6. Install the new filter by hand, turn 3/4 to 1 full turn

after the filter gasket contacts the filter base

surface.

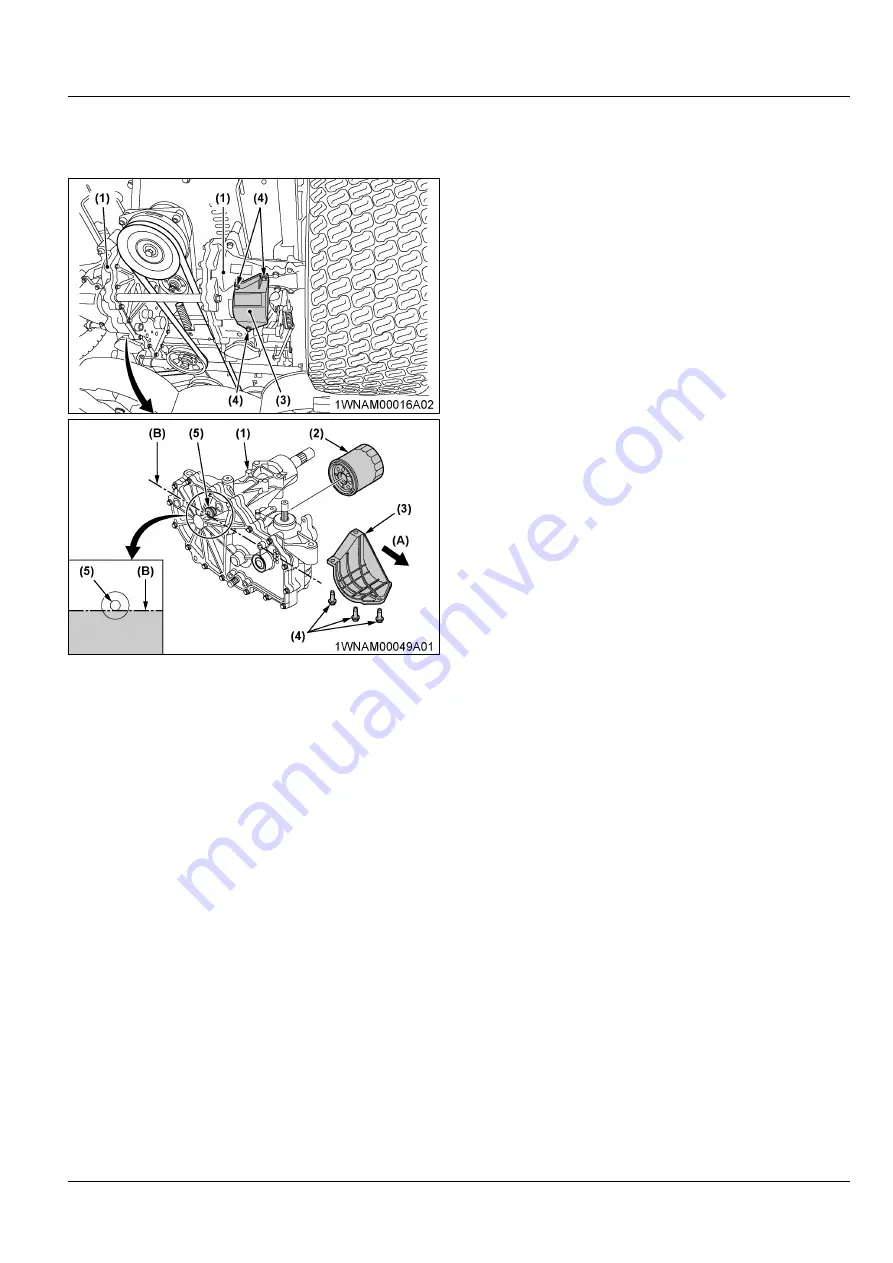

(1) Transaxle

(2) Transaxle oil filter

(3) Filter guard

(4) Hex flange head bolt

(5) Breather port plug

(A) “FRONT”

(B) “OIL LEVEL”

7. Re-install the filter guard (3) with 3 hex head bolts

(4).

Torque bolts (4) to 7.35 N

⋅

m (5.42 lbf

⋅

ft) securely.

8. Repeat steps 2-7 on the opposite side transaxle

drive.

9. Drain old oil filters of all free flowing oil prior to

disposal. Place used oil in appropriate containers

and deliver to an approved recycling collection

facility.

10. Remove the breather port plug (9) from the left side

and right side transaxles prior to filling with oil. This

will allow the transaxles to vent during oil fill.

11. Remove the cap from the transaxle fluid tank

located on the machine frame.

12. Fill with 20W-50 motor oil until oil just appears at

the bottom of the breather port. Install the breather

port plug (5) into transaxle. Torque the plug (5) to

20.34 N

⋅

m (15.0 lbf

⋅

ft).

13. Continue to fill the transaxles through the transaxle

fluid tank until the

“Full Cold”

line is reached on the

transaxle fluid tank.

14. Re-install the transaxle fluid tank cap by hand. Be

careful to not overtighten.

15. Proceed to the purge procedure.

Purging procedures

Due to the effects air has on efficiency in hydrostatic

drive applications, it is critical that it is purged from the

system.

Air creates inefficiency because its compression and

expansion rate is higher than that of the oil approved

for use in hydrostatic drive systems.

These purge procedures should be implemented any

time a hydrostatic system has been opened to facilitate

maintenance or the oil has been changed.

The resulting symptoms in hydrostatic systems may be:

1. Noisy operation.

2. Lack of power or drive after short term operation.

3. High operation temperature and excessive

expansion of oil.

Before starting, make sure the transaxle is at the

proper oil level. If it is not, fill to the specifications

outlined in this manual.

The following procedures are best performed with the

machine drive wheels off the ground. Then repeated

under normal operating conditions. If this is not

possible, then the procedure should be performed in an

open area free of any objects or bystanders.

1. Disengage the brake if activated.

2. With the bypass valve open and the engine

running, slowly move the motion control levers in

both forward and reverse directions (5 or 6 times).

3. With the bypass valve closed and the engine

running, slowly move the motion control levers in

both forward and reverse directions (5 to 6 times).

Check the oil level, and add oil as required after

stopping the engine.

4. It may be necessary to repeat Steps 2 and 3 until

all the air is completely purged from the system.

When the transaxle operates at normal noise levels

and moves smoothly forward and reverse at normal

speeds, then the transaxle is considered purged.

2. Changing transaxle fluid

(See Replacing transaxle oil filter on page 60.)

EVERY 500 HOURS

1. Adjusting the electric clutch

This adjustment should be done every 500 hours of

operation or annually, whichever comes first. In case

the machine is heavily used, air gap settings should be

checked more often.

The electric clutch serves 2 functions in the operation

of the mower:

• Starting and stopping the power flow to the cutter

blades.

• The clutch also acts as a brake to assist in stopping

blade rotation when the PTO is switched off or the

operator presence control is interrupted.

EVERY 400 HOURS

PERIODIC SERVICE

Z231BR-AU,Z231KH-AU,Z251BR-AU,Z251KH-AU

61

Summary of Contents for Z231BR-AU

Page 7: ...4 Z231BR AU Z231KH AU Z251BR AU Z251KH AU ...

Page 13: ...SAFETY LABELS SAFE OPERATION 10 Z231BR AU Z231KH AU Z251BR AU Z251KH AU ...

Page 14: ...SAFE OPERATION Z231BR AU Z231KH AU Z251BR AU Z251KH AU 11 ...

Page 15: ...SAFE OPERATION 12 Z231BR AU Z231KH AU Z251BR AU Z251KH AU ...

Page 16: ...SAFE OPERATION Z231BR AU Z231KH AU Z251BR AU Z251KH AU 13 ...

Page 85: ...wheels 38 82 Z231BR AU Z231KH AU Z251BR AU Z251KH AU ...