Screws of strength class 10.9 and higher as well as screws with test cer-

tification may only be tightened once with the rated tightening torque.

When the screws are first slackened they must be replaced with new

ones.

Preconditions

• The gear unit is at operating temperature.

• All magnetic screw plugs for the oil chamber of gear unit A1 are freely

accessible.

Work safety

CAUTION

High oil and surface temperatures after the robot has stopped op-

erating

If the oil change is carried out immediately after the robot has stopped

operating, the oil temperature and the surface temperature are liable to

be high. Touching them may result in burns.

• Wear protective gloves.

WARNING

Danger to life and limb due to unintended robot motions

Unintended robot motions may result in death, severe injuries and dam-

age to property.

• Secure the robot by pressing the EMERGENCY STOP device.

• Warn all persons concerned before starting to put it back into opera-

tion.

8.3.1

Draining the gear oil from A1

Procedure

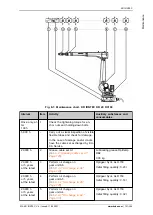

1. Place a suitable receptacle next to the oil drain hole (

>>>

ing the gear oil from A1" Page 198

).

2. Remove the M18x1.5 magnetic screw plug from the base frame and

screw on the oil drain tube.

3. Remove the M18x1.5 magnetic screw plug from the rotating column

for venting and catch the oil as it drains out.

4. Store or dispose of oil in accordance with the pertinent regulations.

KR IONTEC

198/344 |

www.kuka.com

MA KR IONTEC V4 | Issued: 11.05.2021

Maintenance

Summary of Contents for IONTEC KR 20 R3100

Page 14: ...KR IONTEC 14 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Introduction...

Page 166: ...KR IONTEC 166 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Planning...

Page 188: ...KR IONTEC 188 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Start up and recommissioning...

Page 310: ...KR IONTEC 310 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Repair...

Page 340: ...KR IONTEC 340 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 KUKA Service...