Hardware

22 of 70

Hardware R2.2.8 11.98.02 en

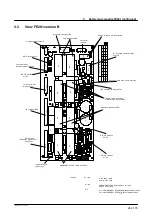

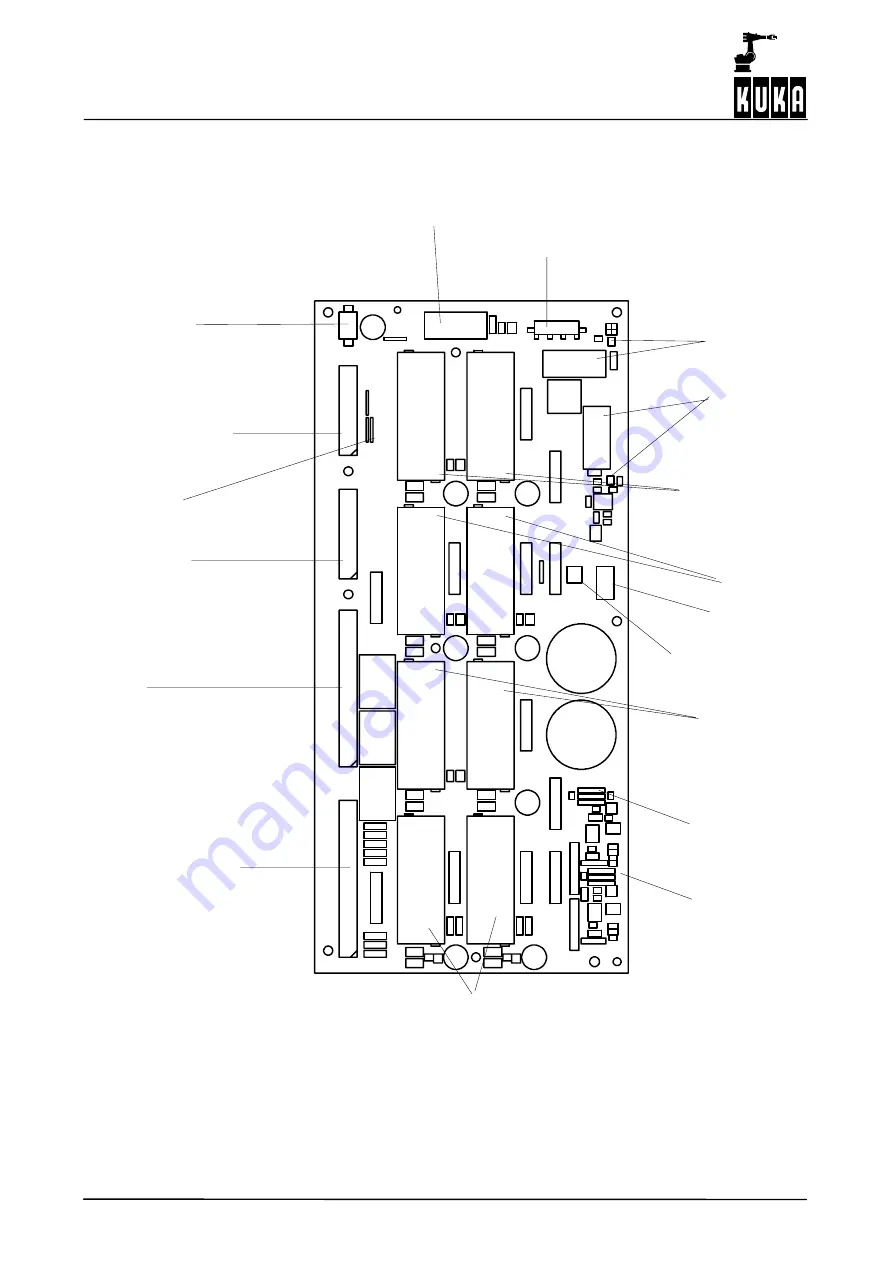

3.2

View FE201 version A

V1

6

V2

V11

V7

C6

C1

F3

R3

R14

V3

V12

F2

F1

R4

C2

V1

0

V1

4

V4

V1

V5

R7

V9

V8

R5

D1

C5

R1

3

R6

V6

R47

X9

21

R9

R1

2

R1

R2

X1

R10

X2

R1

8

F5

R11

R15

C7

F6

V13

V18

F7

R16

V17

F8

D2

F9

C10

R17

V15

R3

6

R8

C1

4

R20

V31

V34

X4

L11

R21

R22

X5

V32

V35

X6

R37

V3

3

L12

C8

R3

5

X9

23

L10

C3

C1

1

C9

V20

V19

V21

V23

R25

V2

2

R28

V2

4

R2

7

R2

6

R2

3

R2

4

F10

X9

22

V2

8

R19

C13

R33

D3

C15

C1

3

C1

2

V25

V28

R38

R34

V26

V29

V3

0

R32

R3

0

R39

V29

R31

V2

7

X8

X7

X9

25

R2

9

F11

X9

V3

4

V3

5

F4

R40

1

X9

24

R41

V3

8

C4

V3

7

X926

2

K3

K4

K5

K6

K8

K7

K1

3

K1

4

K1

K2

K9

X9

27

V3

9

Fig. 10

FE201 version A

”Drives ON” relay with LED

Connector

interface

Voltage supply connector

DIP--FIX switches

FK connector PM...

FK connector

FK connector

(Standard) interface X11

(VW) FE202

FK connector PM...

for external axes (optional)

X7--X9

for basic axes

“Drives ON” relays

of MFC with LED

”Test” relays with LED

”27 V voltage monitoring”

relays with LED

DIP--FIX switches

X1--X3

DIP--FIX switches

X4--X6

”Automatic” relays with LED

LED V39 main switch operation

Connector X927

”Safety” relays

”EMERGENCY STOP” relays with LEDs

MFC

main switch operation

with LEDs

Summary of Contents for KR C1

Page 1: ...Hardware R2 2 8 11 98 02 en 1 of 70 SOFTWARE KR C1 Hardware Release 2 2...

Page 30: ...Hardware 30 of 70 Hardware R2 2 8 11 98 02 en Fig 13 Circuit diagram X931 X604...

Page 32: ...Hardware 32 of 70 Hardware R2 2 8 11 98 02 en Fig 15 Inputs...

Page 34: ...Hardware 34 of 70 Hardware R2 2 8 11 98 02 en...

Page 35: ...35 of 70 Hardware R2 2 8 11 98 02 en...