2. Lubricating the crank shaft

WARNING

To avoid serious injury or death:

• Park the machine on a firm and level surface.

• Apply the parking brake.

• Stop the engine and remove the key before

lubricating the crankshaft.

The engine crank shaft should be lubricated every 500

hours to ensure that critical components such as the

electric clutch, transaxle drive pulley and the engine

can be removed if needed.

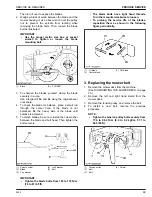

1. Remove the mower belt.

2. Remove the transaxle belt.

3. Remove the electric clutch and transaxle drive

pulley.

(1) Transaxle belt

(2) Transaxle drive pulley

(3) Mower belt

(4) Electric clutch

(5) Clutch mounting bolt

4. Apply a light coating of copper-based anti-seize

lubricant to the engine crank shaft.

(1) Engine crank shaft

5. Reinstall the transaxle drive pulley, electric clutch,

and clutch mounting bolt.

6. Torque the clutch mounting bolt to 67-75 N

⋅

m

(50-55 lbf

⋅

ft).

7. Reinstall the transaxle belt.

8. Reinstall the mower belt.

EVERY 500 HOURS OR EVERY

1 YEAR

1. Adjusting the electric clutch

WARNING

To avoid serious injury or death:

• Park the machine on a firm and level surface.

• Apply the parking brake.

• Stop the engine and remove the key before

adjusting the electric clutch.

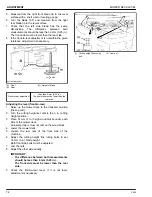

The electric clutch serves 2 functions in the operation

of the mower:

• Starting and stopping the power flow to the cutter

blades.

• The clutch also acts as a brake to assist in stopping

blade rotation when the PTO is switched off or the

operator presence control is interrupted.

When the clutch is disengaged, the air gap between the

armature and rotor must be adjusted to 0.4 mm

(0.015 in.) for proper operation. The air gap adjustment

is made with 3 bolts on the clutch. There are 3

inspection windows, one next to each adjusting bolt.

(1) Inspection window (x3)

(A) Electric clutch

1. Locate the inspection windows on the clutch.

PERIODIC SERVICE

EVERY 500 HOURS

66

Z400

Summary of Contents for Z411

Page 3: ...OPERATOR S MANUAL 1SFRT00108A01 READ AND SAVE THIS MANUAL MODELS Z411 Z421 Z421T ...

Page 9: ...4 Z400 ...

Page 16: ...SAFETY LABELS SAFE OPERATION Z400 11 ...

Page 17: ...SAFE OPERATION 12 Z400 ...

Page 18: ...SAFE OPERATION Z400 13 ...

Page 19: ...SAFE OPERATION 14 Z400 ...

Page 20: ...SAFE OPERATION Z400 15 ...

Page 53: ...PERIODIC SERVICE CHART LABEL MAINTENANCE PERIODIC SERVICE CHART LABEL 48 Z400 ...