43

PERIODIC SERVICE

ENGLISH

B

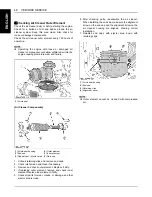

Checking Transaxle Fluid Level

1. Park the machine on a flat surface, lower the

implement to the ground and shut off the engine and

remove the key.

2. Check to see that the oil level lies between the "MAX"

and "MIN" lines while the machine and oil are at

ambient temperature.

If the level is too low, add the new oil to the prescribed

level into the expansion tank.

(See "LUBRICANTS AND FUEL" in "MAINTENANCE"

section.)

3. Do not overfill past "MAX" line.

Oil expands with heat and may leak from cap during

usage if overfilled.

A

If oil level is low, do not run engine.

Add the new oil to the prescribed level into the

expansion tank.

A

Do not overfill the expansion tank.

B

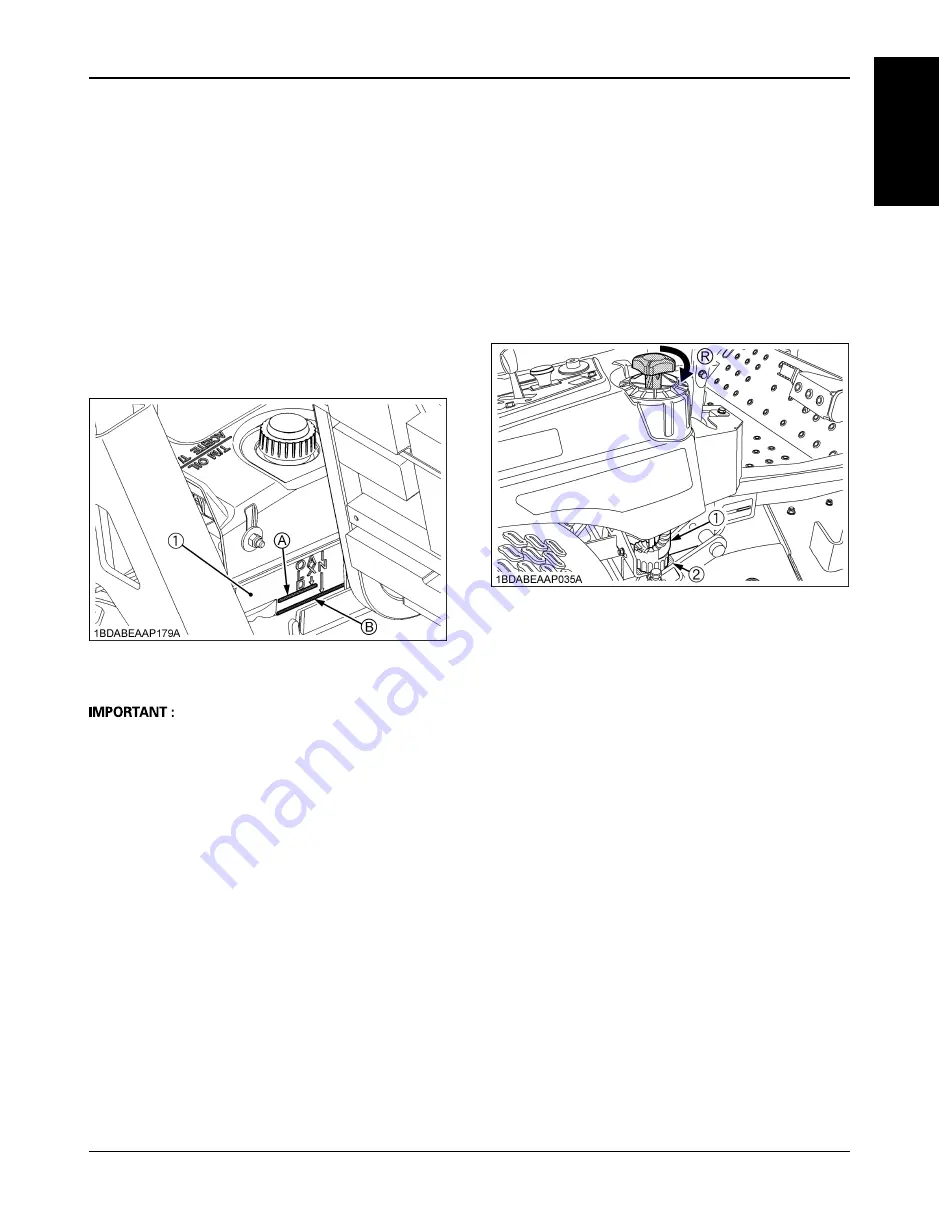

Checking Dial Cam Rotation Force

1. Park the machine on a flat surface, shut off the engine

and remove the key.

2. Raise the implement to the "TRANSPORT" position.

(See "ADJUSTING CUTTING HEIGHT" in

"OPERATING THE MOWER" section.)

3. Rotate the cutting height control dial and check for

smoothness.

4. If rotation force is too high, clean dial cam area and

apply grease under the dial cam between the dial cam

and frame.

B

Checking Movable Parts

If any of the movable parts, such as levers and pedals, is

not smoothly moved because of rust or sticky material, do

not attempt to force it into motion.

In the above case, remove the rust or the sticky material,

and apply oil or grease on the relevant spot.

Otherwise, the machine may get damaged.

(1) Transaxle fluid expansion tank

(A) MAX line

(B) MIN line

(1) Dial cam

(2) Frame surface

(R) "ROTATE"

Summary of Contents for Z724X

Page 7: ...CONTENTS ENGLISH INDEX 79 ...

Page 13: ...SAFE OPERATION 6 ENGLISH 5 DANGER WARNING AND CAUTION LABELS ...

Page 14: ... 7 SAFE OPERATION ENGLISH ...

Page 15: ...SAFE OPERATION 8 ENGLISH ...

Page 16: ... 9 SAFE OPERATION ENGLISH ...

Page 19: ...SERVICING OF MACHINE 2 ENGLISH 1 ROPS serial No ...