3

Issue 01 MAR.19

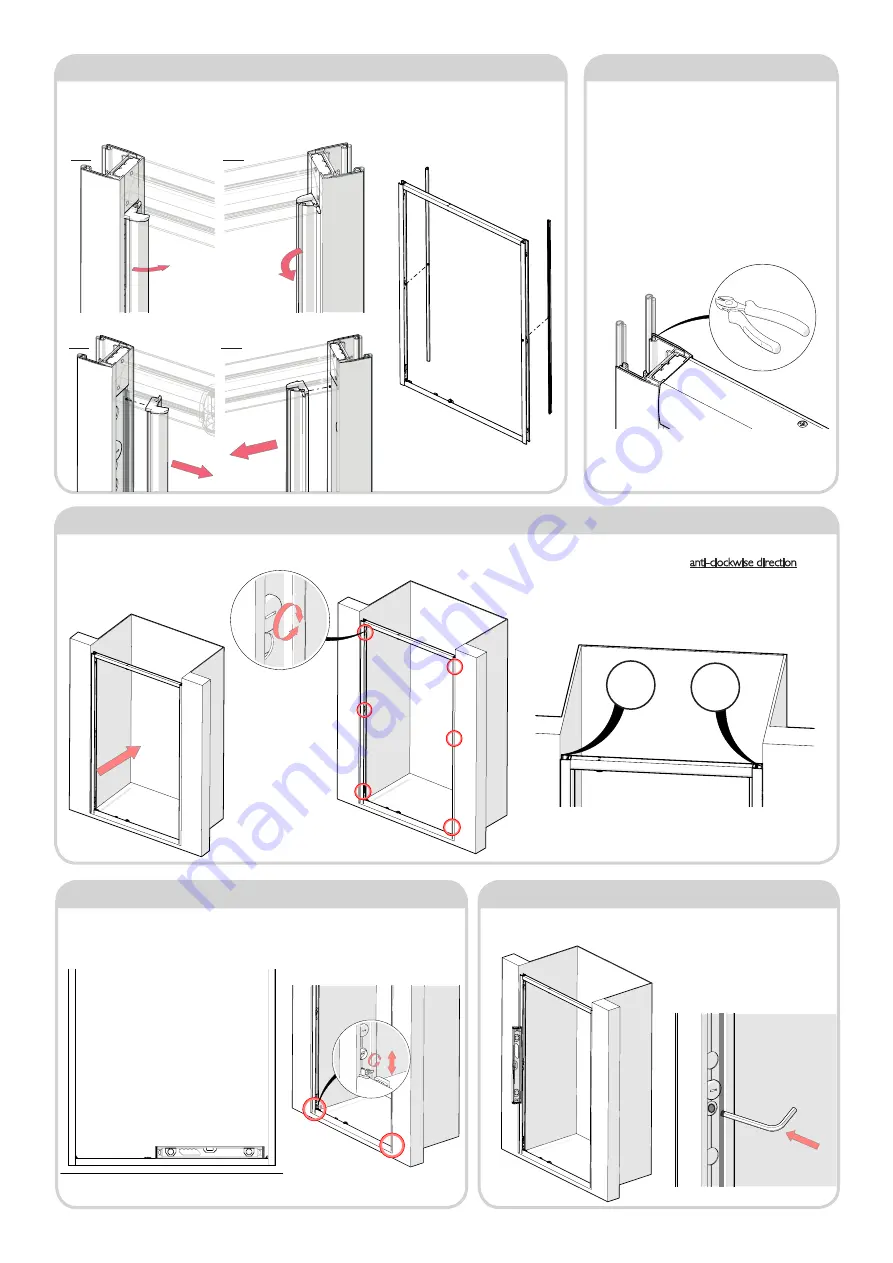

Step 6 - Trim Excess Seal

1.During the manufacturing process the seals on

each side of the frame are often left ‘long’ to allow for

expansion and contraction during transit. Ensure the

seals are sitting flush with the bottom of the frame on

each side.

2.Using cutting pliers, trim the seals on each side flush

with the top of the frame.

Step 5 - Remove Clip-In Extrusions

1. Locate the clip-in extrusions down the in side of the

frame, press and rotate the clip-in extrusion at top, middle

and bottom of door frame, to gently prise the extrusion

away from the frame by hand only.

2. Remove the clip-in extrusion from each side of the frame.

LHS

LHS

RHS

RHS

3. Ensure the removed extrusions are

kept separate, as left and right.

2. Using a flat headed screwdriver, adjust the six nylon adjustment

screws, three down each side, in an anti-clockwise direction, until

the frame has expanded and is only slightly wedged. Try to adjust

each side equally, to achieve equal spacings down each side of the

frame .

=

=

Step 8 - Adjust Height

1. Using a spirit level, check to see if

the bottom frame is level, ensure the

spirit level is sat down fully onto the sill.

2. Using a flat-head screwdriver adjust the

two nylon height adjustment screws (lower

screw in each corner). Adjust until the

bottom frame is level.

Step 9 - Mark Position of Holes

1. Using a spirit level, check that the

frame ‘plumb’ vertical.

2. Using a 4mm rod (we recommend

a small Allen key or drill bit), place a

small amount of marking paste (we

recommend shoe polish) on the end

of the rod, and ‘spot’ through the 3

screw holes down each side of the

frame (blue lined).

Step 7 - Offer Up & Adjust Fit

1. ‘Offer up’ the frame into the recess,

ensuring the bottom is sat firmly on the

shower tray.