- 23 -

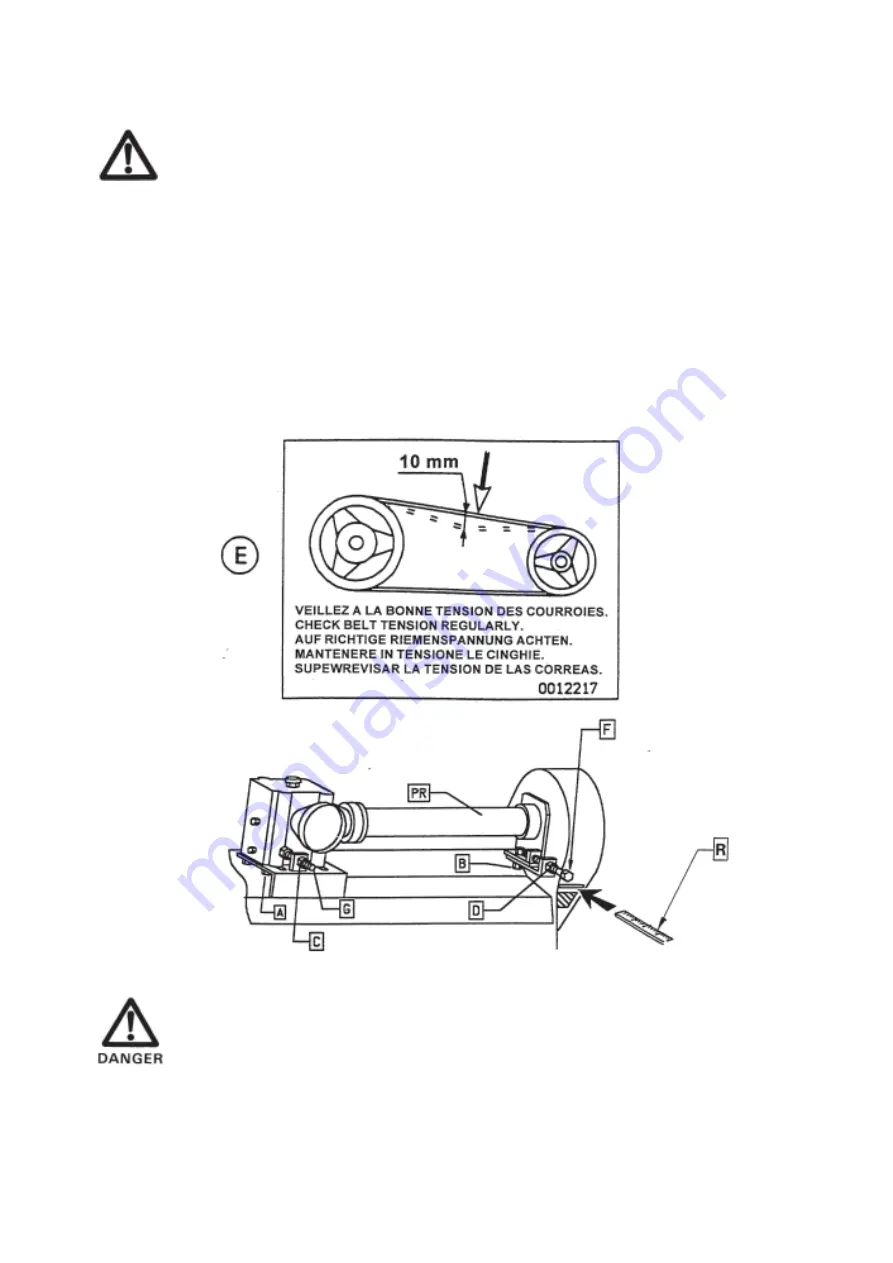

2° Belt Tension

Check belt tension regularly especially during the first hours of use.

The belt tension can be measured using a ruler scale (R ) placed through the hole in the hood.

Checking the belt tension

- Stop the tractor engine, remove ignition key and wait for all moving parts to stop before leaving the tractor

- Loosen screws (A) and (B) which fix the central casing to the frame of the machine.

- Loosen adjustment screw lock-nuts (C) and (D)

- Turn the screw (F) clockwise until the belts are correctly tightened. The belt is correctly tightened when a force

of 20 kilo gives a belt deflection of 10 mm/0.4" (see transfer)

- Adjust adjustment screw (G) by the same amount so that the central transmission shaft (PR) is parallel to the

machine rotor

- Retighten screws (A) and (B) as well as lock-nuts (C) and (D).

Checking the parallelism between the rotor axis and transmission shaft

Before adjusting, maintaining or repairing the machine, turn off the engine, remove ignition

key and wait until all moving parts have come to a complete stop.

- Remove the belt guard

- Place a ruler against the sides of the rotor pulley

- Slide the rotor pulley so that the ruler comes against the sides of the other pulley

- The ruler must be in contact with the 2 sides of the two pulleys. If not, screws (F) and (G) should be adjusted again

as well as the lock-nuts (C) and (D)

- Remount the belt guard.