7

Issue 01 MAR.19

SILICONE ALONG SHIM ONLY

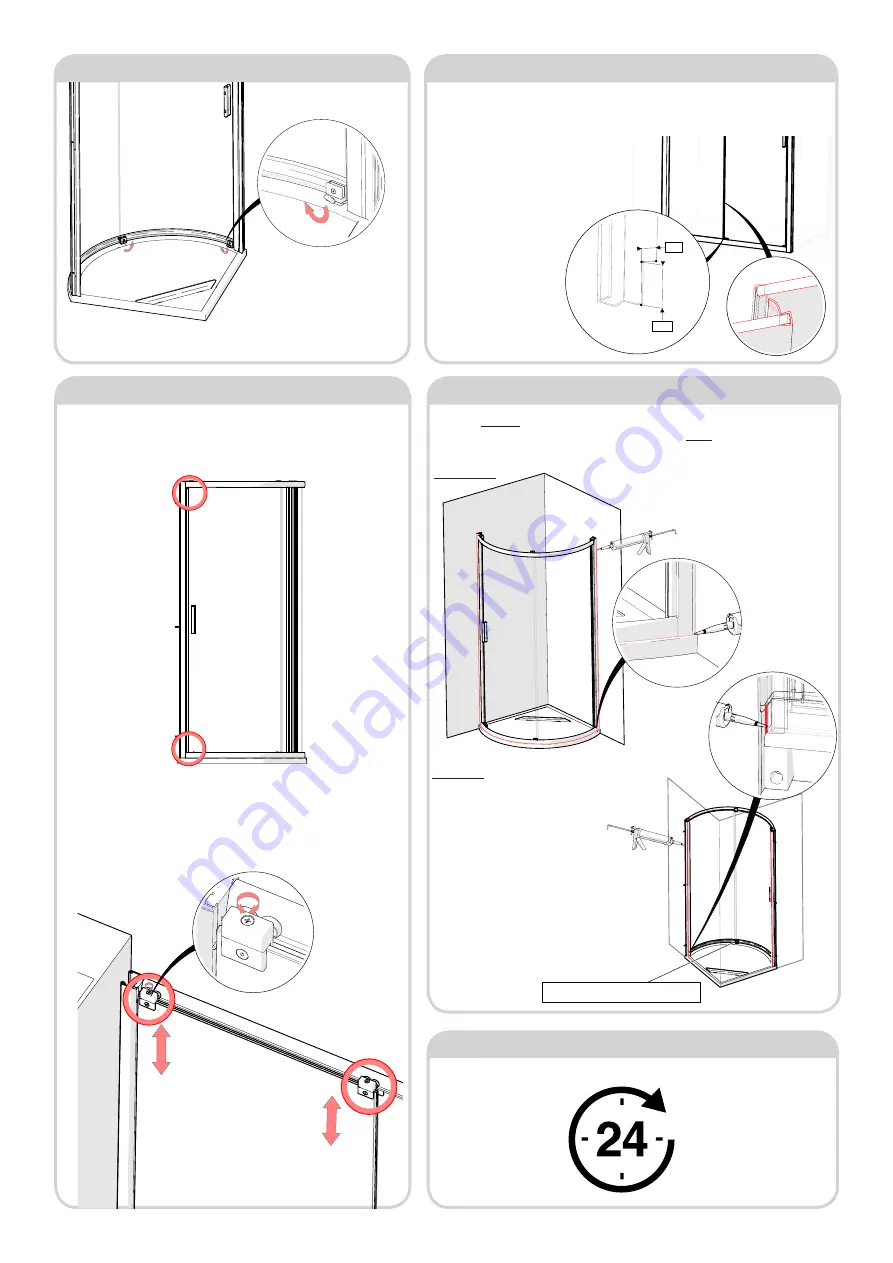

1.Looking from the outside of the enclosure, slide the door into the

closed position, with the glass pushed up against the wall post. Check

the door glass is level with the wall post down the entirety of its edge.

2.If there is an uneven gap, the glass in the door can be adjusted either

up or down at each corner with the rollers. Using ozi-head Screwdriver,

loosen or tighten the bolt located on the top of each roller set. Each

roller has around 6mm of adjustment, clockwise will lower the glass,

anti-clockwise raises the glass.

Step 22 - Adjust Glass

1. On the

outside, silicone around all three junctions with the wall and tray, and also

on the frame where the sill meets the uprights. On the

inside, only silicone along the

two vertical junctions with the wall, and around the shim.

Step 24 - Silicone

Outside Only

Inside Only

Step 25 - Wait 24hr

1. Allow 24 hours before using the shower.

Do not silicone seal on the inside of

unit (except where shown). Sealing

the wall posts & sills to the tray on the

inside can result in leakage problems-

please note that, in use, water can

penetrate into the frame extrusions-

this has no detrimental effect to the

product- however, this water must be

allowed to drain out of the extrusions

to the inside. Silicone down the wall

posts wall junction, around the shim

and at the bottom between the fixed

glass seal and wall post.

2. Turn the two release levers, until

the slots in the rear arms of the

release levers sits onto the bottom

rail edge protrusion, holding the

bottom of the door in-place.

Step 21 - Fit Glass Door (continued)

Step 23 - Fit Overlap Seals

16mm

5mm

Bottom Notch

Cut

1. Take the ‘1873 Overlap Seal’ (PlexRF023), and fit to the edge of the fixed panel,

with the soft ‘skirt’ facing the inside, in order to contact with the sliding door glass.

Make sure the seal is fully sat fully down onto the glass clamp at the bottom of the

fixed panel.

2. Fit the 1912mm Overlap

Seal (PlexRF023) to the

inside edge of the sliding

door glass panel, with the

soft fin facing the fixed panel.

Notch the top and bottom

(approximately 16mm at

the bottom, and 25mm at

the top), to ensure a tight

contact with the glass clamp

at the bottom when in the

closed position.