3. Carry out a visual inspection of the cable jacket and clean it.

If damage is detected, the cable set must be exchanged.

4. Grease the hollow shaft sleeve and the cable jacket in the contact

area with a brush.

Protective gloves must be worn!

5. After checking and greasing the cable jacket and hollow shaft sleeve,

screw the cover plate onto the base frame and the rotating column.

8.2.2

Concluding work

The following concluding work must be carried out:

• Remove grease residue.

• To spread the grease out evenly, move A1 of the robot.

8.3

Oil change in A1

Description

The following sections describe the A1 gear oil change for floor-mounted

robots. For ceiling-mounted robots, the procedure is to be applied analo-

gously, but with the drain and filler holes reversed.

Equipment

The following equipment is required:

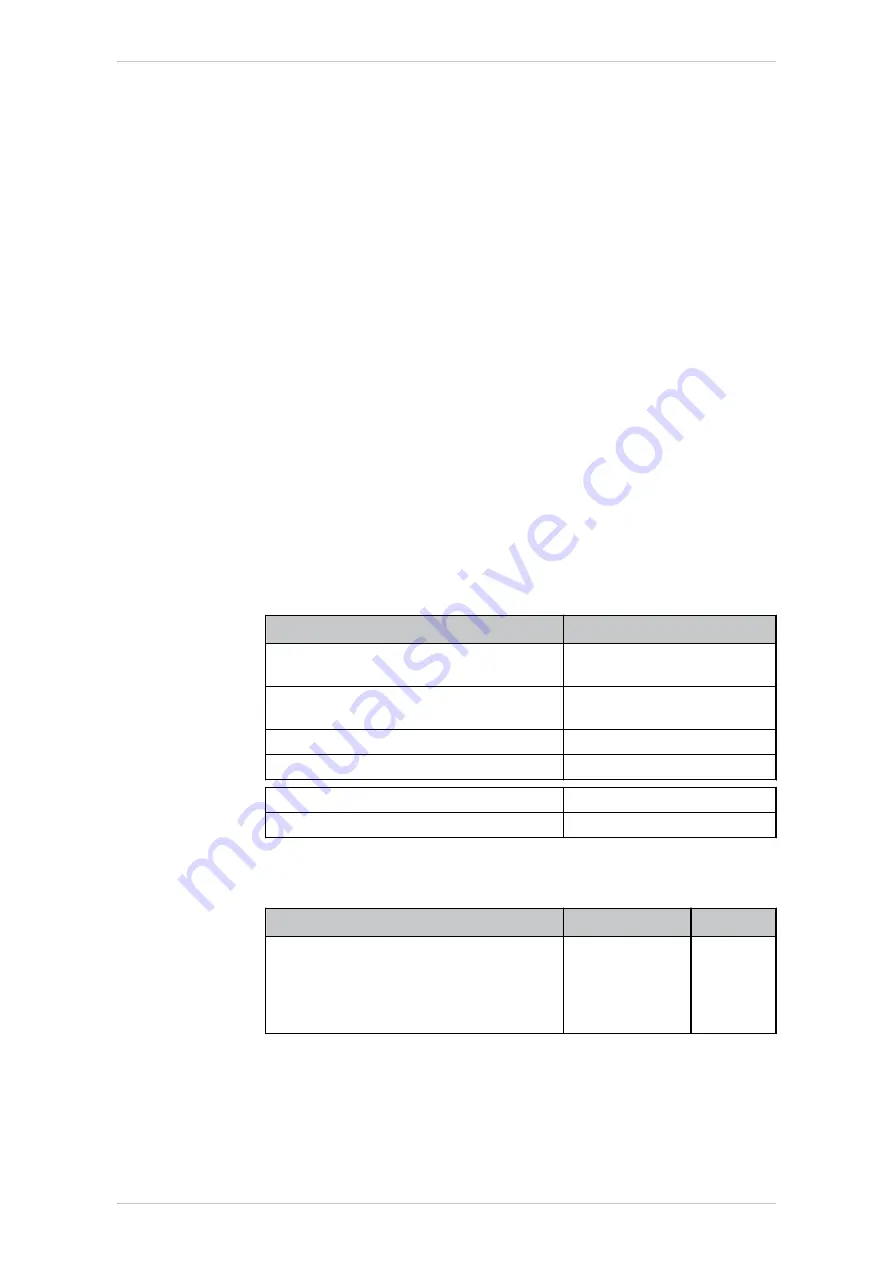

Designation

Article number

Set of Allen keys

1.5; 2; 2.5; 3; 4; 5; 6; 8; 10 mm

-

Torque wrench

min. 2 Nm to 30 Nm

-

Socket wrench set

-

Collection receptacle

-

KUKA oil pump

0000-180-812

Oil drain tube - M18x1.5

0000-265-680

Material

The following material is required:

Designation

Article number

Quantity

Optigear ALR 320

(

>>>

iliary and oper-

ating materials

used"

Page 336

)

Initial fill-

ing quan-

tity:5.66 l

Tightening torques

The tightening torques can be found under: (

>>>

)

These are valid for screws and nuts where no other specifications are giv-

en.

KR IONTEC

MA KR IONTEC V4 | Issued: 11.05.2021

www.kuka.com

| 197/344

Maintenance

Summary of Contents for IONTEC KR 20 R3100

Page 14: ...KR IONTEC 14 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Introduction...

Page 166: ...KR IONTEC 166 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Planning...

Page 188: ...KR IONTEC 188 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Start up and recommissioning...

Page 310: ...KR IONTEC 310 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Repair...

Page 340: ...KR IONTEC 340 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 KUKA Service...