Installation, Connection, Exchange

16 of 26

Ro/Me/03/23 03.99.02 en

(2) Raise robot with fork lift truck or lifting tackle attached to three eyebolts on the rotating

column.

For reasons of safety, it is imperative for the lifting tackle to be attached to the

robot at the specified points. Risk of injury!

The transport instructions in the robot Doc. Module “Repair, General” must be

observed.

If the robot is transported by fork lift truck, the forks must be placed in the slots

in the base frame or the transport frame. It is forbidden to pick up the robot in

any other way using a fork lift truck!

(3) Lower robot (Fig. 10/3) vertically onto intermediate plates (5) or steel structure. If lifting

tackle is used, particular care must be taken to ensure exact vertical positioning in order

to avoid damaging the locating pins during this operation.

As the robot is lowered, the boreholes (2) must be aligned as accurately as pos-

sible with the two locating pins (1). If this operation is carried out inaccurately, it

is more likely that parts will be damaged.

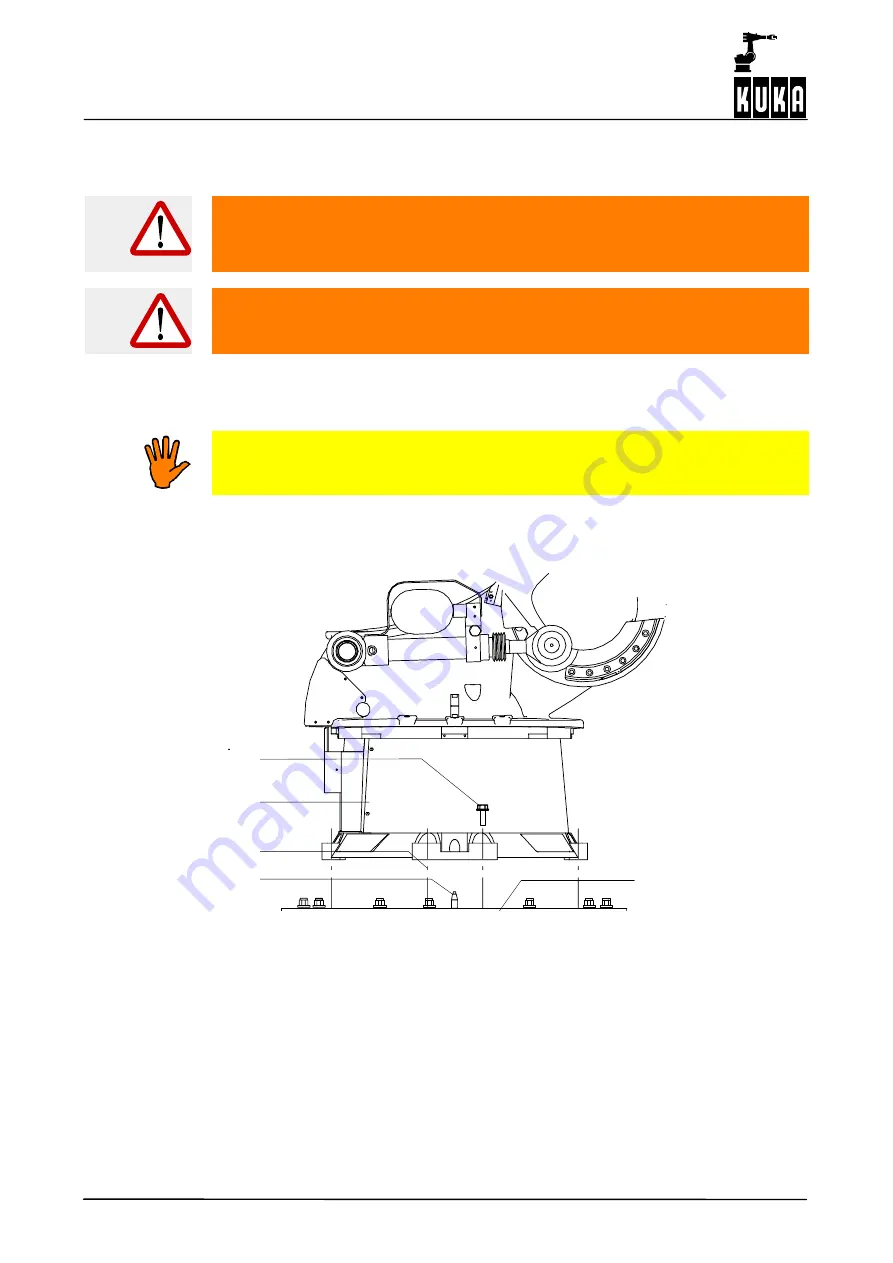

1

2

4

5

3

Fig. 10 Installing the robot on the floor

(4) Insert eight M24x100--8.8 ISO 4017 hexagon bolts (4) together with lock washers and

tighten them with a torque wrench in diagonally opposite sequence, increasing the tight-

ening torque to the specified value in several stages (M

A

= 700 Nm).