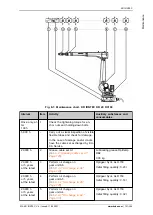

Fig. 7-8: Removing the fork slots

7.3.4

Connecting the connecting cables

Procedure

1. Fasten the ground conductor between the robot controller and the ro-

bot to the ground conductor connection with 1 M8 hexagon nut includ-

ing conical spring washer; tightening torque M

A

= 15.0 Nm.

2. Optionally, fasten the ground conductor between the system compo-

nent and the robot to the ground conductor connection with 1 M8 hex-

agon nut including conical spring washer; tightening torque

M

A

= 15.0 Nm.

3. Connect motor cable X30 and data cable X31 (

>>>

).

When connecting the motor and data cable connectors, it must be en-

sured that the connectors on the controller and on the robot are

locked correctly.

4. Check the equipotential bonding in accordance with VDE 0100 and

EN 60204-1.

Further information is contained in the operating and assembly in-

structions of the robot controller.

5. Enter the installation position of the robot in WorkVisual. The default

installation position is the floor.

KR IONTEC

182/344 |

www.kuka.com

MA KR IONTEC V4 | Issued: 11.05.2021

Start-up

and

recommissioning

Summary of Contents for IONTEC KR 20 R3100

Page 14: ...KR IONTEC 14 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Introduction...

Page 166: ...KR IONTEC 166 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Planning...

Page 188: ...KR IONTEC 188 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Start up and recommissioning...

Page 310: ...KR IONTEC 310 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Repair...

Page 340: ...KR IONTEC 340 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 KUKA Service...