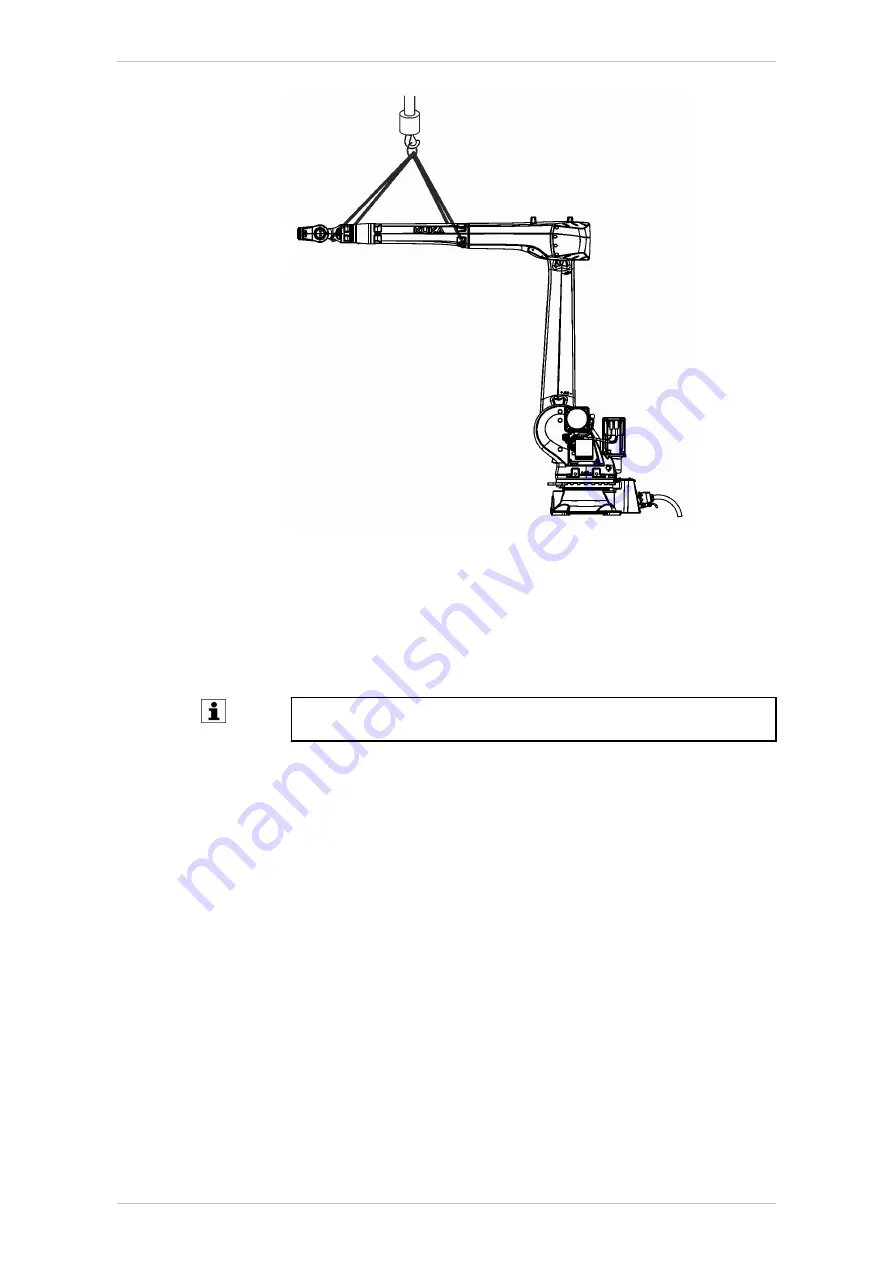

Fig. 9-54: Securing robot arm

9.5.4.9

Concluding work

The following concluding work must be carried out:

• Move A4, A5 and A6 of the robot and look out for irregularities.

• Carry out mastering of A4, A5 and A6.

Detailed information about mastering is contained in the operating

and programming instructions for end users or system integrators.

• Test the program in Manual Reduced Velocity mode (T1).

9.6

Description of the electrical installations

Overview

The electrical installations of the robot consist of:

• Cable set

• Micro RDC box

Description

The electrical installations consist of the cable set from A1 to A3 with mi-

cro RDC as well as the cable set from A4 to A6. The cable sets include

all the supply and control cables for the motors of axes 1 to 6 as well as

the cables for the protective circuit.

Micro RDCs are explained in more detail in the operating instructions of

the robot controller.

The interface for connecting the connecting cables to the robot is located

on the base frame at the rear of the robot. The interfaces X30, X31 and

ground conductor (PE) bolts are located on interface A1. The connecting

KR IONTEC

296/344 |

www.kuka.com

MA KR IONTEC V4 | Issued: 11.05.2021

Repair

Summary of Contents for IONTEC KR 20 R3100

Page 14: ...KR IONTEC 14 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Introduction...

Page 166: ...KR IONTEC 166 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Planning...

Page 188: ...KR IONTEC 188 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Start up and recommissioning...

Page 310: ...KR IONTEC 310 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Repair...

Page 340: ...KR IONTEC 340 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 KUKA Service...