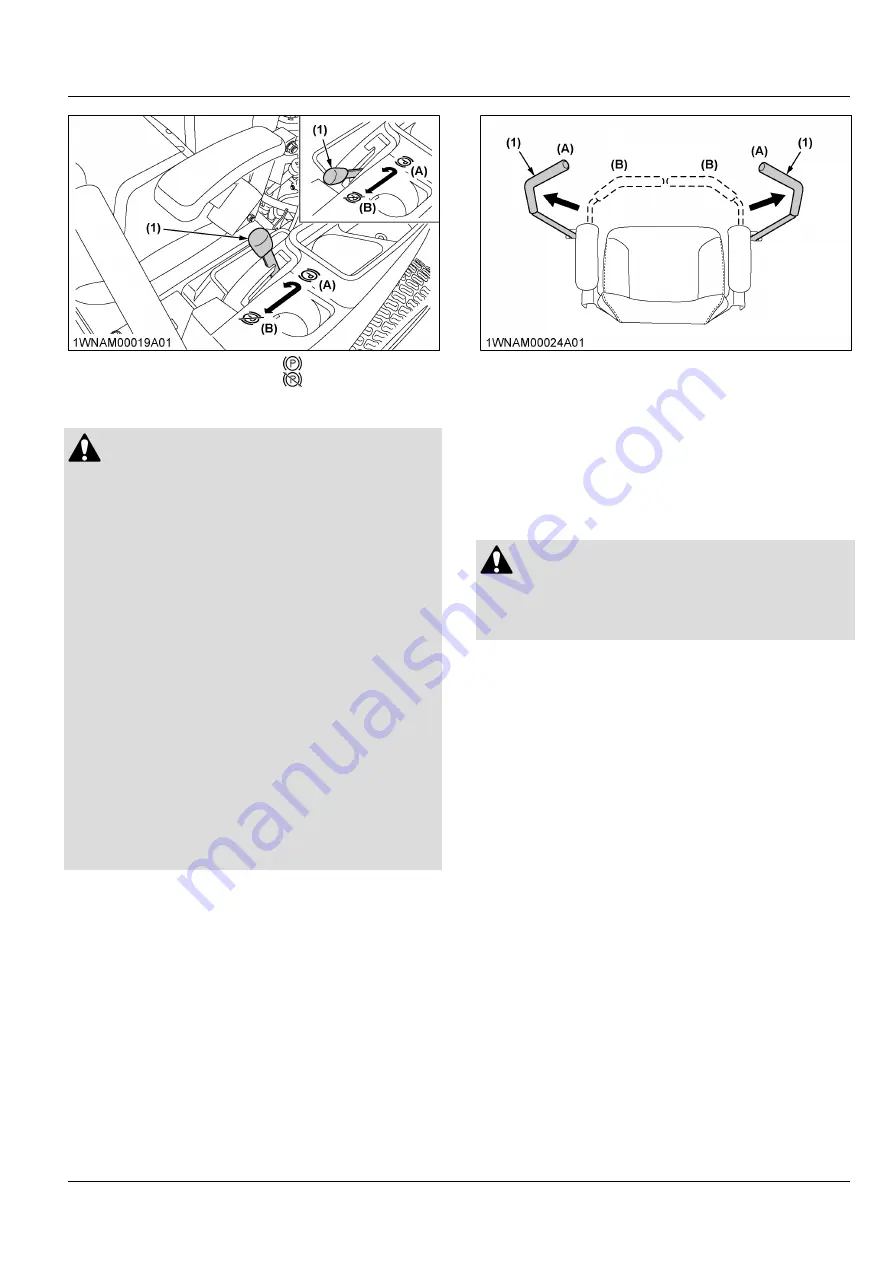

7. Motion control lever

WARNING

To avoid serious injury or death:

• Understand how to use the motion control

levers and practice in an unrestricted area at

slightly more than idle speed without the mower

engaged until becoming proficient in the

operation of the machine.

• Do not move motion control levers from the

“FORWARD” to “REARWARD” or from the

“REARWARD” to “FORWARD” position rapidly.

Sudden direction changes could cause the loss

of control or damage to the machine or

property.

• Do not make sharp turns at high speed.

Fast and sharp turns could cause the loss of

control.

• Motion control levers must be in the “NEUTRAL

LOCK” position to safely enter and exit the

operator's seat or to carry out maintenance and

safety checks.

• This machine can make sharp turns. Always

make sure your intended path is clear of

obstructions or people.

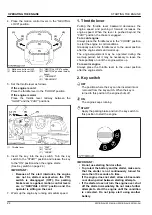

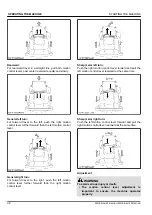

7.1 Stop position of the motion control

lever

Neutral lock position

Forward and rearward movements of the motion control

levers are locked when these levers are in the

“NEUTRAL LOCK”

position (the engine can only be

started with levers in this position).

(1) Motion control levers

(A) “NEUTRAL LOCK” position

(B) “NEUTRAL” position (held by

hand)

7.2 Operating position of the motion

control lever

Machine speed and steering is controlled by the motion

control levers, when the engine is running and the

parking brake is released.

WARNING

To avoid serious injury or death:

• No control is provided by the motion control

levers when the engine is off.

Neutral position

Grasp the motion control levers and move them inward

from the

“NEUTRAL LOCK”

position so that the

machine is in

“NEUTRAL”

(the engine cannot be

restarted).

Forward and rearward motion:

1. Move the throttle lever to the

“FAST”

position.

2. Release the parking brake.

3. Move both motion control levers from the

“NEUTRAL LOCK”

position inward to the

“NEUTRAL”

position.

4. To move your machine, see the following figures.

To stop:

Move and hold both motion control levers to the

“NEUTRAL”

position until the machine comes to a

stop.

Forward:

For forward travel in a straight line, push both motion

control levers forward equally and slowly.

STARTING THE MACHINE

OPERATING THE MACHINE

Z231BR-AU,Z231KH-AU,Z251BR-AU,Z251KH-AU

31

Summary of Contents for Z231BR-AU

Page 7: ...4 Z231BR AU Z231KH AU Z251BR AU Z251KH AU ...

Page 13: ...SAFETY LABELS SAFE OPERATION 10 Z231BR AU Z231KH AU Z251BR AU Z251KH AU ...

Page 14: ...SAFE OPERATION Z231BR AU Z231KH AU Z251BR AU Z251KH AU 11 ...

Page 15: ...SAFE OPERATION 12 Z231BR AU Z231KH AU Z251BR AU Z251KH AU ...

Page 16: ...SAFE OPERATION Z231BR AU Z231KH AU Z251BR AU Z251KH AU 13 ...

Page 85: ...wheels 38 82 Z231BR AU Z231KH AU Z251BR AU Z251KH AU ...