-14-

21

24

19

26

POSITION OF

GEARS

1st 2nd 1st 2nd 1st 2nd 1st

2nd

24

21

26

19

Standard gear set

*

Recommended speeds

(rotational frequencies)

Works setting

PTO

SPEED

(ROTATIONAL

FREQUENCY)

1000 rpm

(min

-1

) 224 270

292 352 187* 225* 350 422

540 rpm

(min

-1

) - -

- 190 - - 189* 228*

Optional (21/24 teeth)

(Set No. 120 7710)

The gearbox is fitted with a rear PTO

shaft which turns at the same speed

(rotational frequency) as the tractor

drive shaft. This rear drive shaft

should not be used to drive a secondary

machine while the gearbox is in its

neutral position (due to the risk of

gearbox damage resulting from inefficient

oil circulation).

The rear PTO shaft (1 3/8" 6 spline

profil) should not be used to transmit

more than 37 kW (50 hp).

If the rear PTO shaft is not used, always put cover (E) in place.

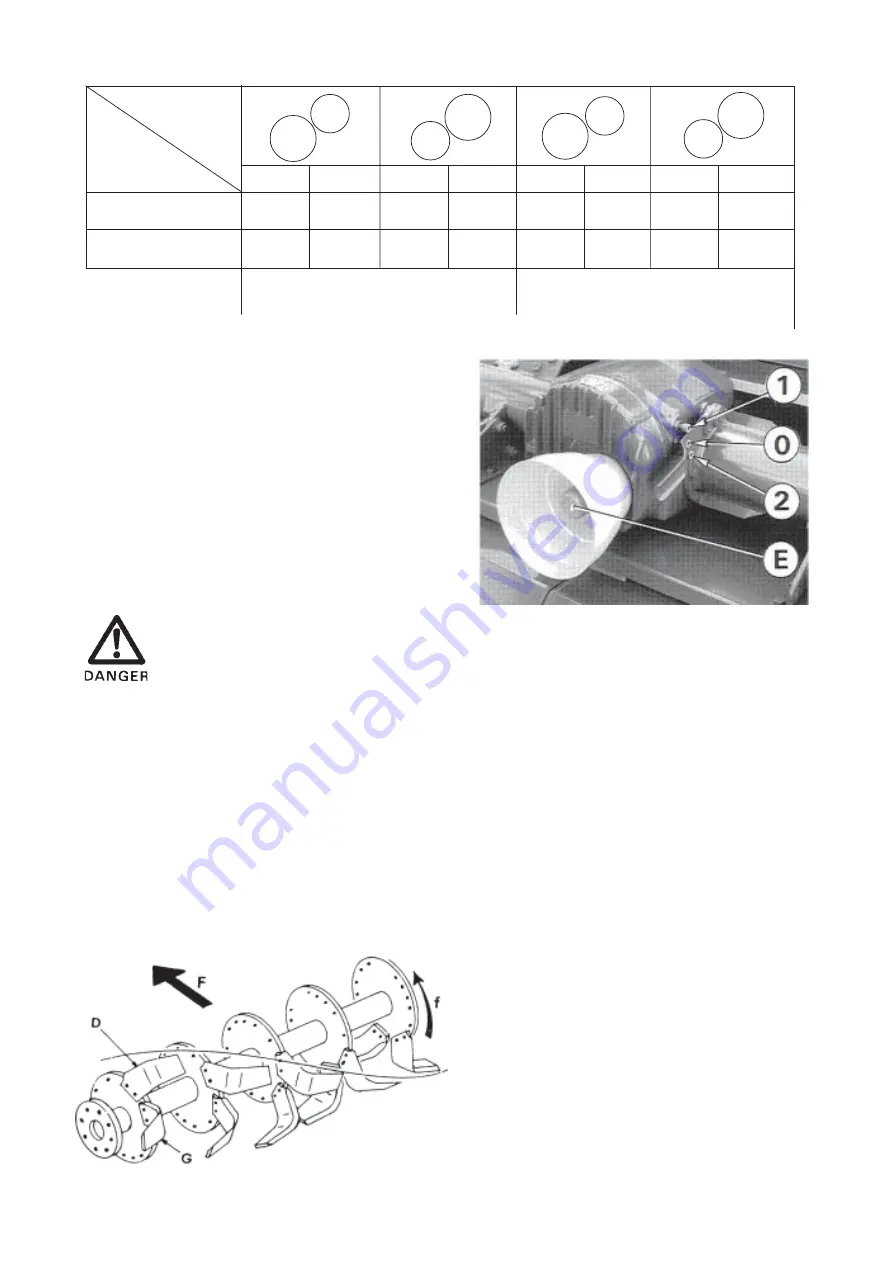

FITTING THE BLADES

1. STANDARD ROTOR

According to the type of work being carried out, the blades can be fitted in 2 ways:

- 3 pair formation (3 right D and 3 left G) as fitted at the factory.

- 2 pair formation (2 right D and 2 left G).

To recognise the difference between left-hand side and right-hand side blades, notice

that the cutting edge follows the direction (f) of rotation.

F = Forward direction

To fit blades helicordally, proceed as

follows :

- Always start the fitting on each flange

with the same type of blade and the same

place (opposite mark R page 12 which is

either a hollow or a chamfer).

- All blades are fitted on the left-hand

side of the flanges viewed from the rear.

Summary of Contents for EL 100 N

Page 1: ...ASSEMBLY OPERATOR S MANUAL EL 100 N POWER TILLER N 95458 A GB 12 1999...

Page 10: ...8...

Page 18: ...16...