55

MAINTENANCE

EVERY 100 HOURS

B

Cleaning Air Cleaner Primary Element

To avoid serious injury or death:

A

Be sure to stop engine and remove the key

before cleaning air cleaner element.

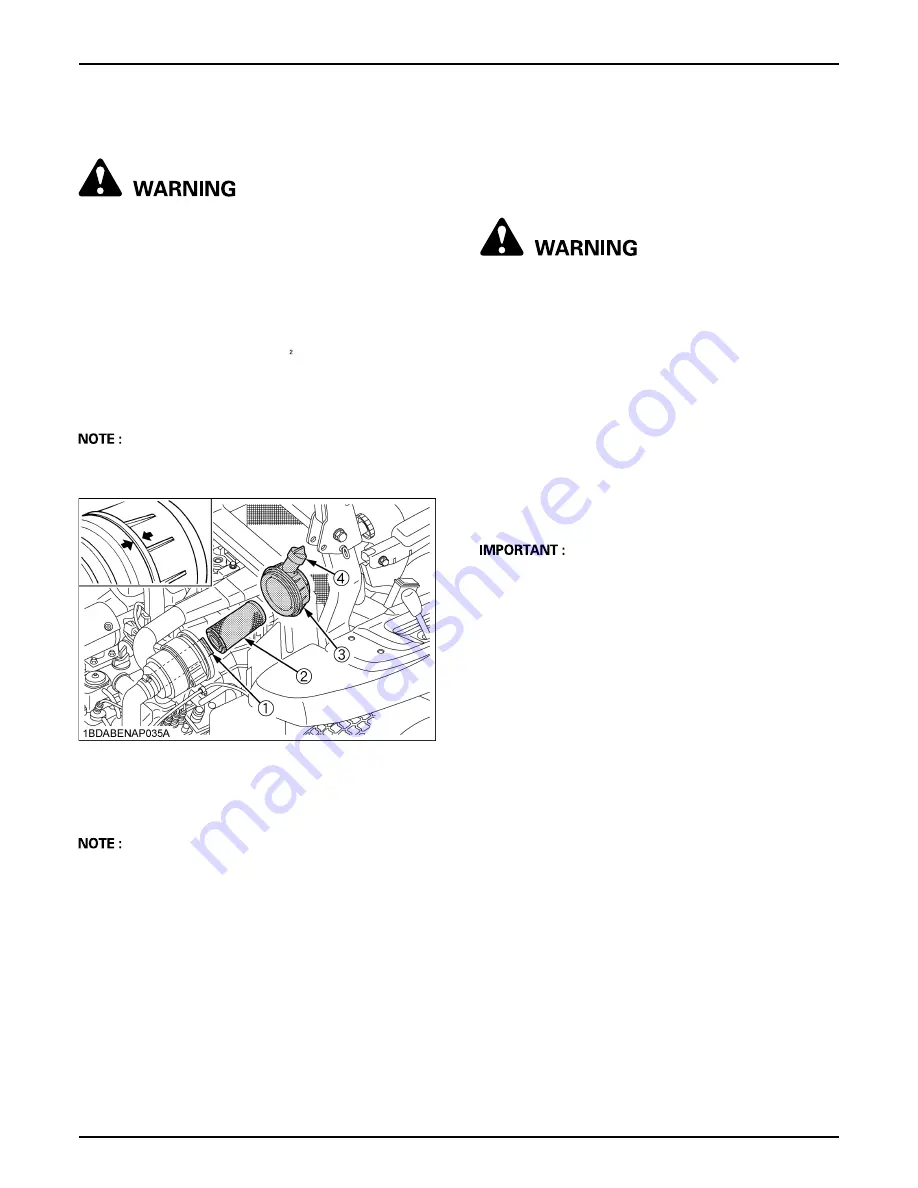

1. Remove the air cleaner cover and primary element.

2. Clean the primary element:

A

When dry dust adheres to the element, blow

compressed air from the inside, turning the

element. Pressure of compressed air must be

under 205 kPa (2.1 kgf/cm , 30 psi).

3. Replace air cleaner primary element:

Once yearly or every 1000 hours whichever comes

first.

A

Check to see if the evacuator valve is blocked with

dust.

A

The air cleaner uses a dry element, never apply oil.

A

Do not run the engine with filter element removed.

A

Operating in dusty conditions requires more frequent

maintenance.

A

Align the arrow marks when reinstalling the air cleaner

cover.

A

Do not touch the secondary element except in cases

where replacing is required.

(See "Replacing Air Cleaner Primary Element and

Secondary Element" in "EVERY 1000 HOURS or

EVERY 1 YEAR" in "MAINTENANCE" section.)

C

Evacuator Valve

Open the evacuator valve once a week under ordinary

conditions - or daily when used in a dusty place - to get rid

of large particles of dust and dirt.

B

Checking Fuel Filter

To avoid serious injury or death:

A

Be sure to stop the engine and remove the key

when attempting to make the following checks

and changes.

A

Never fail to check the fuel lines periodically.

The fuel lines are subject to wear and aging.

Fuel may leak out onto the running engine,

causing a fire.

1. Open the hood.

2. The fuel line is made of rubber and ages regardless of

service period.

3. If the fuel line and clamps are found damaged or

deteriorated, replace them.

4. Check fuel filter, if it is clogged by debris or

contaminated with water, replace it.

A

When the fuel line is disconnected for maintenance or

repair, close both ends of the fuel line with a piece of

clean cloth or paper to prevent dust and dirt from

entering. In addition, particular care must be taken not

to admit dust and dirt into the fuel pump. Entrance of

even a small amount dust or dirt cause premature

wear and malfunction of the fuel pump and injector

components.

(1) Secondary element

(2) Primary element

(3) Cover

(4) Evacuator valve

Summary of Contents for ZD1011-AU

Page 15: ...SAFE OPERATION 8 7 DANGER WARNING AND CAUTION LABELS ...

Page 16: ... 9 SAFE OPERATION ...

Page 17: ...SAFE OPERATION 10 ...

Page 18: ... 11 SAFE OPERATION ...

Page 21: ...SERVICING OF MACHINE 2 1 ROPS serial number ...

Page 69: ...50 MAINTENANCE PERIODIC SERVICE CHART LABEL 1 Part No K3411 6552 5 ...