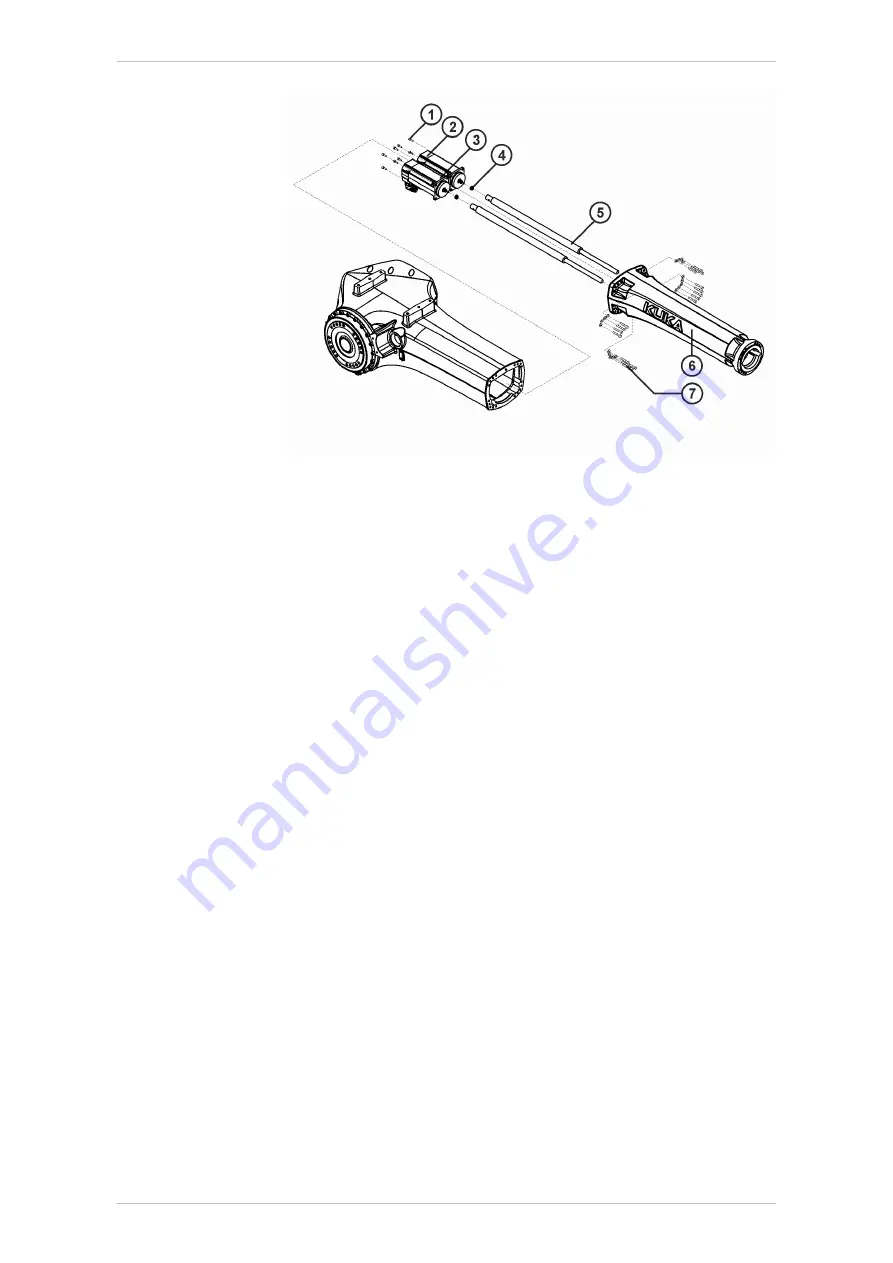

Fig. 9-40: KR 20 R3100 – Removing/installing motors A4 and A5

1

M5x14-8.8-A2K Allen screw (4x per motor)

2

Motor A4

3

Motor A5

4

Sinuous spring 0.25x11.43x15.88 (2x)

5

Connecting shaft R3100 (2x)

6

Arm extension

7

M6x35-8.8-A2K Allen screw with conical spring washer (18x)

9. Clean the surface between the in-line wrist with arm extension and the

arm and apply a thin but continuous coat of Drei Bond 5204 HV adhe-

sive.

10. Attach the in-line wrist with arm extension to the arm using 18 Allen

screws and tighten the screws with a torque wrench in diagonally op-

posite sequence. Increase the tightening torque to the specified value

in several stages.

11. Fasten the motor cable to the first holder at the marked position with a

cable strap.

12. Plug the plug connection A6 back together and fasten the holder (far

right position) using a cable strap.

13. Fasten both holders with 2 M6x12-8.8-A2K Allen screws each.

9.5.3.9

Installing motor A4

Procedure

1. If a new motor is to be installed, remove any corrosion protection prior

to installation.

2. Clean the toothing on connecting shaft A4 and check for wear.

In the case of damage and/or wear, connecting shaft A4 must be ex-

changed.

3. Apply a thin but continuous coat of Microlube GL 261 to the toothing

on connecting shaft A4.

KR IONTEC

MA KR IONTEC V4 | Issued: 11.05.2021

www.kuka.com

| 281/344

Repair

Summary of Contents for IONTEC KR 20 R3100

Page 14: ...KR IONTEC 14 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Introduction...

Page 166: ...KR IONTEC 166 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Planning...

Page 188: ...KR IONTEC 188 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Start up and recommissioning...

Page 310: ...KR IONTEC 310 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Repair...

Page 340: ...KR IONTEC 340 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 KUKA Service...