○

Depending on the condition of wheels, bolts, nuts and other fastening parts, fastening with PTS may damage bolts.

( Hereinafter this condition will be referred to as "abnormal fastening").

○

This machine has the function to immediately detect this "abnormal fastening" and shut down to prevent bolts and

other parts from damages.

○

When "abnormal fastening" is detected, "CH1"( CHECK1 ) is displayed on the controller and the machine stops.

○

When "CH1" ( abnormal fastening ) is displayed, check the following.

【1】If "CH1"(abnormal fastening) is displayed, please remove the nut.

(Caution)

If the wheel nut is made up of the inner nut and the outer nut, please make sure to fasten the inner nut

with recommended torque after loosening the outer nut.

If "CH1" is displayed, do not continue fastening. Loosen the bolt / nut first.

Otherwise the bolt may be stretched or the wheel may be deformed.

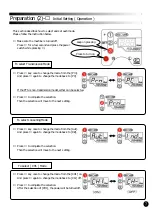

【2】 In case of JIS type ( 8 nuts )

(1) Whether the wheel center is misaligned to the wheel bolt.

(2) Whether there are any damages on the seating surface of

wheels, nuts, and or thread face.

● Replace the parts when there are damages or

unevenness of seating face.

(3) Whether the wheel bolt is extended ( stretched ).

● If so, replace the bolt with new one.

(4) Whether excessive grease is applied.

● If so, wipe off the grease gently.

● In particular, excessive grease application on the

aluminum wheel is a cause of excessive axial force

generation*. Pay full attention to the amount or the

portion of grease applied.

Refer automobile manufacturer's instruction.

*Axial Force : Force to pull the bolt (Fastening Force).

(5) Whether the torque is appropriate.

● Refer automobile manufacturer's instruction.

Warning

Troubleshooting (3)-①

[CH1]

Center

Wheel Bolt

Wheel Hole

Misalignment

of Center

Unevenness of wheel seating surface

(exmaple of iron wheel)

Unevenness of inner nut seating surface

(exmaple of iron inner nut)