4

Installing and connecting the robot (continued)

19 of 26

Ro/Me/03/23 03.99.02 en

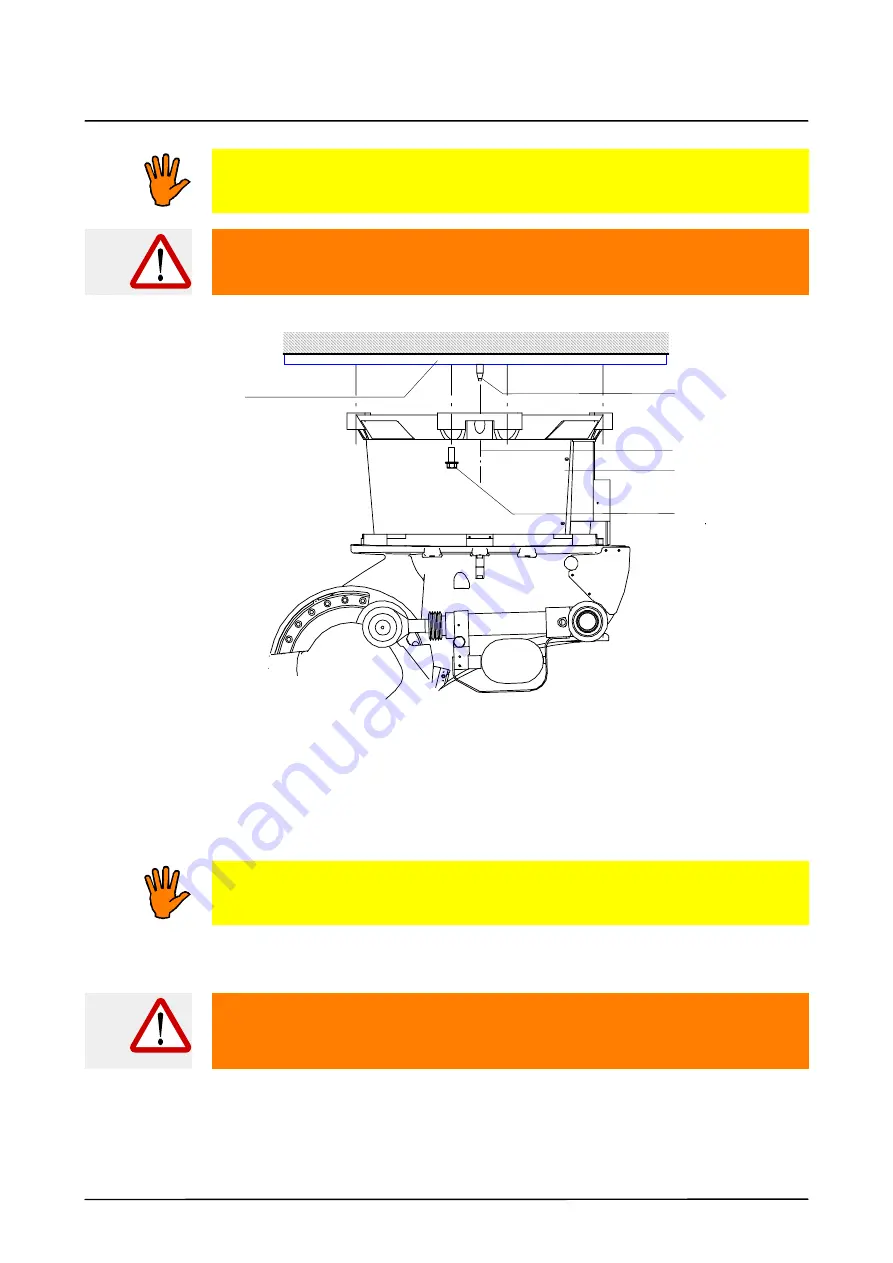

As the robot is lifted, the boreholes (2) must be aligned as accurately as pos-

sible with the two locating pins (1). If this operation is carried out inaccurately, it

is more likely that parts will be damaged.

As soon as the robot is in its exact position on the ceiling, it must be pressed

firmly against the ceiling until it is finally bolted to it.

1

2

4

5

3

Fig. 13 Installing the robot on the ceiling

(3) Insert eight M24x100--8.8 ISO 4017 hexagon bolts (4) together with lock washers and

tighten them with a torque wrench in diagonally opposite sequence, increasing the tight-

ening torque to the specified value in several stages (M

A

= 700 Nm).

Retighten M24x100--8.8 ISO 4017 hexagon bolts (4) after 100 hours of operation.

(4) Remove fork lift truck.

(5) Connect connecting cables.

Before performing the next step, it must be ensured that it is not possible for

anyone to be injured within the range of the slowly moving robot.

The robot may only be moved at manual traversing speed, with all applicable

safety rules and regulations being observed.