25

OPERATING THE MACHINE

WORK LIGHT (OPTIONAL KIT)

STOPPING

To avoid personal injury:

A

Park the machine on level ground.

If necessary to park on an incline,

(1) Stop the machine,

(2) Apply the parking brake, then

(3) Stop the engine.

A

If you stop the engine on an incline without

applying the parking brake, the machine could

move and run away.

A

The parking brake pedal is for parking and emergency

use only. If the parking brake is applied when the

motion control levers are not in "NEUTRAL LOCK"

position, the engine will stop within approximately 3

seconds. This feature is to prevent brake and

transmission damage during operation.

1. Move both motion control levers to the "NEUTRAL"

position to stop the machine.

2. Apply parking brake.

3. Move both motion control levers to "NEUTRAL LOCK"

position.

4. Move the throttle lever to the half speed position and

shift PTO lever to the "DISENGAGE" (OFF) position.

5. Lower all implements to the ground.

6. Turn off the engine and remove the key.

A

Do not stop the engine when the machine is on an

incline for a long time. The engine oil may go into the

carburetor and the muffler through the valve system.

A

Place the throttle control lever in the half speed

position to help prevent the engine from backfiring

before stopping the engine.

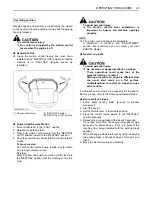

PARKING

TO LOCK:

Depress the parking brake pedal firmly with your right

foot, and the parking brake lock pedal simultaneously

with your left foot. Then release the parking brake

pedal while holding the parking brake lock pedal down.

TO UNLOCK:

Depress the parking brake pedal and release slowly

with your right foot, without pressing the parking brake

lock pedal.

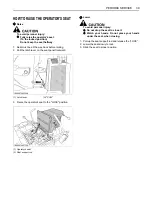

To avoid personal injury:

Before leaving the operator's position,

A

Apply parking brake.

A

Lower all implements to the ground.

A

Shut off the engine.

A

Remove the key.

A

Place the motion control levers in the

"NEUTRAL LOCK" position.

If necessary to park on an incline, be sure to chock the

wheels on the downhill side to prevent accidental rolling of

the machine.

(1) Work light

(1) Chocks

Summary of Contents for ZG327A-AU

Page 13: ...SAFE OPERATION 6 7 DANGER WARNING AND CAUTION LABELS ...

Page 14: ...7 SAFE OPERATION ...

Page 15: ...SAFE OPERATION 8 ...

Page 17: ......

Page 52: ...35 MAINTENANCE PERIODIC SERVICE CHART LABEL 1 Part No K3287 6552 ENGLISH ...