avoid affecting the machine operation, fill the

fuel tank at the end of daily operations.

Use of alcohol mixed gasoline (gasohol)

Use

“gasohol”

only when the ethanol additive is less

than 10% of the fuel. The use of methanol additive is

not recommended. For best results, use unleaded fuel

with a minimum of 87 octane.

3. Checking and cleaning the air

intake screen

WARNING

To avoid serious injury or death:

• Be sure to stop the engine and remove the key

before cleaning.

• Make sure that the engine is cool to the touch

before cleaning.

IMPORTANT :

• The air intake screen and air intake area must

be clear of debris to prevent the engine from

overheating.

Daily or after every 5 hours of operation, make sure the

air intake screen and the air intake area are clean.

Dirt or chaff around the air intake screen, air intake

area, or the engine cooling area decrease cooling

performance.

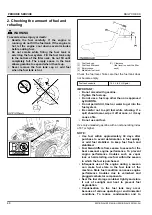

1. Check that the air intake screen is clear of grass

clippings and debris.

2. If the screen is dirty, clean it with a brush or cloth.

3. Remove the dust and all foreign material from the

engine plate.

(1) Air intake screen

(2) Engine plate

4. Checking the tire pressure

WARNING

To avoid serious injury or death:

• Do not attempt to mount a tire on a rim. This

should be done by a qualified person with the

proper equipment.

• Always maintain the correct tire pressure.

The inflation pressure in the front tires rises

quickly when using compressed air.

Do not inflate the tires above the recommended

pressure shown in the operator's manual.

IMPORTANT :

• Do not use tires larger than specified.

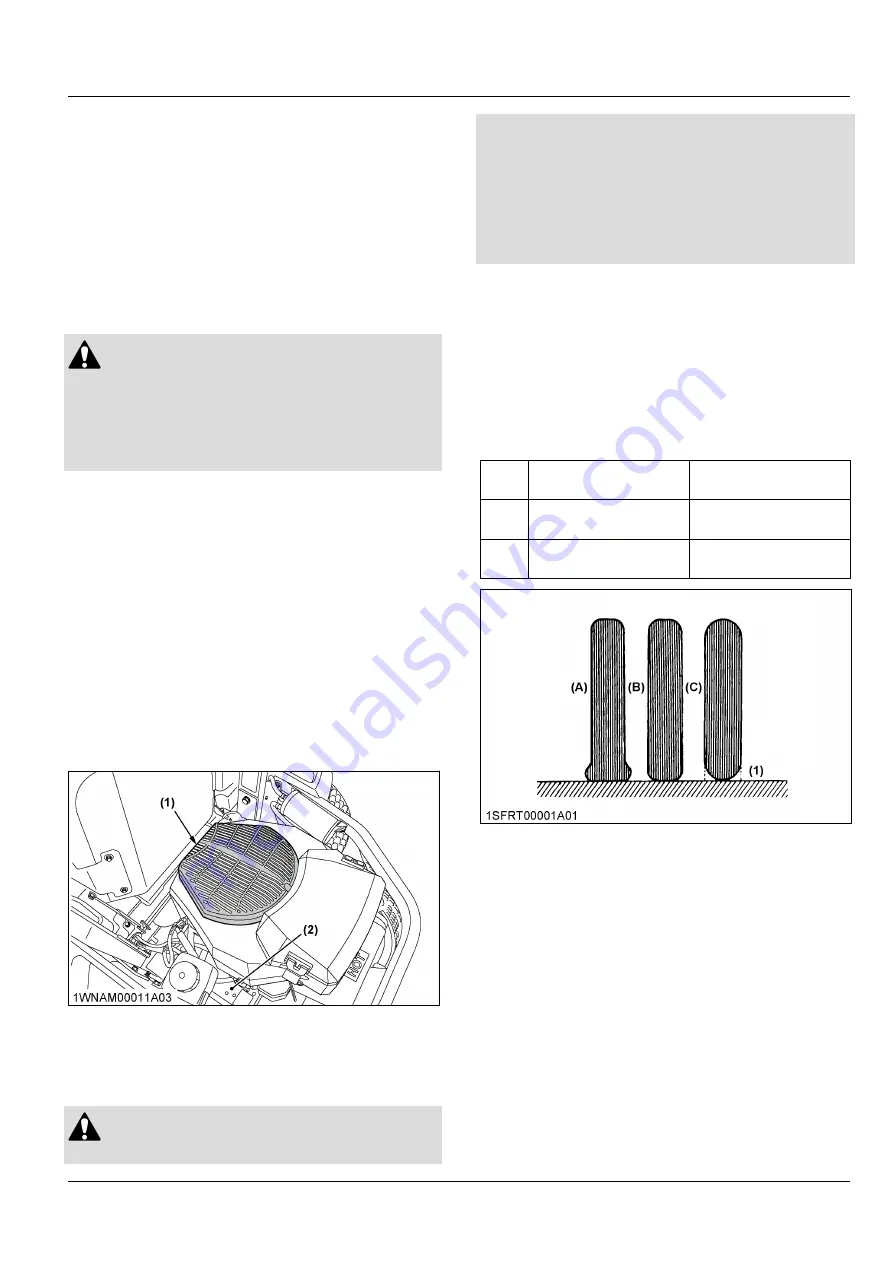

5. Inflation pressure

Even though the inflation pressure is factory-set to the

prescribed level, it naturally drops slowly in the course

of time. Therefore, check it everyday and inflate as

necessary.

Tire sizes

Recommended inflation

pressure

Front

11 × 4 - 5, 4PR smooth

170 kPa

(1.7 kgf/cm

2

, 25 psi)

Rear

22 × 10 - 14, 4PR turf

110 kPa

(1.1 kgf/cm

2

, 16 psi)

(1) Ground

(A) “INSUFFICIENT”

(B) “NORMAL”

(C) “EXCESSIVE”

6. Checking transaxle fluid level

1. Park the machine on a flat surface, lower the

implement to the ground and shut off the engine

and remove the key.

DAILY CHECK

PERIODIC SERVICE

Z231BR-AU,Z231KH-AU,Z251BR-AU,Z251KH-AU

47

Summary of Contents for Z231BR-AU

Page 7: ...4 Z231BR AU Z231KH AU Z251BR AU Z251KH AU ...

Page 13: ...SAFETY LABELS SAFE OPERATION 10 Z231BR AU Z231KH AU Z251BR AU Z251KH AU ...

Page 14: ...SAFE OPERATION Z231BR AU Z231KH AU Z251BR AU Z251KH AU 11 ...

Page 15: ...SAFE OPERATION 12 Z231BR AU Z231KH AU Z251BR AU Z251KH AU ...

Page 16: ...SAFE OPERATION Z231BR AU Z231KH AU Z251BR AU Z251KH AU 13 ...

Page 85: ...wheels 38 82 Z231BR AU Z231KH AU Z251BR AU Z251KH AU ...