7. Pull the sinuous spring off the motor.

8. If the motor is not to be reinstalled, it must be disposed of properly or

protected against corrosion before being put into storage.

9.5.3.4

Removing motor A5

Procedure

1. Unscrew 2 M6x12-8.8-A2K Allen screws each from both holders.

Mark the position of cable strap on the cable. Cut off the cable strap

at the first holder.

2. Remove holder from the robot arm.

Carefully cut off cable strap on plug-in connection A6 (far right) with

diagonal cutting pliers.

Remove plug-in connection A6 from the holder and disconnect it.

3. Unscrew 18 M6x35-8.8-A2K Allen screws between the in-line wrist

with arm extension and the arm.

Carefully pull the in-line wrist with arm extension a little way out.

4. Remove grounding from in-line wrist with arm extension. Release and

unplug connectors XM4/XP4 and XM5/XP5 at the right-angle connec-

tors.

5. Remove the in-line wrist with arm extension and set it down on a pre-

pared support.

6. Unscrew 4 M5x14-8.8 Allen screws from motor A5 and pull out the

motor. Do not tilt while removing.

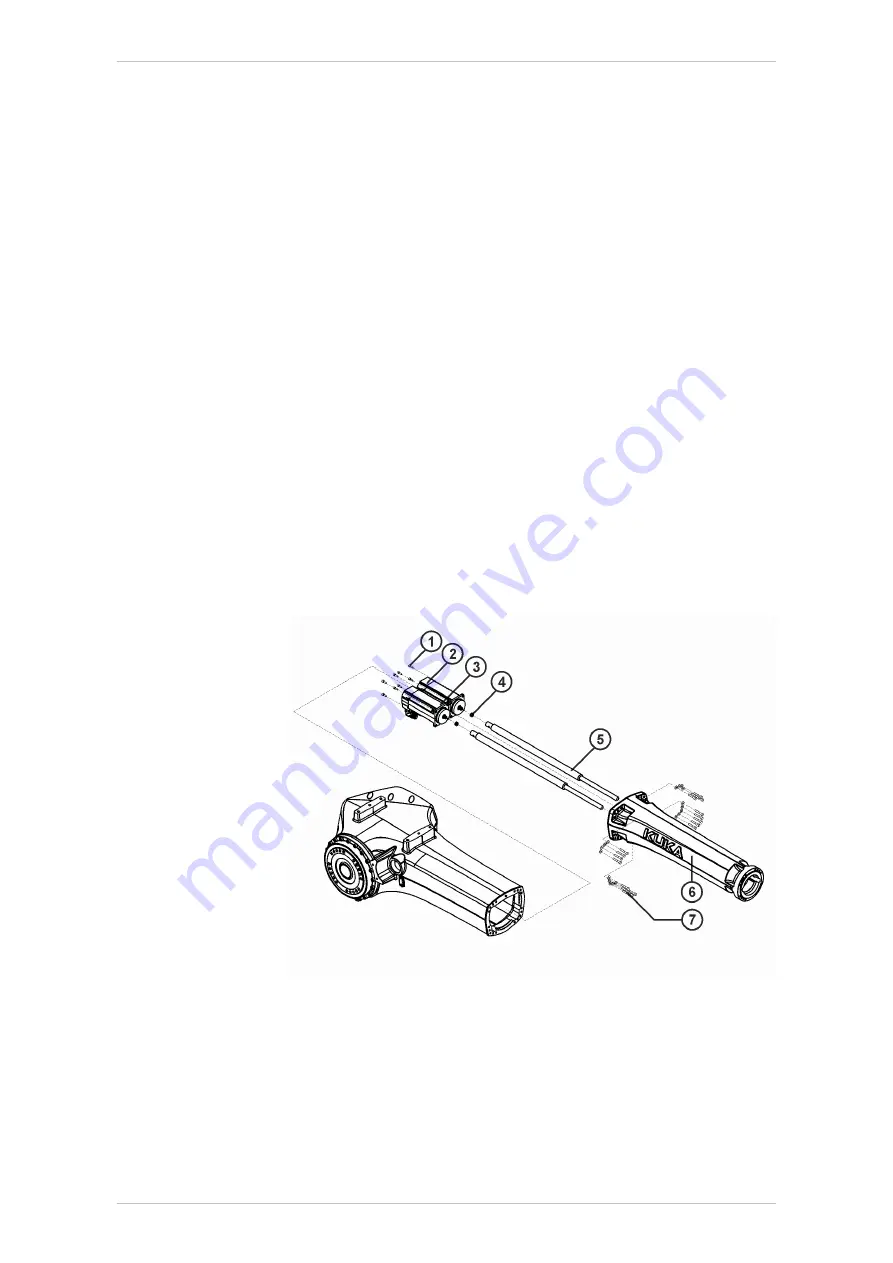

Fig. 9-36: KR 20 R3100 – Removing/installing motors A4 and A5

1

M5x14-8.8-A2K Allen screw (4x per motor)

2

Motor A4

3

Motor A5

4

Sinuous spring 0.25x11.43x15.88 (2x)

5

Connecting shaft R3100 (2x)

6

Arm extension

KR IONTEC

MA KR IONTEC V4 | Issued: 11.05.2021

www.kuka.com

| 277/344

Repair

Summary of Contents for IONTEC KR 20 R3100

Page 14: ...KR IONTEC 14 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Introduction...

Page 166: ...KR IONTEC 166 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Planning...

Page 188: ...KR IONTEC 188 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Start up and recommissioning...

Page 310: ...KR IONTEC 310 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Repair...

Page 340: ...KR IONTEC 340 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 KUKA Service...