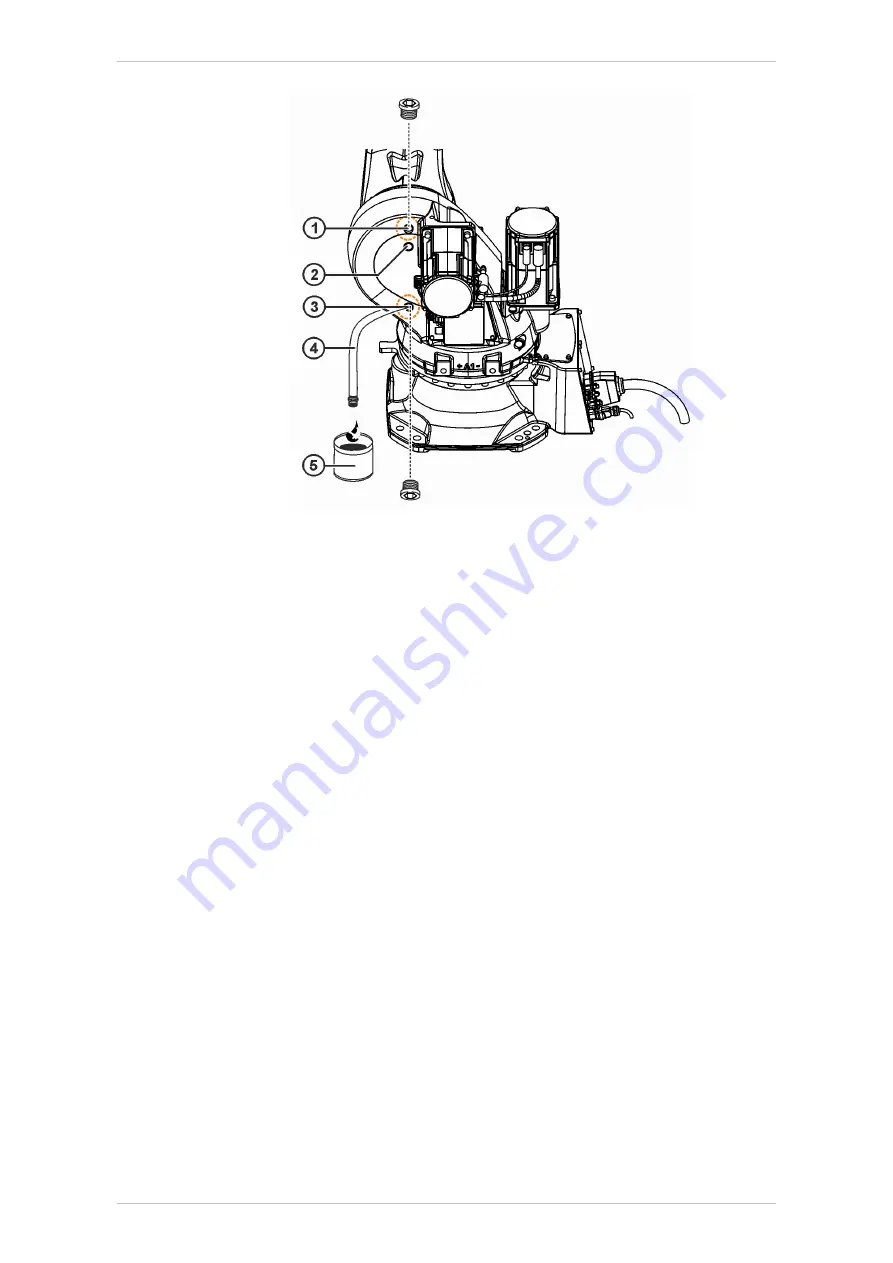

Fig. 8-6: Draining the gear oil from A2

1

M18x1.5 magnetic screw plug for venting

2

Inspection hole for floor installation

3

Oil drain hole with M18x1.5 magnetic screw plug

4

M18x1.5 oil drain tube

5

Collection receptacle

8.4.2

Filling gear unit A2 with gear oil

Procedure

1. Clean both M18x1.5 magnetic screw plugs and check the sealing ele-

ment; exchange magnetic screw plugs if damaged.

2. Connect the oil pump to the oil drain tube. The oil pump can also be

connected directly to the oil drain hole (

>>>

3. Unscrew the M18x1.5 magnetic screw plug from the inspection hole.

4. Fill the amount of oil from below up to the lower edge of the inspec-

tion hole using the oil pump.

5. Clean the M18x1.5 magnetic screw plug of the inspection hole and

check the sealing element; exchange if damaged.

Insert the M18x1.5 magnetic screw plug into the inspection hole and

tighten it; M

A

= 20 Nm.

6. Insert and tighten the upper M18x1.5 magnetic screw plug on the ro-

tating column; M

A

= 20 Nm.

7. Remove the oil pump from the oil drain hole or oil drain tube and

screw in M18x1.5 magnetic screw plug; M

A

= 20 Nm.

KR IONTEC

202/344 |

www.kuka.com

MA KR IONTEC V4 | Issued: 11.05.2021

Maintenance

Summary of Contents for IONTEC KR 20 R3100

Page 14: ...KR IONTEC 14 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Introduction...

Page 166: ...KR IONTEC 166 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Planning...

Page 188: ...KR IONTEC 188 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Start up and recommissioning...

Page 310: ...KR IONTEC 310 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Repair...

Page 340: ...KR IONTEC 340 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 KUKA Service...