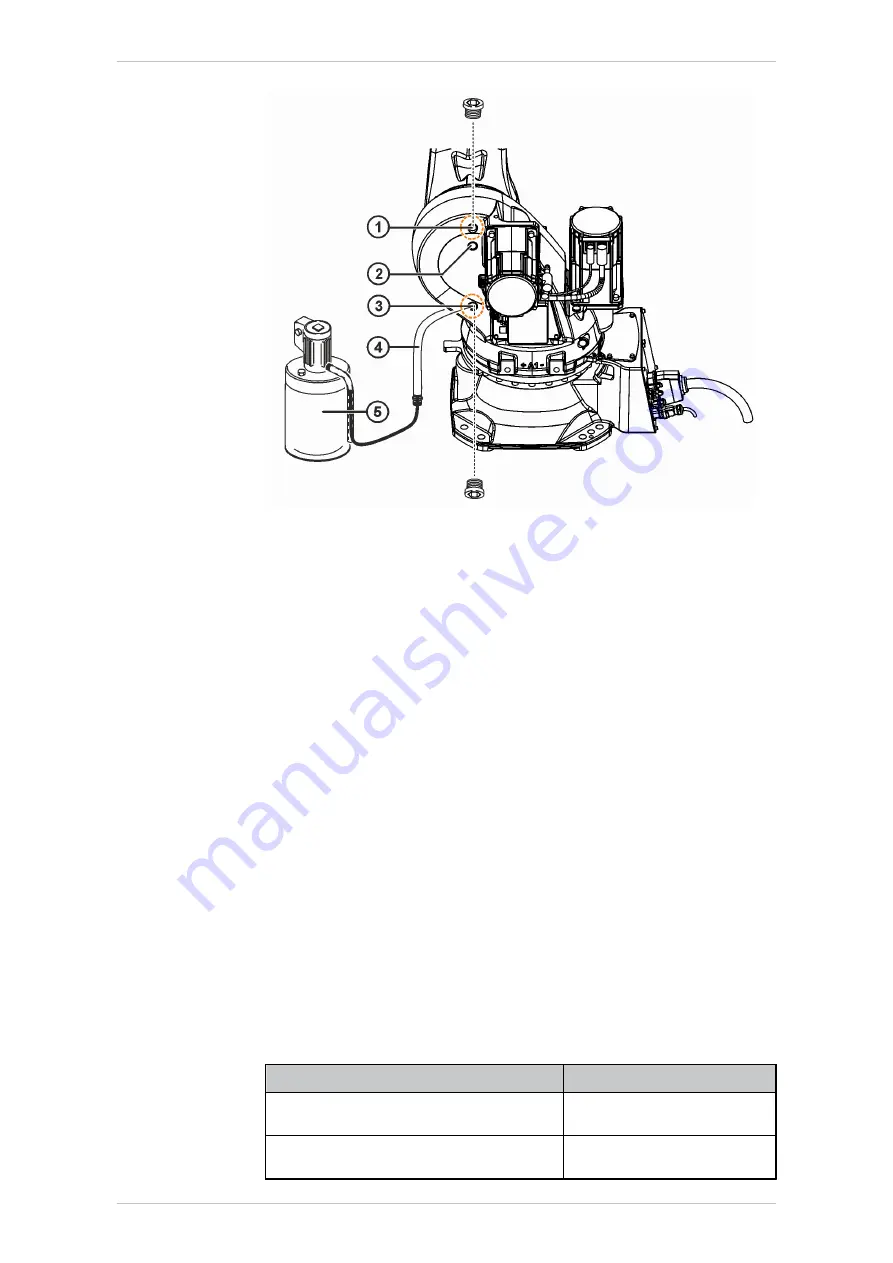

Fig. 8-7: Filling gear unit A2 with gear oil

1

M18x1.5 magnetic screw plug for venting

2

Inspection hole for floor installation

3

Oil drain hole with M18x1.5 magnetic screw plug

4

Oil drain pipe

5

Oil pump

8.4.3

Concluding work

The following concluding work must be carried out:

• Remove oil residue.

• Visual inspection, check for leaks.

• Run the program in T1 mode and look out for irregularities.

8.5

Oil change in A3

Description

The following sections describe the A3 gear oil change for floor-mounted

robots. For ceiling-mounted robots, the procedure is to be applied analo-

gously, but with the drain and filler holes reversed.

Equipment

The following equipment is required:

Designation

Article number

Set of Allen keys

1.5; 2; 2.5; 3; 4; 5; 6; 8; 10 mm

-

Torque wrench

min. 2 Nm to 30 Nm

-

KR IONTEC

MA KR IONTEC V4 | Issued: 11.05.2021

www.kuka.com

| 203/344

Maintenance

Summary of Contents for IONTEC KR 20 R3100

Page 14: ...KR IONTEC 14 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Introduction...

Page 166: ...KR IONTEC 166 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Planning...

Page 188: ...KR IONTEC 188 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Start up and recommissioning...

Page 310: ...KR IONTEC 310 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Repair...

Page 340: ...KR IONTEC 340 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 KUKA Service...