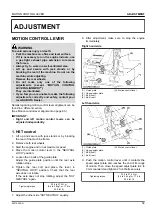

4. Move the choke knob to the

“ON”

position. Make

sure that the carburetor choke valve is completely

closed. Make sure that the choke valve turns from

fully closed position to fully opened position when

actuating the choke knob.

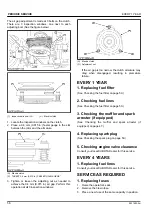

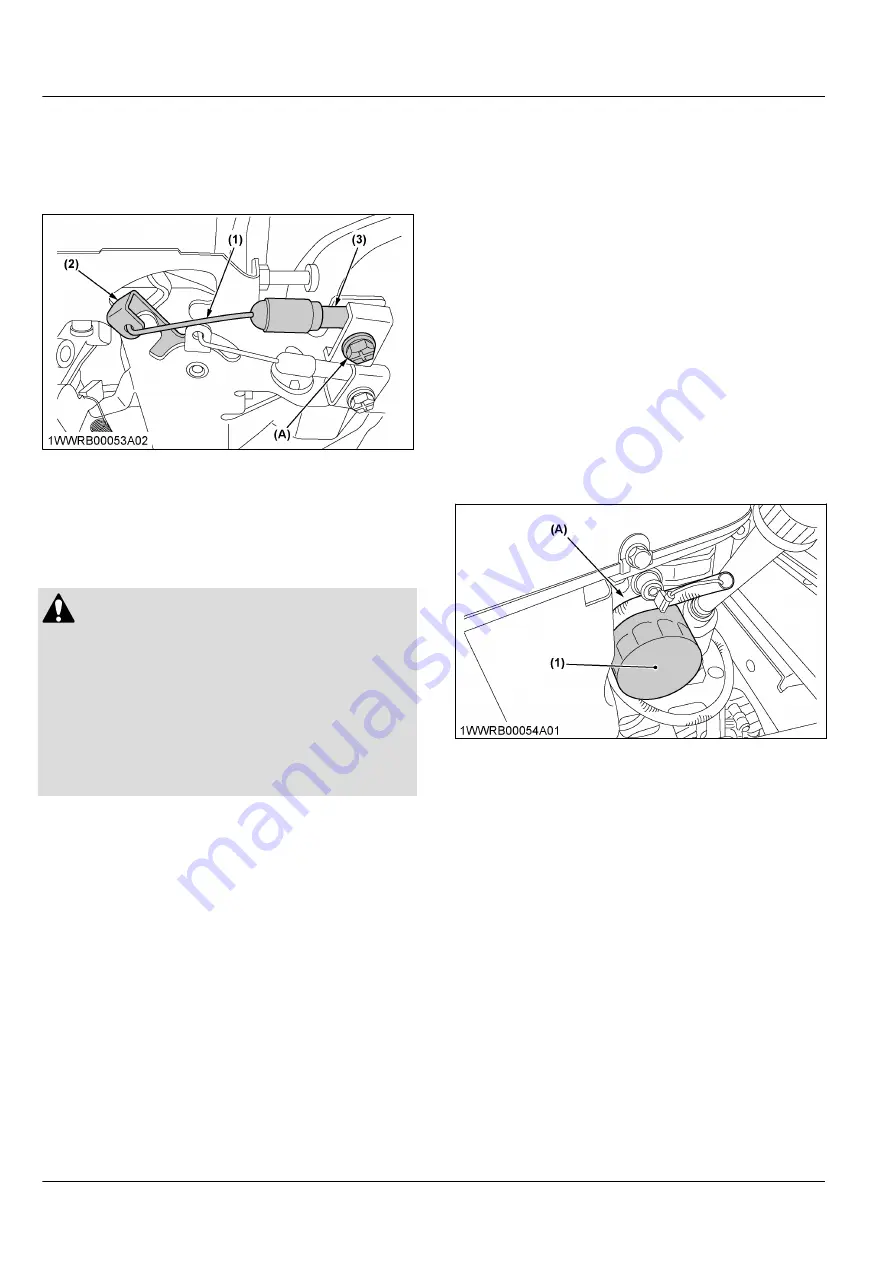

(1) Choke cable

(2) Choke control lever

(3) Choke cable sheath

(A) Choke cable clamp bolt

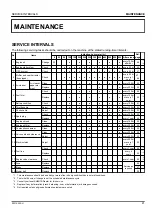

EVERY 200 HOURS

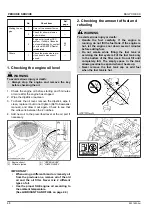

1. Replacing the engine oil filter

WARNING

To avoid serious injury or death:

• Engine oil is a toxic substance. Dispose of used

oil properly. Contact your local authorities for

approved disposal methods or possible

recycling.

• Be sure to stop the engine and remove the key

before changing the oil and the oil filter.

• Allow the engine to cool down sufficiently. Oil

can be hot and may cause burns.

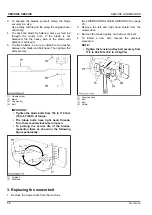

The oil filter must be changed every 200 service hours.

Always use a genuine oil filter.

1. The drain plug is located on the starter side of the

oil pan. Clean the area around the oil drain plug and

the oil fill cap/dipstick.

2. Remove the drain plug and the oil fill cap/dipstick.

3. Allow the oil to drain and then reinstall the drain

plug.

4. Remove the old filter and wipe off the filter adapter

with a clean cloth.

5. Place a new replacement filter in a shallow pan with

the open end up. Pour new oil, of the proper type, in

the threaded center hole. Stop pouring when the oil

reaches the bottom of the threads. Allow a few

minutes or 2 for the oil to be absorbed by the filter

material.

6. Apply a thin film of clean oil to the rubber gasket on

the new oil filter.

7. Install the new oil filter to the filter adapter. Hand

tighten the filter clockwise until the rubber gasket

contacts the adapter, then tighten the filter an

additional 3/4 to 1 turn.

8. Fill the engine with the proper oil to the

[FULL]

or

[F]

mark on the dipstick. Always check the oil level

with the dipstick before adding more oil.

9. Reinstall the oil fill cap/dipstick and tighten securely.

10. Start the engine and check for oil leakage. Recheck

the oil level before placing the engine into service.

Stop the engine, correct any leakage, and allow 1

minute for the oil to drain down, then recheck the

level on the dipstick.

NOTE :

• To prevent extensive engine wear or

damage, always maintain the proper oil level

in the crankcase. Never operate the engine

with the oil level below the [ADD] or [L] mark

or above the [FULL] or [F] mark on the

dipstick.

(1) Engine oil filter

(A) “MOUNTING SURFACE”

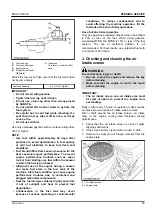

2. Replacing the air cleaner paper

element

Every 200 hours of operation or annually replace the

paper element.

PERIODIC SERVICE

EVERY 200 HOURS

54

Z231KW-AU

Summary of Contents for Z231KW-AU

Page 7: ...4 Z231KW AU ...

Page 13: ...SAFETY LABELS SAFE OPERATION 10 Z231KW AU ...

Page 14: ...SAFE OPERATION Z231KW AU 11 ...

Page 15: ...SAFE OPERATION 12 Z231KW AU ...

Page 16: ...SAFE OPERATION Z231KW AU 13 ...

Page 66: ... 1 Cutting height fine tuning bolt 2 Jam nut MOWER DECK LEVEL ADJUSTMENT Z231KW AU 63 ...