PERIODIC SERVICE

42

ENGLISH

B

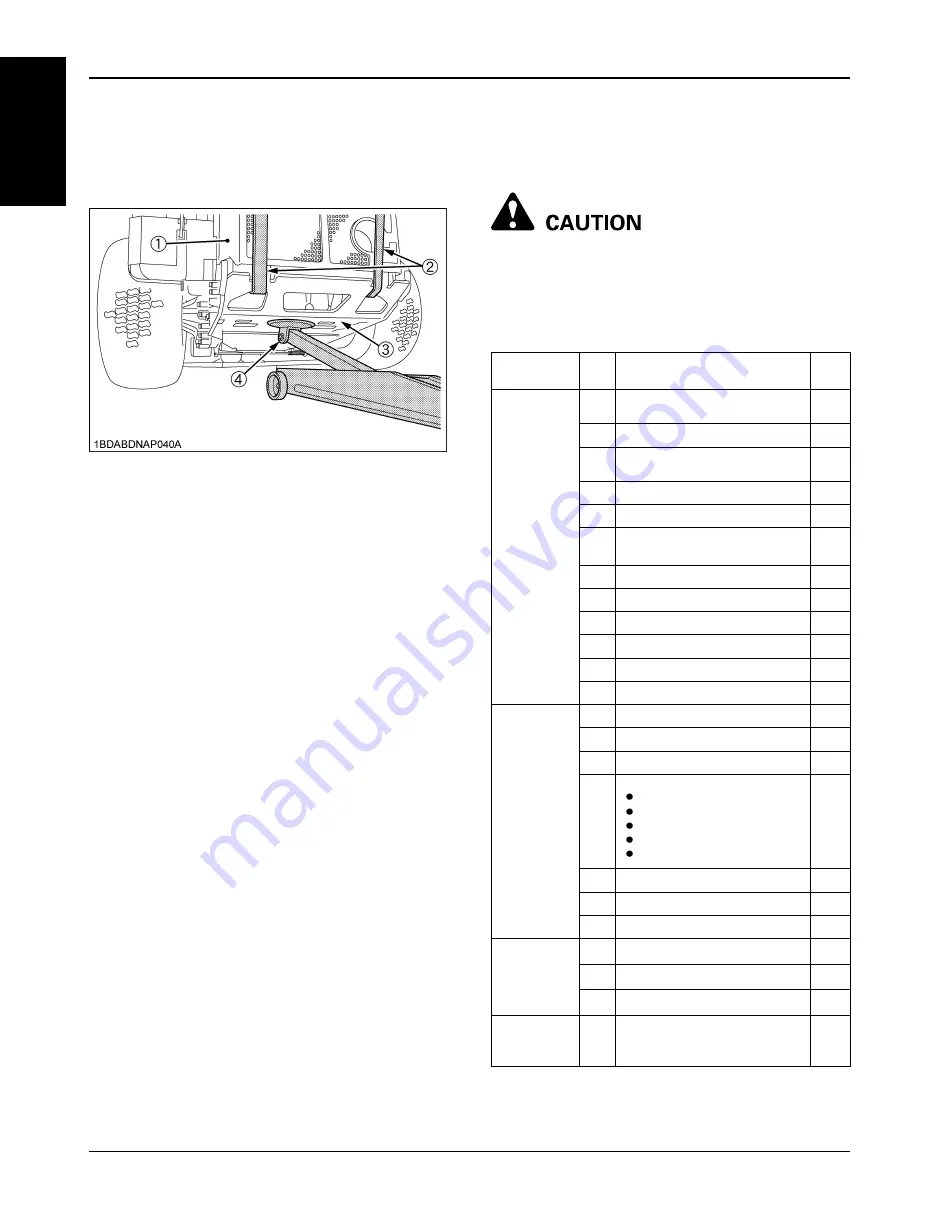

Rear side:

Hoist the rear frame with nylon slings. Or jack up the

bottom plate.

DAILY CHECK

To prevent trouble from occurring, it is important to know

the condition of the machine. Check it before starting.

To avoid personal injury:

A

Be sure to check and service the machine on a

level surface with the engine shut off, the key

removed and the parking brake securely set or

chock the rear wheels.

(1) Rear frame

(2) Nylon sling

(3) Bottom plate

(4) Jack

No.

Check item

Ref.

Page

Walking

around the

machine

1

Damage of machine body, tightness

of all bolts, nuts and pins, etc.

-

2

Fuel and oil leak

-

3

Tire pressure, wear and damage

4

Engine oil level

5

Fuel level

6

Air intake screen, engine cooling

area

7

Transmission fluid level

8

Greasing

9

Brake play

10

Air cleaner primary element

11

Bottom dust cover

12

Machine body cleaning

-

Mower

1

Check all hardware.

-

2

Make sure all pins are in place

-

3

Mower deck cleaning

-

4

Greasing

Universal joint

Three spindle shafts

Belt tension pulley

Belt tension pivot

Anti-scalp roller

5

Oil leak

6

Make sure blade bolts are tight

7

Blades and belt wear or damage

While sitting in

the operator's

seat

1

Motion control lever

-

2

Parking brake

-

3

Other movable parts

Turning the

key switch

"ON"

1

Performance of the Easy

Checker(TM) light

Summary of Contents for ZG222A

Page 3: ...1BDABDNAP0010 OPERATOR S MANUAL READ AND SAVE THIS MANUAL MODELS ENGLISH ZG222A ZG227A ...

Page 16: ...SAFE OPERATION 6 ENGLISH 7 DANGER WARNING AND CAUTION LABELS ...

Page 17: ... 7 SAFE OPERATION ENGLISH ...

Page 18: ...SAFE OPERATION 8 ENGLISH ...

Page 19: ... 9 SAFE OPERATION ENGLISH ...