5. Clean the lower mounting surface on the robot (

>>>

the machine frame mounting assembly" Page 180

6. Lower the robot vertically onto the mounting surface. Ensure that an

entirely vertical position is maintained in order to prevent damage to

the locating pins.

7. Insert 8 M20x60-8.8 Allen screws with conical spring washers.

8. Tighten 8 M20x60-8.8 Allen screws with a torque wrench in diagonally

opposite sequence. Increase the tightening torque to the specified val-

ue in several stages.

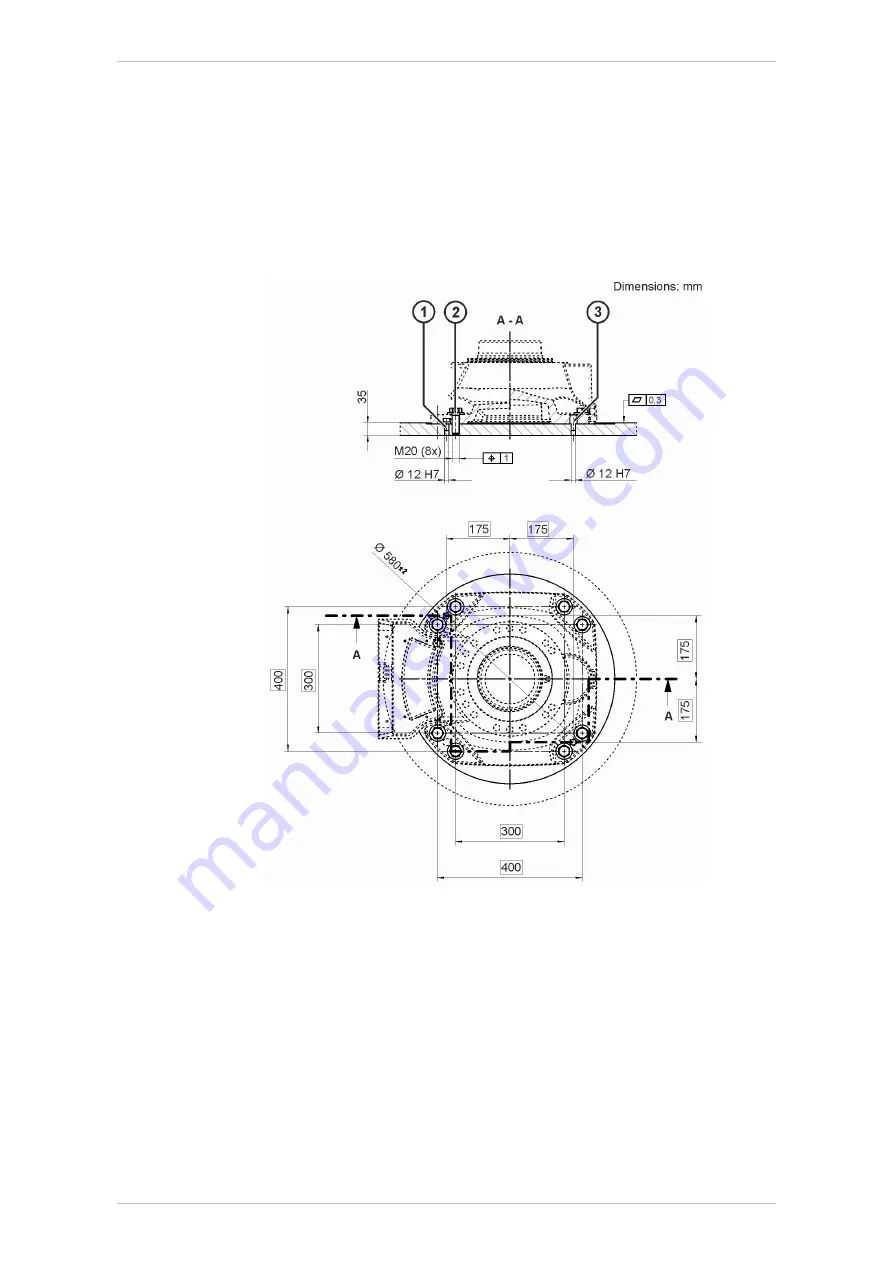

Fig. 7-7: Machine frame mounting, dimensioned drawing

1

Locating pin, cylindrical

2

M20x60-8.8-A2K hexagon screw with lock washer (8x)

3

Locating pin, flat-sided

7.3.3

Removing KR IONTEC fork slots

Procedure

1. Remove the M16x35-8.8 Allen screws and lock washers.

2. Remove the Load Lifting Attachment.

KR IONTEC

MA KR IONTEC V4 | Issued: 11.05.2021

www.kuka.com

| 181/344

Start-up

and

recommissioning

Summary of Contents for IONTEC KR 20 R3100

Page 14: ...KR IONTEC 14 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Introduction...

Page 166: ...KR IONTEC 166 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Planning...

Page 188: ...KR IONTEC 188 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Start up and recommissioning...

Page 310: ...KR IONTEC 310 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Repair...

Page 340: ...KR IONTEC 340 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 KUKA Service...