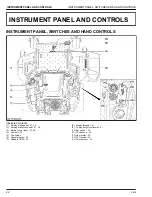

(1) Parking brake pedal

(2) Parking brake lock pedal

(3) Right foot

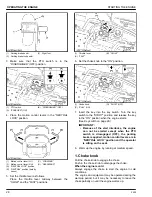

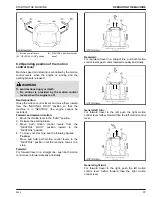

3. Make sure that the PTO switch is in the

“DISENGAGED”

(OFF) position.

(1) PTO switch

(A) “ENGAGED” (ON)

(B) “DISENGAGED” (OFF)

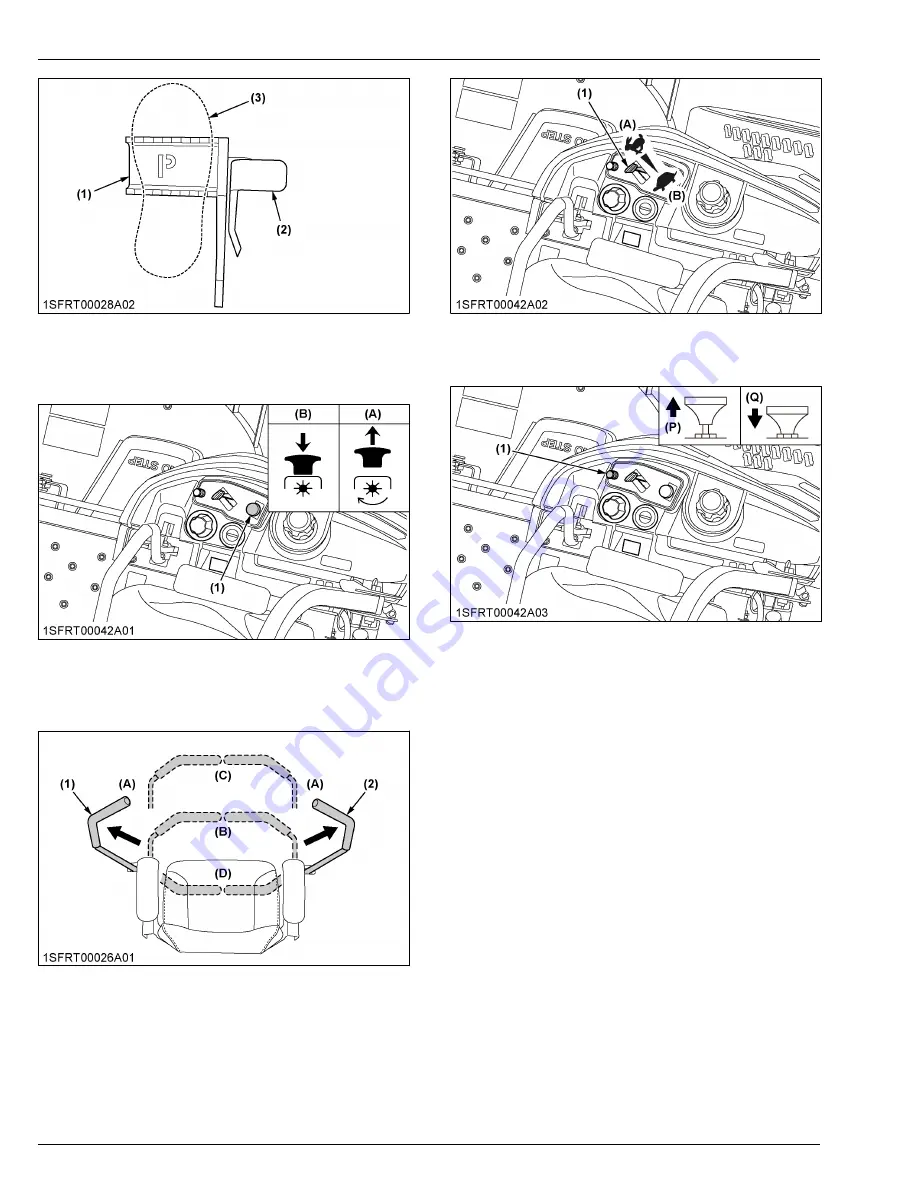

4. Place the motion control levers in the

“NEUTRAL

LOCK”

position.

(1) Motion control lever (LH)

(2) Motion control lever (RH)

(A) “NEUTRAL LOCK” position

(B) “NEUTRAL” position (held by

hands)

(C) “FORWARD”

(D) “REARWARD”

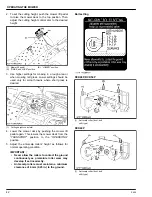

5. Set the throttle lever as follows.

Place the throttle lever midway between the

“SLOW”

and the

“FAST”

positions.

(1) Throttle lever

(A) “FAST”

(B) “SLOW”

6. Set the choke knob to the

“ON”

position.

(1) Choke knob

(P) “PULL” (ON)

(Q) “PUSH” (OFF)

7. Insert the key into the key switch. Turn the key

switch to the

“START”

position and release the key

to the

“ON”

position when the engine starts.

IMPORTANT :

• Because of the start interlocks, the engine

can not be started except when the PTO

switch is disengaged (OFF), the parking

brake is applied, motion control levers are in

“NEUTRAL LOCK” position and the operator

is sitting on the seat.

8. Warm up the engine by running at medium speed.

1. Choke knob

Pull the choke knob to engage the choke.

Push in the choke knob to disengage the choke.

When the engine is cold

Always engage the choke to start the engine in cold

conditions.

The engine and equipment may be operated during the

warmup period, but it may be necessary to leave the

choke partially on until the engine warms up.

OPERATING THE ENGINE

STARTING THE ENGINE

28

Z400

Summary of Contents for Z411

Page 3: ...OPERATOR S MANUAL 1SFRT00108A01 READ AND SAVE THIS MANUAL MODELS Z411 Z421 Z421T ...

Page 9: ...4 Z400 ...

Page 16: ...SAFETY LABELS SAFE OPERATION Z400 11 ...

Page 17: ...SAFE OPERATION 12 Z400 ...

Page 18: ...SAFE OPERATION Z400 13 ...

Page 19: ...SAFE OPERATION 14 Z400 ...

Page 20: ...SAFE OPERATION Z400 15 ...

Page 53: ...PERIODIC SERVICE CHART LABEL MAINTENANCE PERIODIC SERVICE CHART LABEL 48 Z400 ...