59

PERIODIC SERVICE

ENGLISH

C

Purging Procedure

Before starting, make sure the transaxle is at the

proper oil level. If it is not, fill to the specifications

outlined in this manual.

The following procedures are best performed with the

machine drive wheels off the ground, and then

repeated under normal operating conditions. If this is

not possible, perform this procedure in an open flat

area free of any objects or bystanders.

1. Open the bypass valves of both transaxles with the

bypass levers. (See "Hydrostatic Transaxle Bypass

Lever" in "OPERATING THE MACHINE" section.)

2. Start the engine and disengage the parking brake.

3. Set the engine throttle to low idle.

4. Slowly move the motion control levers to the max

forward position. Hold for 30 seconds.

5. Slowly move the motion control levers to the max

reverse position. Hold for 30 seconds.

6. Place the motion control levers in neutral lock and

apply the parking brake.

7. Close the bypass valves of both transaxles.

8. Set the engine throttle to high idle.

9. Disengage the parking brake.

10. Slowly move the motion control levers to the max

forward position. Hold for 30 seconds.

11. Slowly move the motion control levers to the max

reverse position. Hold for 30 seconds.

12. Place the motion control levers in neutral lock, apply

the parking brake, and stop the engine.

13. Check the transaxle oil level. If oil level is below the

"MIN" line, proceed to step 14. Otherwise, the purging

process is complete.

14. Loosen breather port plug by 3 turns.

15. Fill expansion tank with new oil and allow oil to drain

into transaxle. Continue until oil just comes out from

the breather port plug.

16. Tighten the breather port plug. Torque to 11.3-13.5 N-

m (8.34-9.95 lbf-ft).

17. Continue to fill the transaxle through the expansion

tank until the "MAX" line is reached on the expansion

tank. (See "Checking Transaxle Fluid Level" in "DAILY

CHECK" in "PERIODIC SERVICE" section.)

18. Repeat steps 1 through 13 until all air is purged from

the transaxles.

B

Changing Transaxle Fluid

(See "Replacing Transaxle Oil Filter Cartridge" in "EVERY

500 HOURS AFTER 300 HOURS" in "PERIODIC

SERVICE" section.)

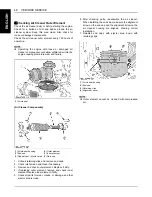

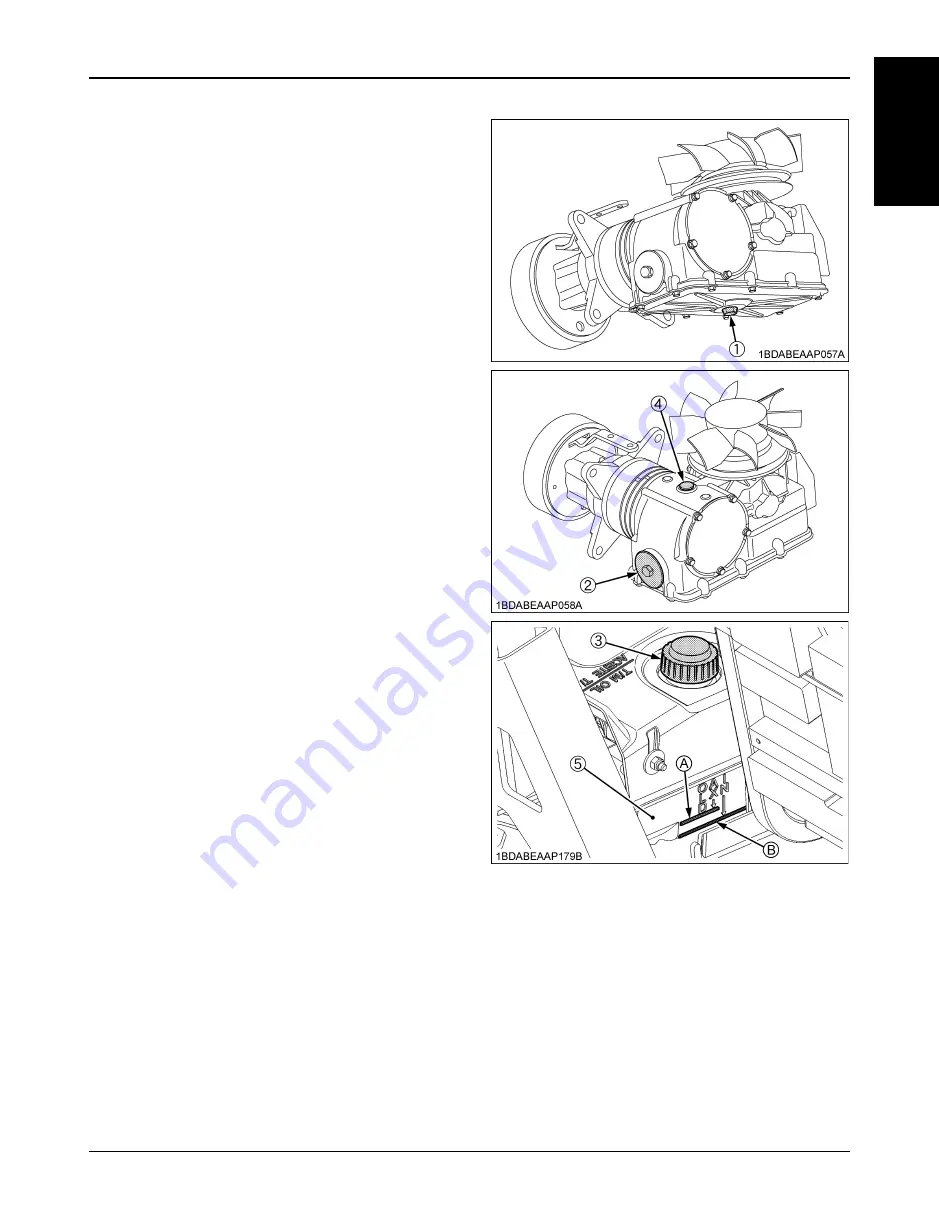

(1) Oil drain plug

(2) Oil filter

(3) Oil tank cap

(4) Breather port plug

(5) Transaxle fluid expansion tank

(A) MAX line

(B) MIN line

Summary of Contents for Z724X

Page 7: ...CONTENTS ENGLISH INDEX 79 ...

Page 13: ...SAFE OPERATION 6 ENGLISH 5 DANGER WARNING AND CAUTION LABELS ...

Page 14: ... 7 SAFE OPERATION ENGLISH ...

Page 15: ...SAFE OPERATION 8 ENGLISH ...

Page 16: ... 9 SAFE OPERATION ENGLISH ...

Page 19: ...SERVICING OF MACHINE 2 ENGLISH 1 ROPS serial No ...