NOTICE

Wear and premature failure due to damage to toothing

Damage to the toothing of the motor and gear unit can lead to in-

creased wear and premature failure of the components.

• During cleaning, ensure that the toothing is not damaged.

• Before installation, check the toothing of the motor and gear unit for

damage.

9.2.1

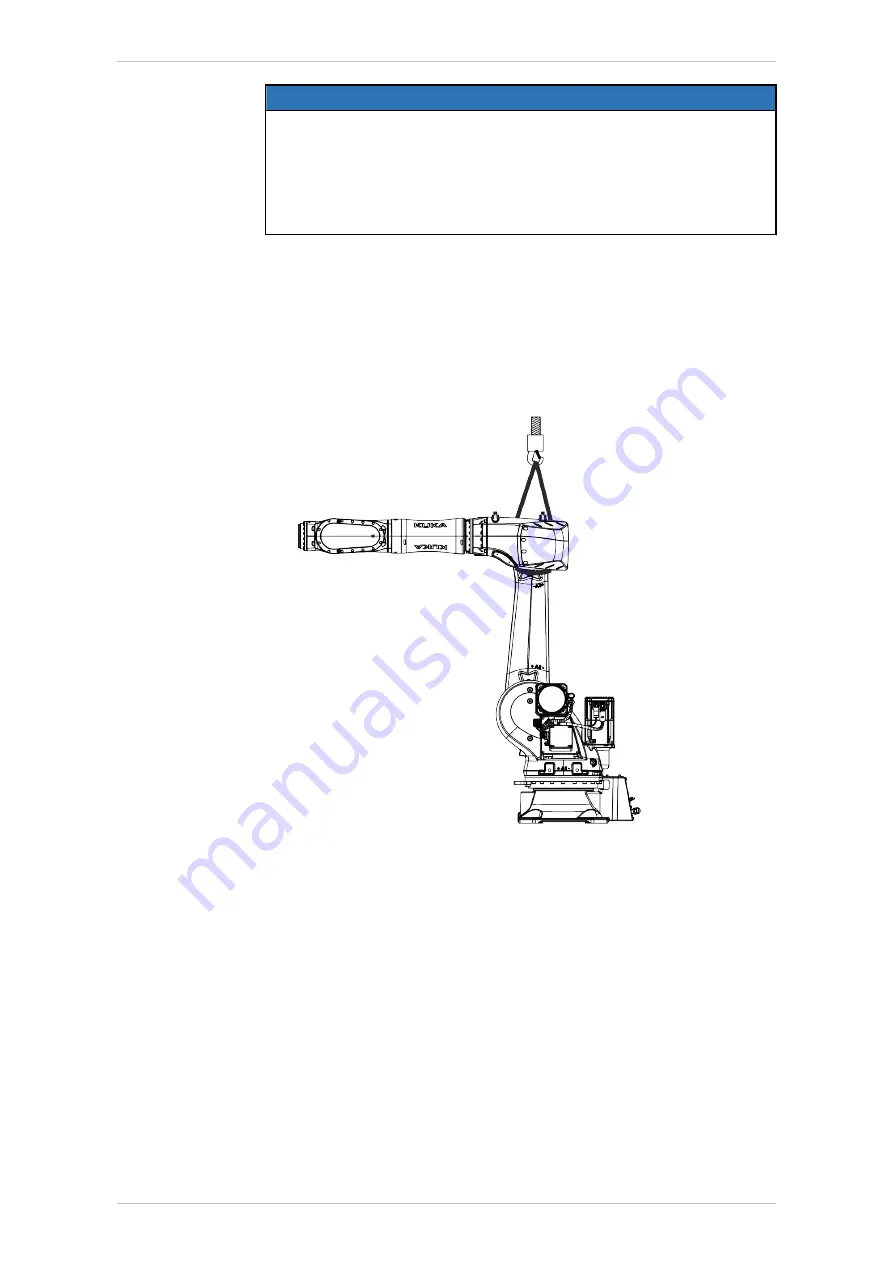

Securing the link arm

Procedure

1. Secure the link arm with a rope sling and attach the rope sling to the

crane hook.

2. Raise the rope sling until it is taut.

Fig. 9-3: Securing the link arm

9.2.2

Removing motor A2

Procedure

1. Release and unplug connectors XM2 and XP2 at the right-angle con-

nectors (

>>>

9.2.2 "Removing motor A2" Page 235

).

2. Unscrew 4 M10x25-8.8-A2K Allen screws.

3. Release and carefully lift out motor A2, taking care not to tilt it.

4. Cover the aperture on gear unit input shaft A2 and protect it against

fouling.

5. If the motor is not to be reinstalled, it must be disposed of properly or

protected against corrosion before being put into storage.

KR IONTEC

MA KR IONTEC V4 | Issued: 11.05.2021

www.kuka.com

| 235/344

Repair

Summary of Contents for IONTEC KR 20 R3100

Page 14: ...KR IONTEC 14 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Introduction...

Page 166: ...KR IONTEC 166 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Planning...

Page 188: ...KR IONTEC 188 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Start up and recommissioning...

Page 310: ...KR IONTEC 310 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Repair...

Page 340: ...KR IONTEC 340 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 KUKA Service...