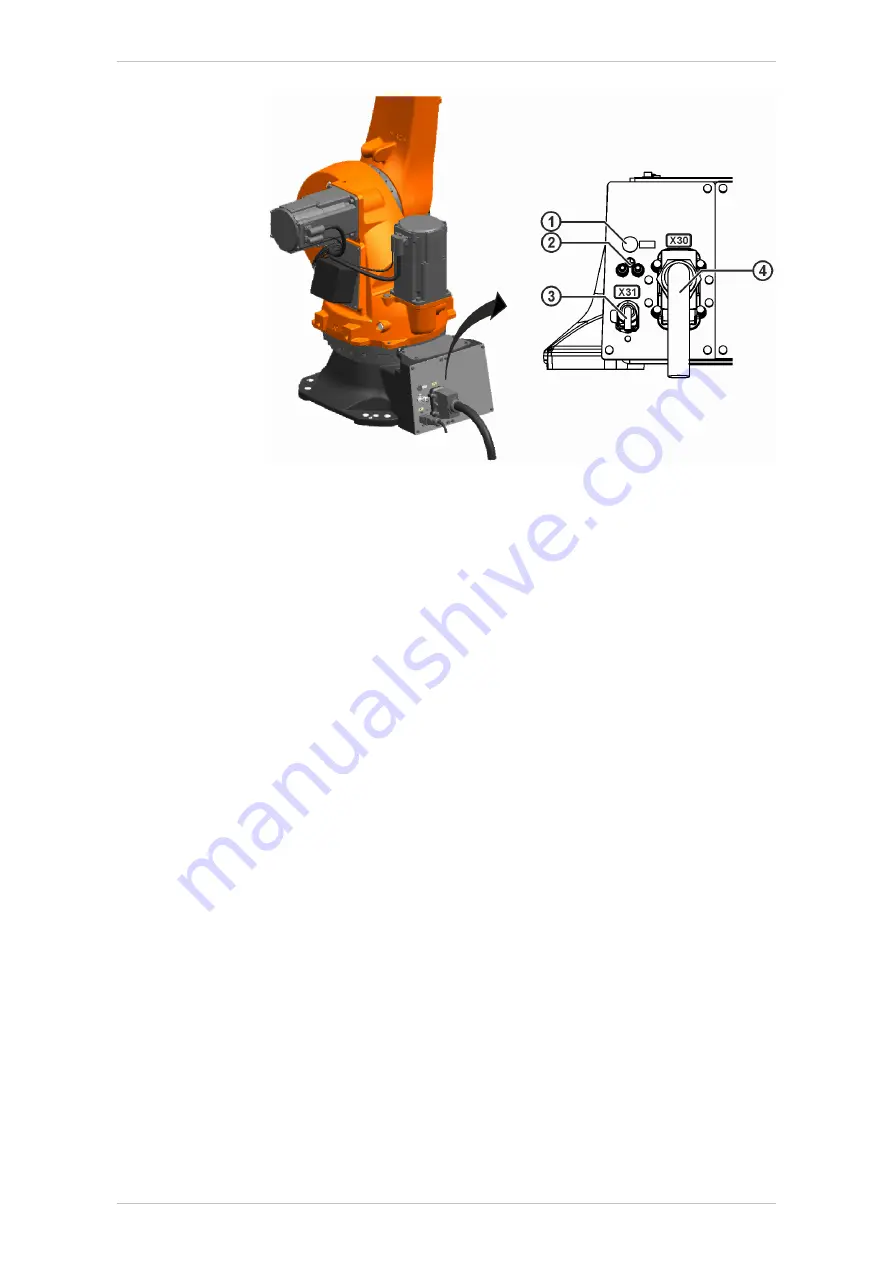

Fig. 7-9: Connecting the connecting cables

1

Connection for sealing air (for Foundry only)

2

Ground conductor (2x)

3

Data cable X31

4

Motor cable X30

7.3.5

Concluding work

The following concluding work must be carried out:

• If applicable, mount the tool.

• Start up the robot system in accordance with the chapter “Start-up and

recommissioning” in the operating instructions for the robot controller.

• Put the robot system into operation in accordance with the chapter

“Start-up and recommissioning” of the operating and programming in-

structions for the KUKA System Software (KSS).

7.4

Description of the connecting cables

Configuration

The connecting cables are used to transfer power and data between the

robot controller and the robot.

The connecting cables comprise:

• Motor cable

• Control cable

Interface

For the connection of the connecting cables between the robot controller

and the robot, the following connectors are available on the junction box-

es.

KR IONTEC

MA KR IONTEC V4 | Issued: 11.05.2021

www.kuka.com

| 183/344

Start-up

and

recommissioning

Summary of Contents for IONTEC KR 20 R3100

Page 14: ...KR IONTEC 14 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Introduction...

Page 166: ...KR IONTEC 166 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Planning...

Page 188: ...KR IONTEC 188 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Start up and recommissioning...

Page 310: ...KR IONTEC 310 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Repair...

Page 340: ...KR IONTEC 340 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 KUKA Service...