• Remove accumulated debris from the muffler

area and cylinder area.

• It is a violation of California Public Resource

Code, Section 4442, to use or operate the

engine on any forest-covered, brush-covered,

or grass-covered land unless the exhaust

system is equipped with a spark arrester, as

defined in Section 4442, maintained in effective

working order. Other states or federal

jurisdictions may have similar laws. Contact the

original equipment manufacturer, retailer, or

dealer to obtain a spark arrester designed for

the exhaust system installed on this engine.

• Replacement parts must be of the same design

and installed in the same position as the

original parts. Other parts may not perform as

well, may damage the unit, and may result in

injury.

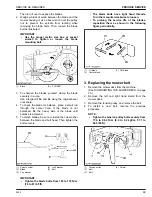

1. Remove accumulated debris from the muffler and

cylinder area.

2. Inspect the muffler for cracks, corrosion, or other

damage.

3. Remove the spark arrester, if equipped, and inspect

for damage or carbon blockage.

4. If damage is found, install replacement parts before

operating.

(1) Muffler

EVERY 100 HOURS

1. Changing the engine oil

WARNING

To avoid serious injury or death:

• Be sure to stop the engine and remove the key

before changing the oil.

• Allow the engine to cool down sufficiently, as

oil can be hot and may cause burns.

1. To change the used oil, use the oil drain valve

connected to the engine block. To drain the oil,

loosen the hex plug until oil begins to drain. Then,

remove the oil level dipstick to allow the engine to

vent.

NOTE :

• The used oil can be drained out more easily

if the engine is warm.

(1) Oil drain valve

(2) Hex plug

(3) Engine block

2. After all the used oil has drained, tighten the hex

plug.

3. Fill with new oil up to the upper level on the dipstick.

(1) Engine oil port

(2) Oil level dipstick

(A) “UPPER LEVEL”

(B) “LOWER LEVEL”

4. To check the oil level:

Remove the dipstick, wipe it clean, insert it without

screwing it in and draw it out again. Check to see

that the oil level is between the 2 marks.

NOTE :

• Do not overfill.

2. Cleaning the air cleaner paper

element

(See Cleaning the foam element on page 55.)

PERIODIC SERVICE

EVERY 100 HOURS

58

Z400

Summary of Contents for Z411

Page 3: ...OPERATOR S MANUAL 1SFRT00108A01 READ AND SAVE THIS MANUAL MODELS Z411 Z421 Z421T ...

Page 9: ...4 Z400 ...

Page 16: ...SAFETY LABELS SAFE OPERATION Z400 11 ...

Page 17: ...SAFE OPERATION 12 Z400 ...

Page 18: ...SAFE OPERATION Z400 13 ...

Page 19: ...SAFE OPERATION 14 Z400 ...

Page 20: ...SAFE OPERATION Z400 15 ...

Page 53: ...PERIODIC SERVICE CHART LABEL MAINTENANCE PERIODIC SERVICE CHART LABEL 48 Z400 ...